Zirconium-based tough nanocrystalline alloy material and preparation method thereof

A technology of nanocrystalline alloys and zirconium-based amorphous alloys, applied in nanotechnology, metal rolling, nanotechnology, etc., can solve the problems of restricting application range and prospects, low critical cooling rate, high amorphous forming ability, etc., and achieve Excellent thermal stability, improved toughness, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

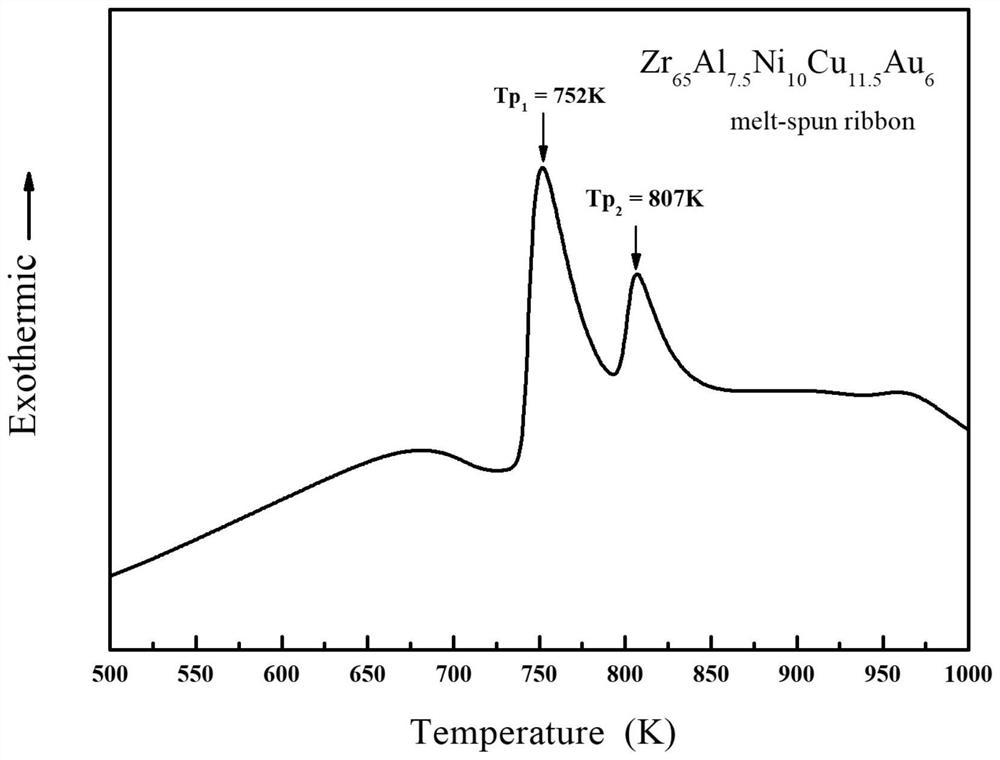

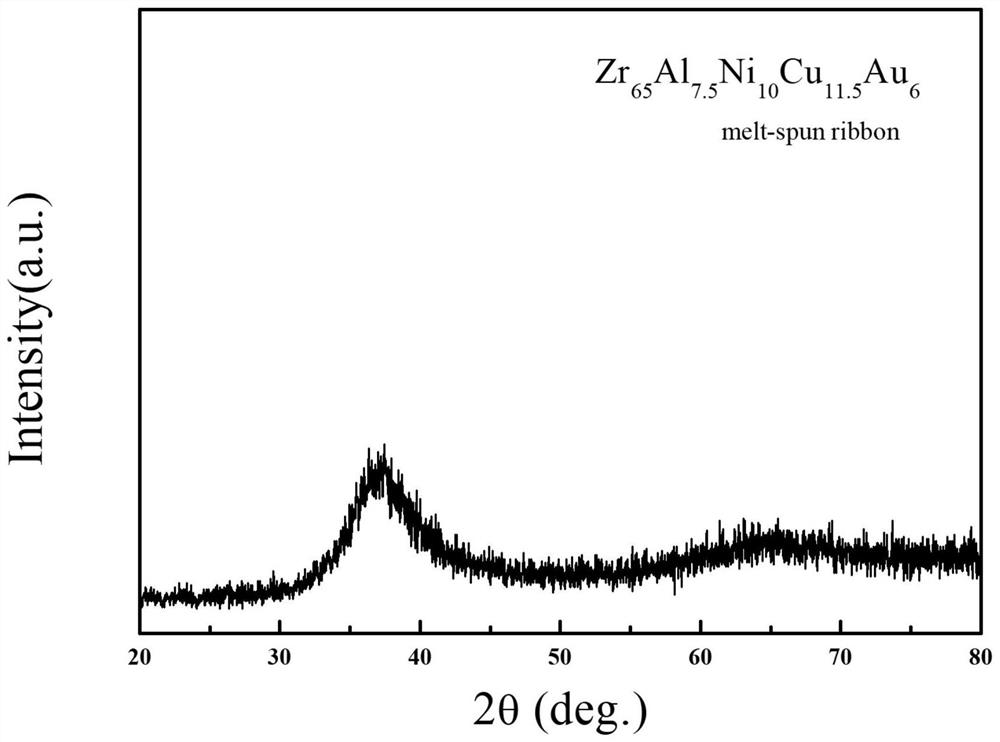

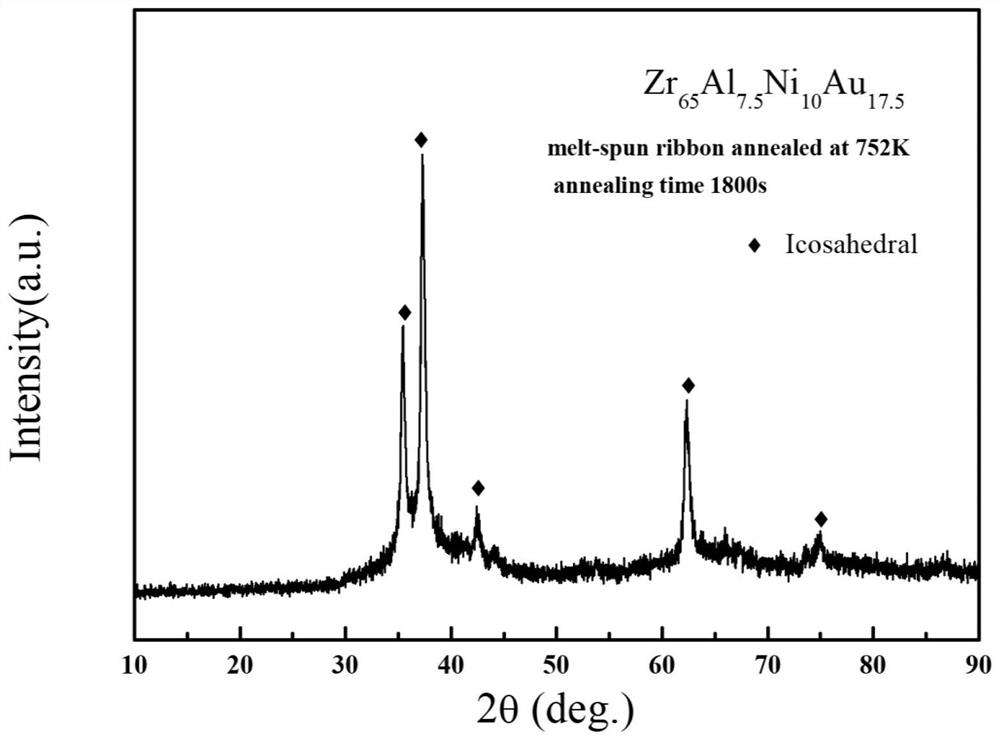

[0054] A zirconium-based ductile nanocrystalline alloy Zr 65 Al 7.5 Ni 10 Cu 11.5 Au 6 The ultra-low temperature rolling preparation method is prepared according to the following steps:

[0055] Step 1, prepare raw materials according to the composition expression of the above zirconium-based alloy, convert atomic percentage into mass percentage to prepare raw materials, weigh the corresponding mass and mix for use. See Table 1 for raw material purity and manufacturer.

[0056] Step 2, place the raw materials prepared in step 1 in a vacuum arc melting furnace, and evacuate to 3×10 -3When Pa, filled with argon gas, under the protection of argon gas, the raw material was heated to complete melting and uniform after 6 times of smelting, and then cooled to room temperature of 25 °C to make a master alloy ingot.

[0057] Step 3, break the master alloy ingot into 5 pieces, try to ensure that the size is uniform, each piece is 1.5g, and put the small pieces of alloy into alcohol...

Embodiment 2

[0068] A zirconium-based ductile nanocrystalline alloy Zr 65 Al 7.5 Ni 10 Cu 7.5 Au 10 The ultra-low temperature rolling preparation method is prepared according to the following steps:

[0069] Step 1, prepare raw materials according to the composition expression of the above zirconium-based alloy, convert atomic percentage into mass percentage to prepare raw materials, weigh the corresponding mass and mix for use. See Table 1 for raw material purity and manufacturer.

[0070] Step 2, place the raw materials prepared in step 1 in a vacuum arc melting furnace, and evacuate to 3×10 -3 When Pa, filled with argon gas, under the protection of argon gas, the raw material was heated to complete melting and uniform after 6 times of smelting, and then cooled to room temperature of 25 °C to make a master alloy ingot.

[0071] Step 3, break the master alloy ingot into 5 pieces, try to ensure that the size is uniform, each piece is 2g, and put the small pieces of alloy into alcohol ...

Embodiment 3

[0082] A zirconium-based ductile nanocrystalline alloy Zr 65 Al 7.5 Ni 10 Cu 2.5 Au 15 The ultra-low temperature rolling preparation method is prepared according to the following steps:

[0083] Step 1, prepare raw materials according to the composition expression of the above zirconium-based alloy, convert atomic percentage into mass percentage to prepare raw materials, weigh the corresponding mass and mix for use. See Table 1 for raw material purity and manufacturer.

[0084] Step 2, place the raw materials prepared in step 1 in a vacuum arc melting furnace, and evacuate to 3×10 -3 When Pa, filled with argon gas, under the protection of argon gas, the raw material was heated to complete melting and uniform after 6 times of smelting, and then cooled to room temperature of 25 °C to make a master alloy ingot.

[0085] Step 3, break the master alloy ingot into 4 pieces, try to ensure that the size is uniform, each piece is 1.5g, and put the small pieces of alloy into alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com