Compound edible fungus oral liquid and preparation process thereof

An edible fungus oral liquid and compound technology, applied to bacteria used in food preparation, food processing, medical preparations containing active ingredients, etc., can solve the problems of affecting health care effects and single types of edible fungi, so as to improve nutrition and health care Value, delicious taste, good antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

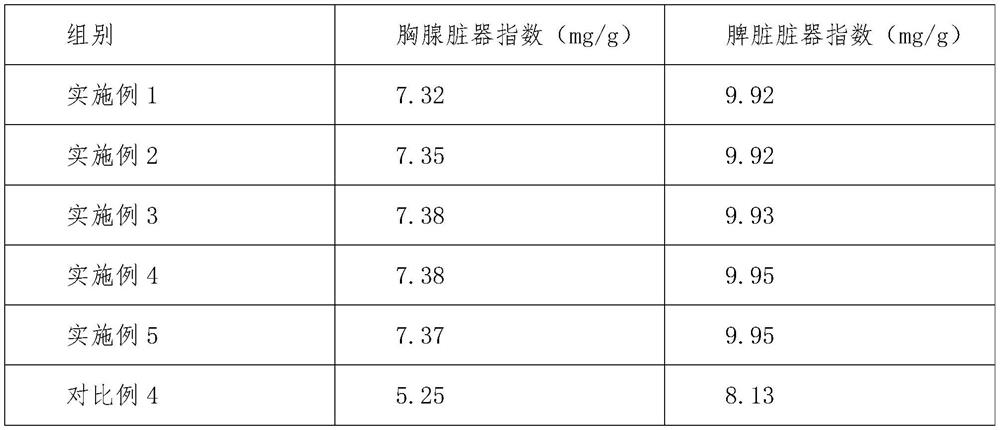

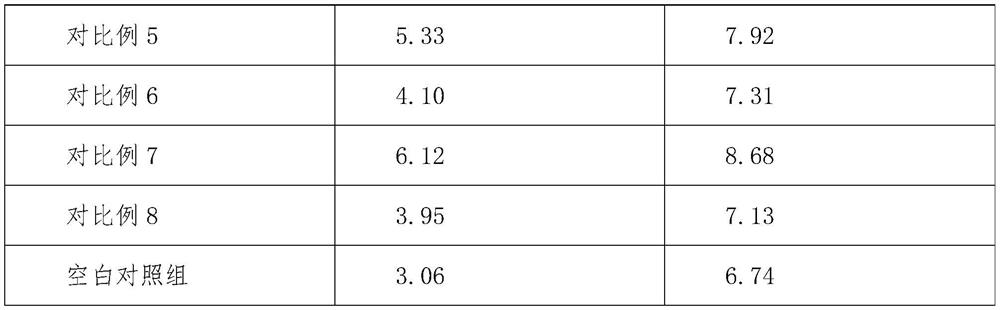

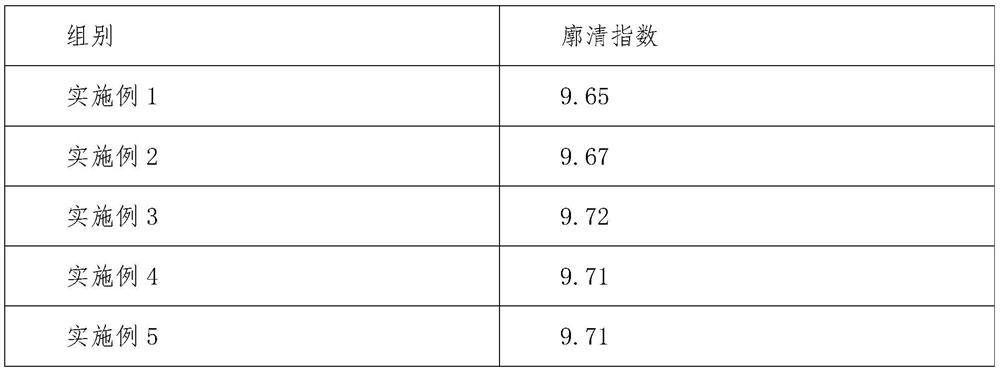

[0024] Weigh the following raw materials by weight according to the ratio: 18 parts of bovine mushrooms, 8 parts of shiitake mushrooms, 8 parts of frondosa frondosa, 10 parts of Poria cocos, 6 parts of green mushroom extract, 4 parts of truffle extract, morel enzymolysis 3 parts of wolfberry fruit, 16 parts of jujube seed, 7 parts of angelica, 8 parts of lily, 13 parts of tangerine peel, 6 parts of licorice, 8 parts of mixed fermentation broth of chicory and puhuang, 7 parts of mixed fermentation broth of perilla and propolis, select cattle The fresh fruiting bodies of tongue fungus, shiitake mushroom, Grifola frondosa and Poria cocos are cleaned and placed in a freeze dryer for 36 hours, then crushed and passed through a 200-mesh sieve to obtain a mixed dry powder; soak the mixed dry powder with 10 times of water, and then add compound enzyme , the amount of enzyme is to add papain 10U, cellulase 8U and pectinase 3U per gram of raw material, enzymolysis at 36°C for 2 hours to ...

Embodiment 2

[0031] Weigh the following raw materials by weight according to the proportion: 19 parts of bovine mushrooms, 9 parts of shiitake mushrooms, 9 parts of frondosa frondosa, 13 parts of poria cocos, 8 parts of green mushroom extract, 5 parts of truffle extract, morel enzymolysis 5 parts of Chinese wolfberry fruit, 17 parts of jujube seed, 8 parts of angelica, 9 parts of lily, 14 parts of tangerine peel, 7 parts of licorice, 9 parts of mixed fermentation broth of chicory and cattail root, 8 parts of mixed fermentation broth of perilla and propolis, select cow The fresh fruiting bodies of tongue fungus, shiitake mushroom, Grifola frondosa, and Poria cocos are cleaned and placed in a freeze dryer for 39 hours, then crushed and passed through a 200-mesh sieve to obtain a mixed dry powder; add 11 times the water to infiltrate the mixed dry powder, and then add compound enzyme , the dosage of the enzyme is to add 10U of papain, 8U of cellulase and 3U of pectinase per gram of raw materia...

Embodiment 3

[0038] Weigh the following raw materials by weight according to the proportion: 20 parts of bovine mushroom, 10 parts of shiitake mushroom, 10 parts of frondosa frondosa, 15 parts of poria cocos, 9 parts of green mushroom extract, 6 parts of truffle extract, morel enzymolysis 6 parts of wolfberry fruit, 20 parts of jujube seed, 10 parts of angelica, 10 parts of lily, 15 parts of tangerine peel, 8 parts of licorice, 11 parts of chicory-puhuang mixed fermentation broth, 10 parts of perilla-propolis mixed fermentation broth, Select the fresh fruit bodies of bovine tongue mushroom, shiitake mushroom, maitake frondosa, and poria cocos, clean them, place them in a freeze dryer for 42 hours, and then crush them through a 200-mesh sieve to obtain a mixed dry powder; soak the mixed dry powder with 12 times of water, and then add Compound enzyme, the amount of enzyme is 11U of papain, 9U of cellulase and 4U of pectinase per gram of raw material, enzymolysis at 36°C for 2.5h to obtain enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com