Preparation method and application of mordenite with high silica-alumina ratio

A technology of mordenite and high silicon-to-aluminum ratio, which is applied in the field of catalysis, can solve the problems of incomplete utilization of raw materials, emission of pollution, surplus of reaction materials, etc., and achieve the effects of improving the production of mordenite, avoiding pollution and reducing preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0094] Step 1: Weigh a certain amount of sodium hydroxide, sodium aluminate, silica sol, cetyltrimethylammonium bromide and mix with water, stir evenly, and then transfer to a stainless steel high-pressure hydrothermal reaction kettle for pre-crystallization , to obtain a high silicon-aluminum ratio precursor solution with a hydroxonite structure. Step 2: mixing sodium hydroxide, sodium aluminate and water, then adding silica sol and tetraethylammonium hydroxide, stirring and aging to obtain a structure-oriented sol. Step 3: The silicon-aluminum precursor solution and the structure-oriented sol obtained in step 2 are mixed in a certain proportion, stirred evenly, and then transferred to a stainless steel high-pressure hydrothermal reaction kettle for crystallization; after the crystallization is completed, the product is press-filtered to obtain the filtrate after crystallization , the product was washed with deionized water until neutral, dried at 120°C for 12 hours, and calc...

Embodiment 7

[0096] Raw materials used, proportioning and test conditions are identical with step one, step two, step three and step four in embodiment 1. Wherein, the water in step two is completely replaced by the filtrate after crystallization obtained in step three in embodiment 1.

[0097] Among them, during the preparation of samples 1 to 7, the molar amount of raw materials, precrystallization temperature and time of the silica-alumina precursor with hydroxonite and mordenite are shown in Table 1 for details.

[0098] During the preparation of samples 1-7, the molar amounts of raw materials, crystallization temperature and time of the structure-oriented sol and comparative sample 1 are shown in Table 2 for details.

[0099] See Table 3 for the mass ratio of the silicon-aluminum precursor mixed with the structure-directed sol in samples 1 to 7 and the silicon-aluminum molar ratio of the mordenite sample obtained after the final test of comparative sample 1.

[0100] Table 1 Preparat...

Embodiment 8

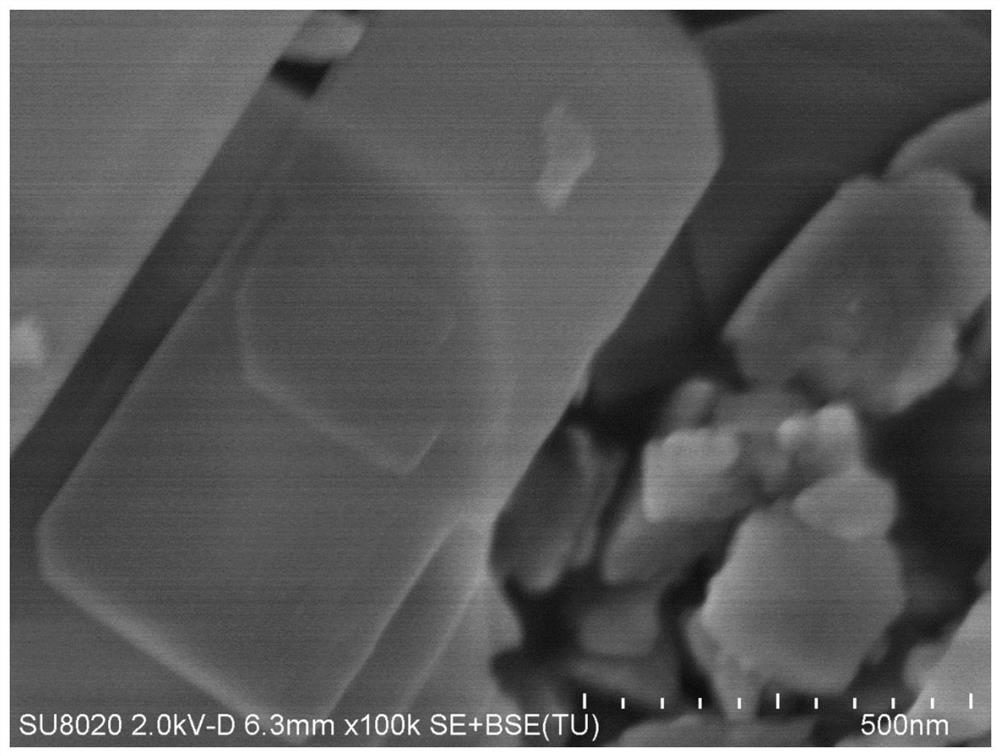

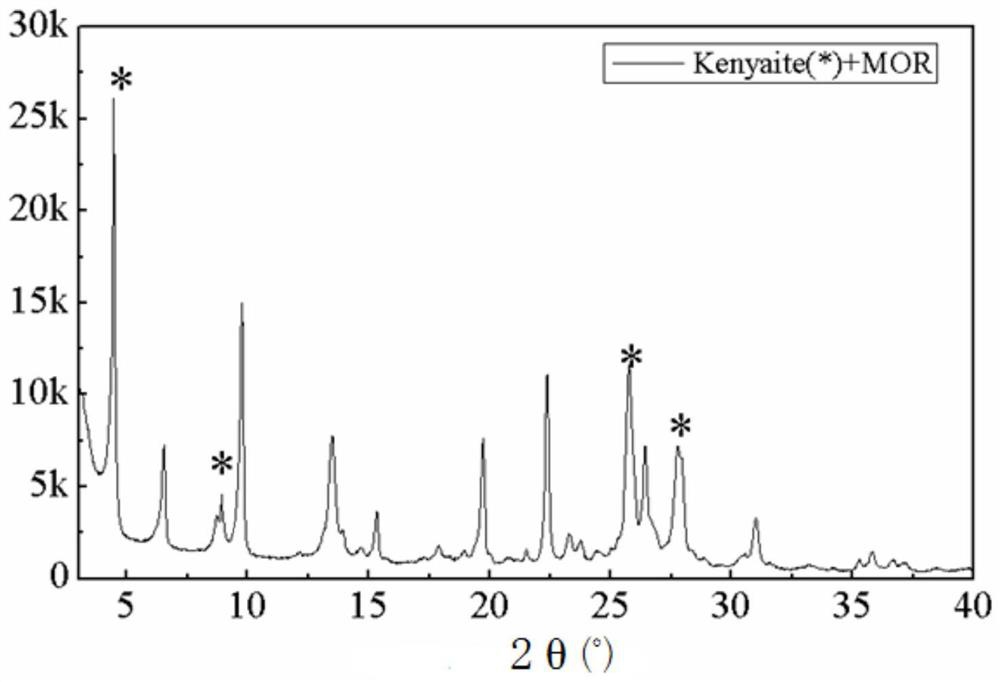

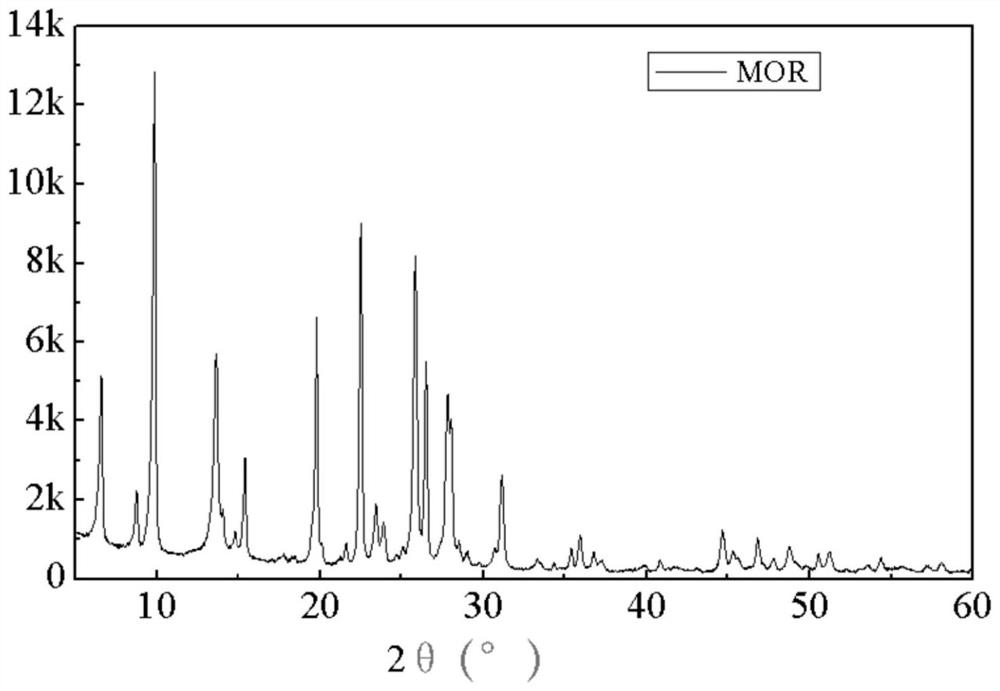

[0137] Scanning electron microscope analysis (SEM) was performed on the high-silicon-aluminum-ratio mordenite samples prepared in the above examples. The instrument used in the SEM test was a Hitachi SU8020 field emission scanning electron microscope with an accelerating voltage of 2 kV.

[0138] Taking the sample 1 prepared in Example 1 as a typical example, figure 1 It is the SEM photo (500nm) of the silicon-aluminum precursor corresponding to sample 1, Figure 4 It is the SEM photograph (1 μm) of sample 1. Depend on figure 1 It can be seen that the sample has two zeolite structures of different sizes, of which the hydroxysilica zeolite is much larger in size. Depend on Figure 4 It can be seen that the finally obtained high-silicon-aluminum-ratio mordenite has a short columnar packing structure with a size of 30-60×200-500 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com