Lithium-doped high-entropy oxide battery negative electrode material as well as preparation and application methods thereof

A battery negative electrode and negative electrode material technology, applied in the direction of chemical instruments and methods, battery electrodes, active material electrodes, etc., can solve the problems of low electronic conductivity, low charge-discharge reversible specific capacity, poor cycle stability, etc., to achieve simple process, Production and application promotion, high crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

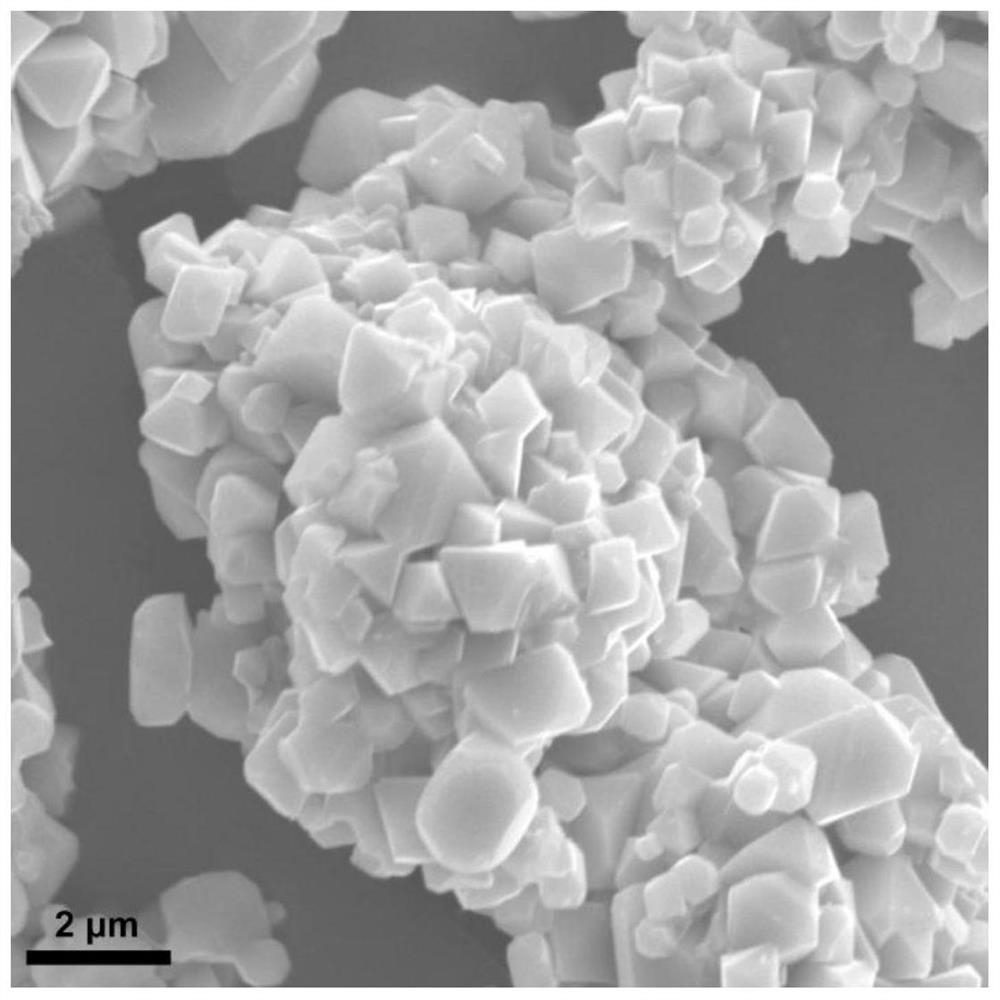

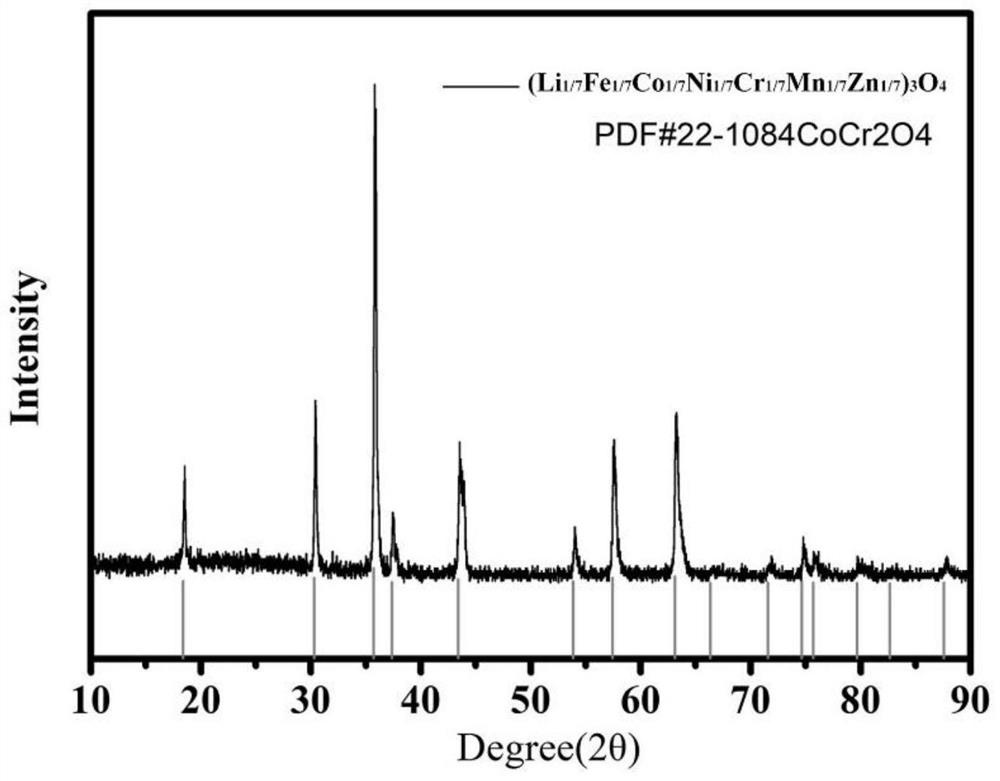

[0042] A lithium-doped high-entropy oxide battery negative electrode material, the chemical formula is (Li 1 / 7 Fe 1 / 7 co 1 / 7 Ni 1 / 7 Cr 1 / 7 mn 1 / 7 Zn 1 / 7 ) 3 o 4 ;

[0043] The particle size of the lithium-doped high-entropy oxide battery negative electrode material is 3-5 μm;

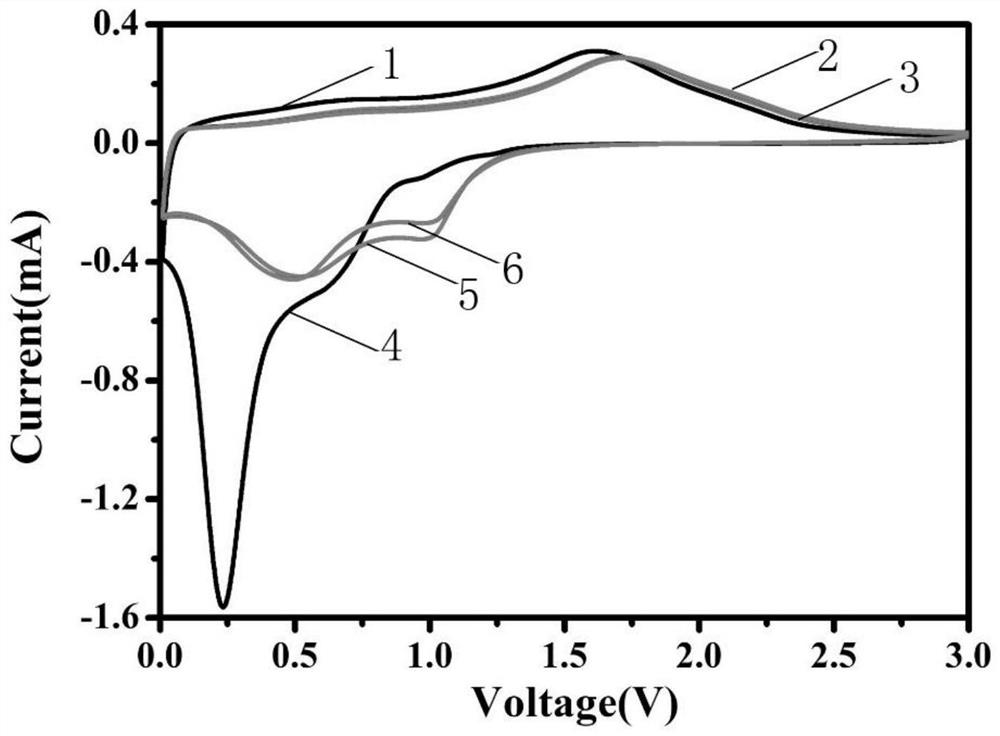

[0044] The negative electrode material of the lithium-doped high-entropy oxide battery is tested by the half-cell of the lithium-ion battery, and at 100mAhg -1 The first reversible specific capacity is 687.2mAh g under the current density -1 , after 100 cycles, the specific capacity is 518.3mAh g -1 ;

[0045] The above-mentioned preparation method of a lithium-doped high-entropy oxide battery negative electrode material comprises the following steps:

[0046] Step 1: Take Fe with a purity of 99% 2 o 3 (0.005mol, 0.8065g), ZnO (0.01mol, 0.822g), Cr 2 o 3 (0.005mol, 0.768g), NiO (0.01mol, 0.754g), MnO 2 (0.01mol, 0.878g) and Co 3 o 4 (0.0033mol, 0.803g) obtain material A after powder...

Embodiment 2

[0055] A lithium-doped high-entropy oxide battery negative electrode material, the chemical formula is (Li 1 / 6 Fe 1 / 6 co 1 / 6 Ni 1 / 6 Zn 1 / 6 mn 1 / 6 ) 3 o 4 ;

[0056] The particle size of the lithium-doped high-entropy oxide battery negative electrode material is 5-8 μm;

[0057] The negative electrode material of the lithium-doped high-entropy oxide battery is tested by the half-cell of the lithium-ion battery, and at 100mAhg -1 Under the current density, the first reversible specific capacity is 720.2mAhg -1 , after 100 cycles, the specific capacity is 604.6mAhg -1 ;

[0058] The above-mentioned preparation method of a lithium-doped high-entropy oxide battery negative electrode material comprises the following steps:

[0059] Step 1: Take Fe with a purity of 99% 2 o 3 (0.005mol, 0.8065g), ZnO (0.01mol, 0.822g), NiO (0.01mol, 0.754g), MnO 2 (0.01mol, 0.878g) and Co 3 o 4 (0.0033mol, 0.803g) obtain material A after powder mixing, and in A, add the Li that purity ...

Embodiment 3

[0068] A lithium-doped high-entropy oxide battery negative electrode material, the chemical formula is (Li 1 / 6 Zn 1 / 6 co 1 / 6 Ni 1 / 6 Cr 1 / 6 mn 1 / 6 ) 3 o 4 ;

[0069] The particle size of the lithium-doped high-entropy oxide battery negative electrode material is 3-5 μm;

[0070] The negative electrode material of the lithium-doped high-entropy oxide battery is tested by the half-cell of the lithium-ion battery, and at 100mAhg -1 Under the current density, the first reversible specific capacity is 545.9mAhg -1 , after 100 cycles, the specific capacity is 460.0mAhg -1 ;

[0071] The above-mentioned preparation method of a lithium-doped high-entropy oxide battery negative electrode material comprises the following steps:

[0072] Step 1: Take ZnO (0.01mol, 0.822g) with a purity of 99%, Cr 2 o 3 (0.005mol, 0.768g), NiO (0.01mol, 0.754g), MnO 2 (0.01mol, 0.878g) and Co 3 o 4 (0.0033mol, 0.803g) obtain material A after powder mixing, and in A, add the Li that purity i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com