A kind of gentamicin fermentation waste liquid solid-liquid separation treatment method

A technology of fermentation waste liquid and gentamicin, which is applied in separation methods, filtration separation, filtration treatment, etc., can solve the problems of solid-liquid separation of Qingda fermentation waste liquid, reduce the amount of slag produced, and increase the filtration speed , the effect of large granularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

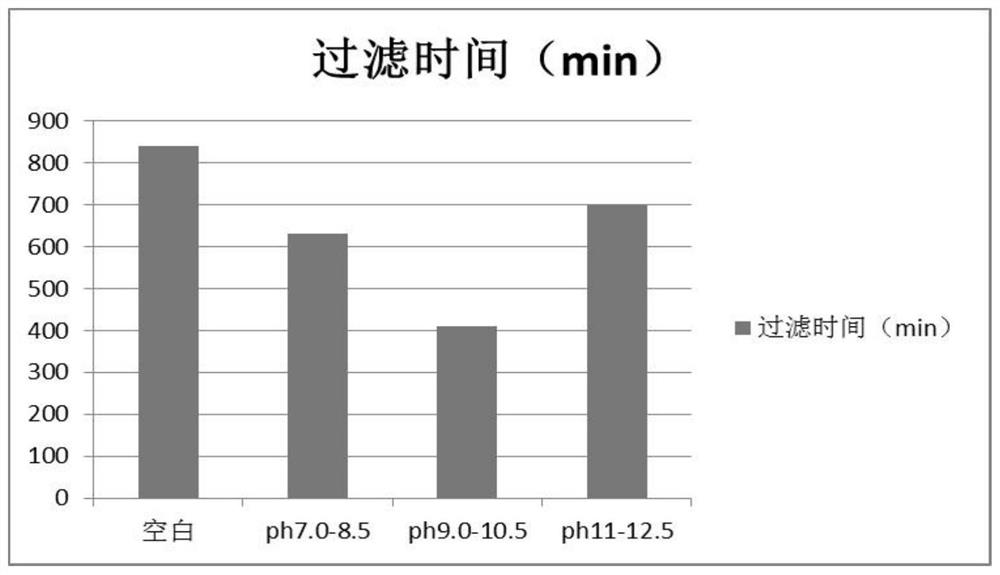

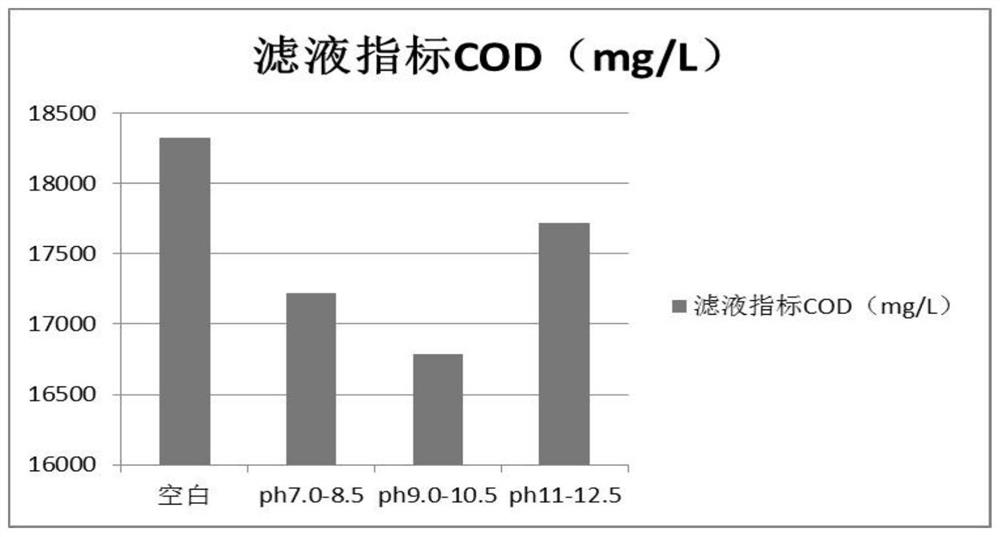

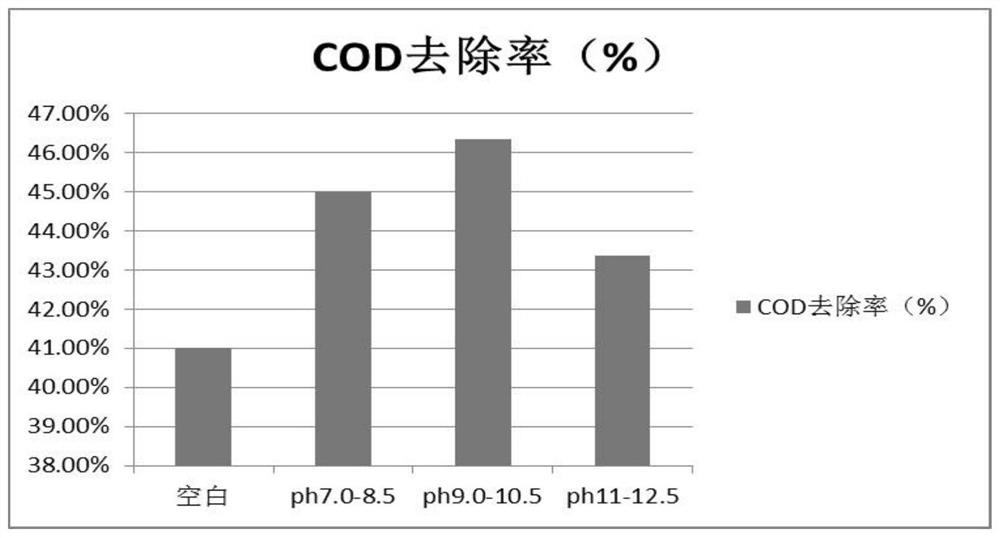

[0047] Adjust the different pH values of Qingda fermentation waste liquid to study the effect on the filtration speed. The experimental design is as follows:

[0048] Experiment 1: Blank (the gentamicin fermentation waste liquid was directly subjected to plate and frame filtration).

[0049] Experiment 2: Add calcium oxide to adjust the pH to 7.0-8.5 while stirring the gentamicin fermentation waste liquid, and perform plate and frame filtration after stirring for 5 minutes.

[0050] Experiment 3: The gentamicin fermentation waste liquid was stirred by adding calcium oxide to adjust the pH to 9.0-10.5, stirred for 5 minutes, and then plate-and-frame filtered.

[0051] Experiment 4: Add calcium oxide to adjust the pH to 11-12.5 in the gentamicin fermentation waste liquid while stirring, and perform plate and frame filtration after stirring for 5 minutes.

[0052] Record the filtration time, take a sample to detect the COD of the filtrate, calculate the COD removal rate, and d...

Embodiment 2

[0056]Adding calcium oxide to the gentamicin fermentation waste liquid under stirring to adjust the pH to 9.0-10.5, adding lovastatin waste residue as a filter aid (lovastatin waste residue 1%, V / W, moisture ≤ 20%), Then filter through the plate and frame, and study the influence of the filtering speed.

[0057] The experimental design is as follows:

[0058] Experiment 5: Blank (add calcium oxide to adjust the pH to 9.0-10.5 in the gentamicin fermentation waste liquid while stirring, and perform plate and frame filtration after stirring for 5 minutes).

[0059] Experiment 6: After adding calcium oxide to adjust pH 9.0-10.5 to gentamicin fermentation waste liquid under stirring state, add lovastatin waste residue as filter aid (lovastatin waste residue 1%, V / W, moisture≤ 20%), and then filtered through the plate frame.

[0060] Record the filtration time, take a sample to detect the COD of the filtrate, calculate the COD removal rate, and detect the water content of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com