Modified activated sludge and application thereof

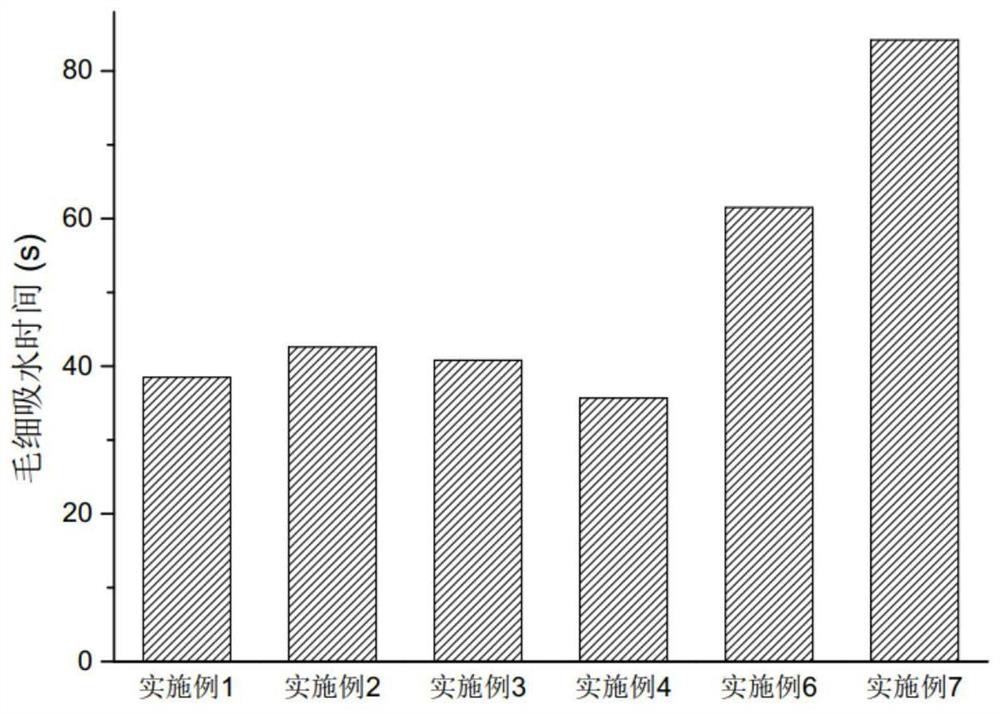

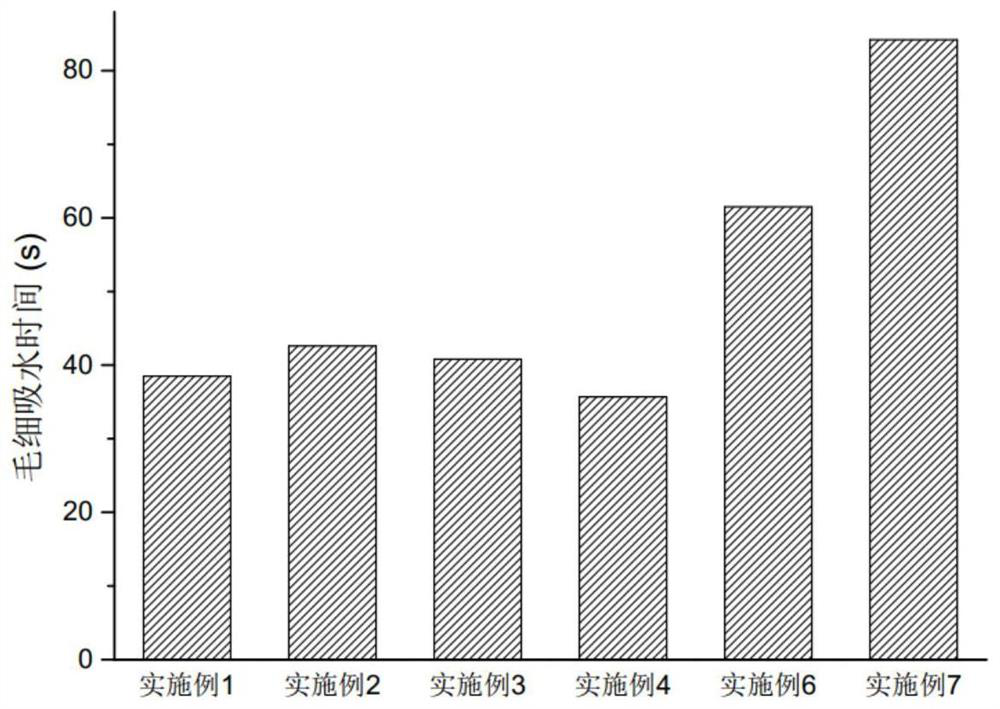

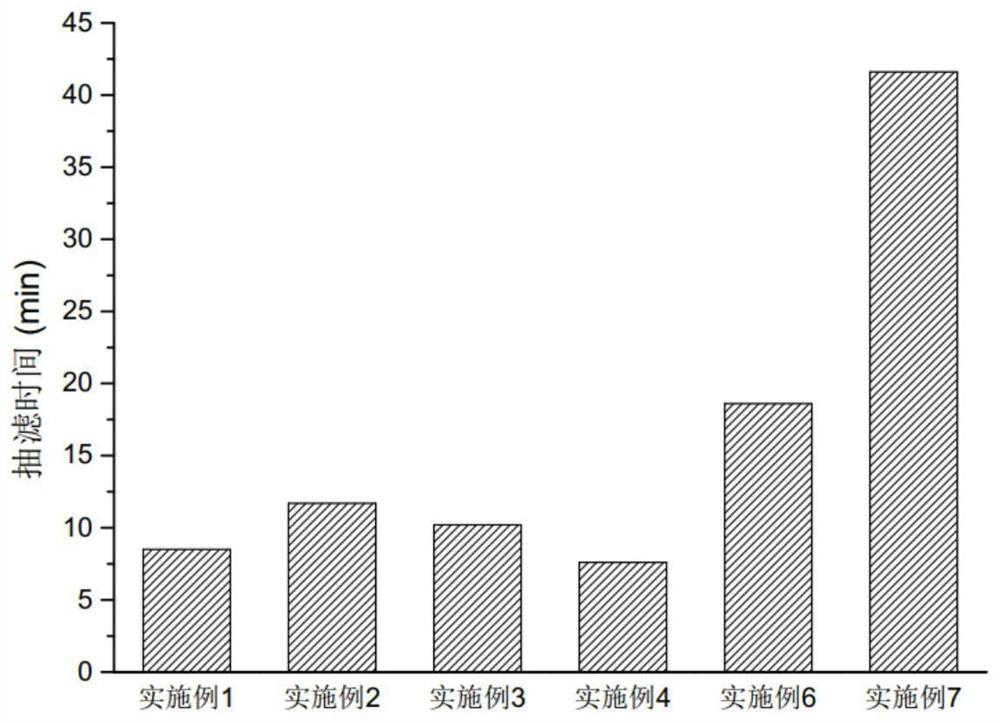

An activated sludge and modified technology, applied in sludge treatment, water/sludge/sewage treatment, water pollutants, etc. Pollution, large one-time investment and other problems, to achieve the effect of reducing capillary water absorption time, reducing filtration specific resistance, and improving dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for modifying activated sludge, comprising:

[0045]S1: Add cattail powder to ferric chloride solution with a concentration of 10wt%, the dosage ratio of cattail powder and ferric chloride solution is 100mL:15g, shake and soak for 24h, filter, dry at 105°C for 2h, and then dry in N 2 Atmosphere, carbonization at 480°C for 4 hours, naturally cooled to room temperature, then washed with distilled water, and finally dried at 105°C for 2 hours to obtain iron-loaded cattail activated carbon;

[0046] S2: Add iron-loaded cattail activated carbon into the activated sludge, the dosage of iron-loaded cattail activated carbon in the activated sludge is 140mg / L, mix and stir for 4min, and dehydrate the filter cake at 105℃ Dry for 5 hours, grind through an 80-mesh sieve to obtain activated sludge particles;

[0047] S3: Add the activated sludge particles to a nitric acid solution with a concentration of 10wt% to acidify and modify for 6 hours. The ratio of acid solution t...

Embodiment 2

[0049] A method for modifying activated sludge, comprising:

[0050] S1: Add cattail powder to ferric chloride solution with a concentration of 8wt%, the dosage ratio of cattail powder and ferric chloride solution is 100mL:12g, shake and soak for 36h, filter, dry at 110°C for 1.5h, and then 2 Atmosphere, carbonization at 500°C for 5h, naturally cooled to room temperature, then washed with distilled water, and finally dried at 110°C for 1.5h to obtain iron-loaded cattail activated carbon;

[0051] S2: Add iron-loaded cattail activated carbon into the activated sludge, the dosage of iron-loaded cattail activated carbon in the activated sludge is 120mg / L, mix and stir for 2min, after dehydration by plate and frame filter press, filter cake at 110℃ Dry for 4 hours, grind through a 50-100 mesh sieve to obtain activated sludge particles;

[0052] S3: Add the activated sludge particles into the hydrochloric acid solution with a concentration of 8wt% to acidify and modify for 6 hours...

Embodiment 3

[0054] A method for modifying activated sludge, comprising:

[0055] S1: Add cattail powder to ferric chloride solution with a concentration of 14wt%, the dosage ratio of cattail powder and ferric chloride solution is 100mL:17g, shake and soak for 15h, filter, dry at 105°C for 2h, and then dry in N 2 Atmosphere, carbonization at 550°C for 3 hours, naturally cooled to room temperature, then washed with distilled water, and finally dried at 105°C for 2 hours to obtain iron-loaded cattail activated carbon;

[0056] S2: Add iron-loaded cattail activated carbon into the activated sludge, the dosage of iron-loaded cattail activated carbon in the activated sludge is 200mg / L, mix and stir for 5min, and dehydrate the filter cake at 105°C after dehydration by plate and frame filter press Dry for 5 hours, grind through a 100-mesh sieve to obtain activated sludge particles;

[0057] S3: Add the activated sludge particles to a sulfuric acid solution with a concentration of 15wt% to acidif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com