Green and efficient composite sludge dewatering process of natural polymeric flocculant and clay material

A natural polymer and sludge dehydration technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of not being able to significantly improve sludge dehydration, and achieve improved sludge dehydration effect , reduce dosage and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Attapulgite (commercially available) and laboratory-made 3-chloro-2-hydroxypropyltrimethylammonium chloride modified starch (CS) were used for sludge dewatering experiments. For the preparation method of CS, see: (Flocculation and antimicrobial properties of a cationized starch, Zhouzhou Liu, Mu Huang, Aimin Li, Hu Yang, Water Research, 2017, 119, 57-66.)

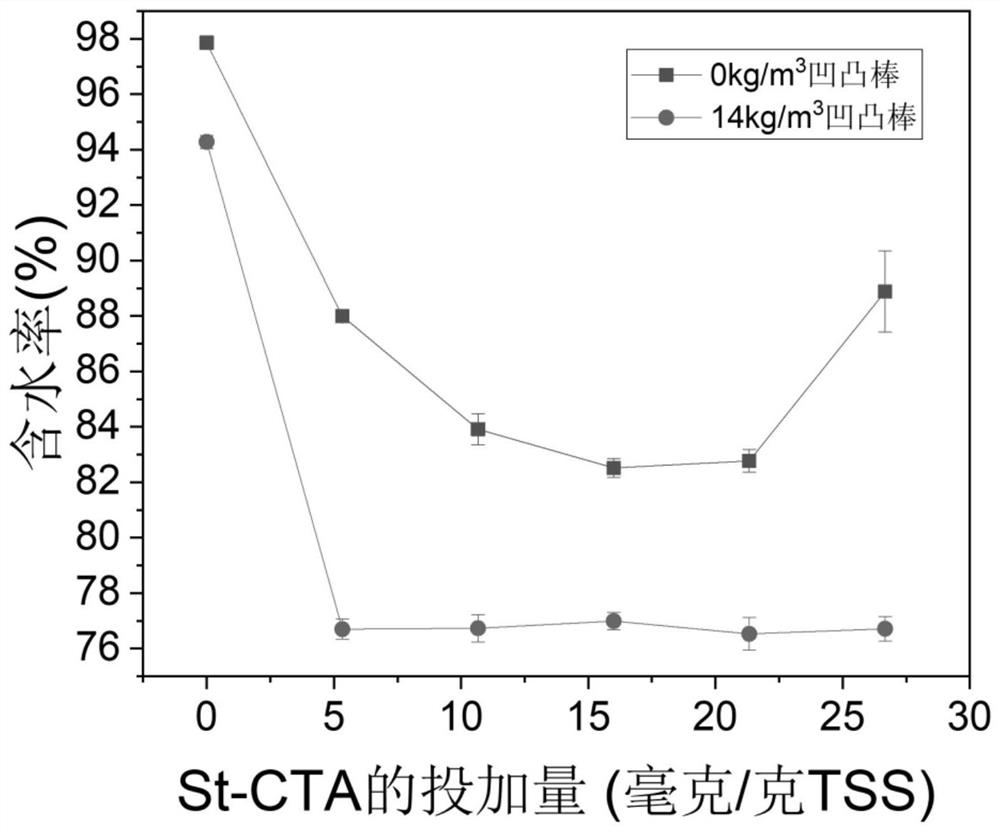

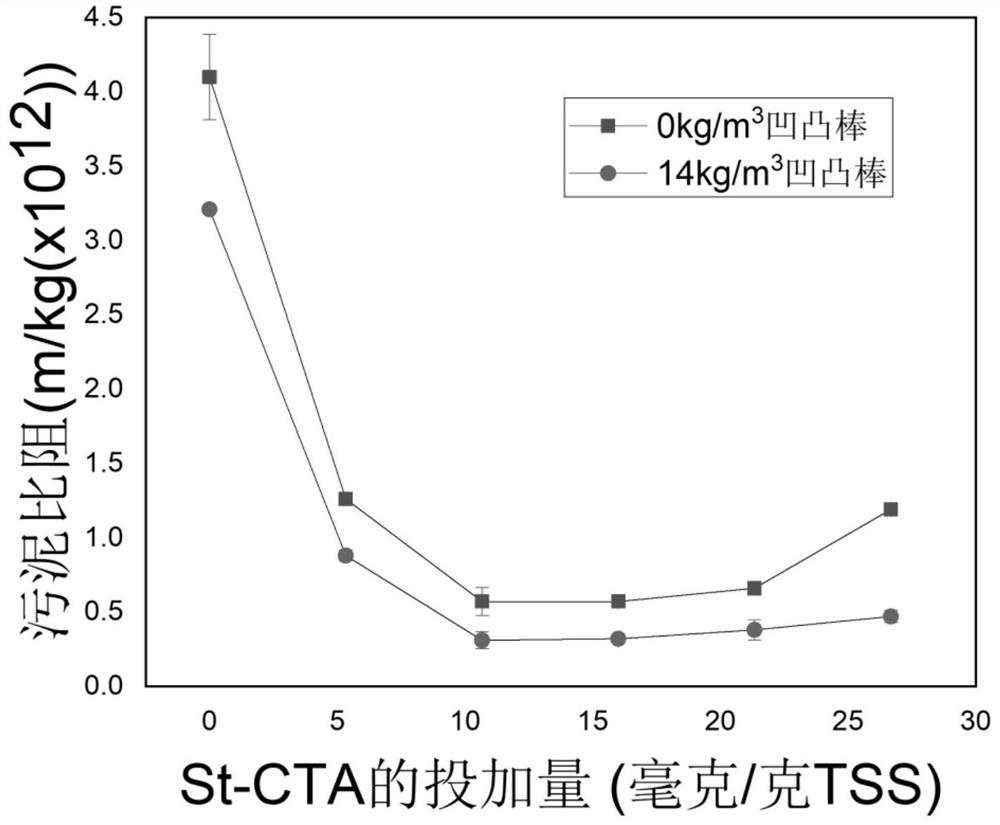

[0035] Taking the sludge of Nanjing Sewage Treatment Plant as the experimental object, firstly add different doses of CS, stir quickly for 1 minute, stir slowly for 1 minute, then add different doses of attapulgite, stir quickly for 30 seconds, stir slowly for 210 seconds, and let stand for 5 minutes Finally, use a vacuum pump to perform suction filtration for 6 minutes, and measure the moisture content of the sludge cake after conditioning, the specific resistance of the sludge, etc. figure 1 is the dewatering effect of the flocculant on the actual sludge. It can be seen from the figure that when the amount of flocc...

Embodiment 2

[0037] Using attapulgite (commercially available) and laboratory-made CS-DML (Evaluation of hydrophobically associating cationic starch-based flocculants in sludge dewatering, Pan Hu, Shaohang Shen, Hu Yang, Scientific Reports, 2021, 11, 11819(1-13) .) Conduct sludge dewatering experiments. Sludge from Nanjing Wastewater Treatment Plant was used as the treated water sample. The amount of attapulgite is 14kg / m 3 , starch grafted polyacrylic acid consumption is 2.0mg / L, and its dehydration effect is not as good as embodiment 1.

Embodiment 3

[0039] Attapulgite (commercially available) and laboratory-made CS-DMC (The influence of hydrophobicity onsludge dewatering associated with cationic starch-based flocculants, Pan Hu, Shaohang Shen, Donghua Zhao, Hua Wei, Jun Ge, Feiyue Jia, Xiangxiang Zhang, Hu Yang, Journal of Environmental Management, 2021, 296, 113218(1-10).). Sludge from Nanjing Wastewater Treatment Plant was used as the treated water sample. The amount of attapulgite is 6kg / m 3 , CMC-g-PDMC consumption is 0.2mg / L, and its dehydration effect is not as good as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com