Preparation method of polyvinylidene fluoride modified membrane, and polyvinylidene fluoride modified membrane and application thereof

A technology of polyvinylidene fluoride and polyethyleneimine, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of expensive reaction equipment, harsh film-forming conditions, and many types of reagents, and achieve hydrophilic modification The effect is obvious and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

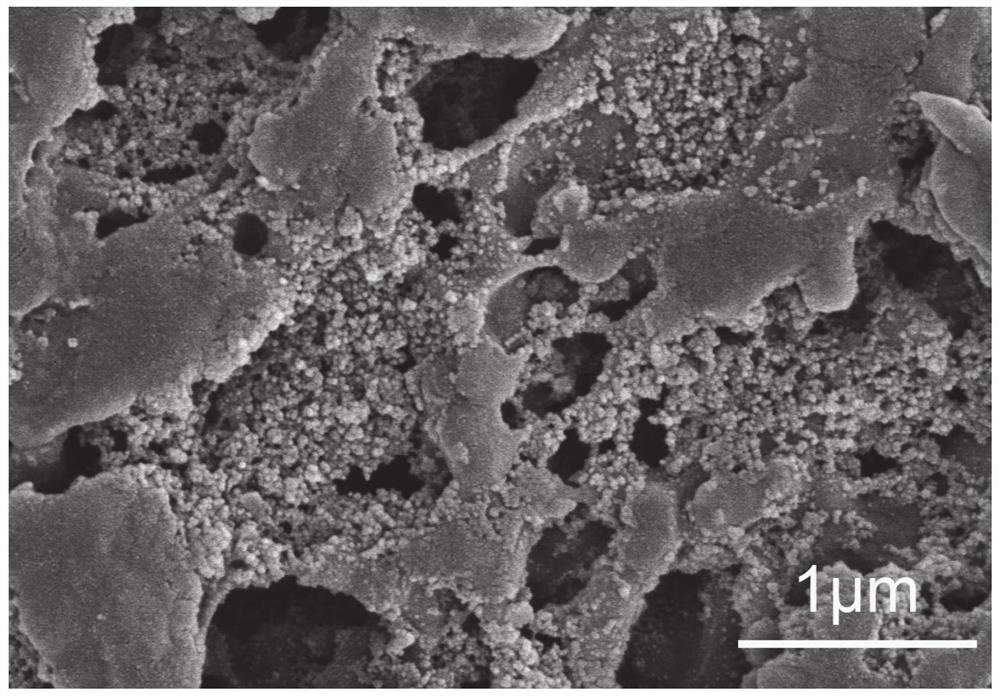

Image

Examples

Embodiment 1

[0048] A method for preparing a hydrophilic polyvinylidene fluoride modified membrane for oil-water emulsion separation, comprising the following steps:

[0049] 1) Put a commercial polyvinylidene fluoride microfiltration membrane (hereinafter referred to as the original PVDF membrane) (average pore size is 0.22 μm) into a beaker, add absolute ethanol, infiltrate at room temperature for 2 hours to activate the pores, take out the membrane before use Wash with ultrapure water three times;

[0050] 2) Immerse the pretreated polyvinylidene fluoride membrane in step 1) into a ferric ion solution (concentration: 1 mg / mL) for a rapid stirring reaction for 5 minutes, and wash off the unstable ferric ions on the membrane surface with ultrapure water;

[0051] 3) The film obtained in step 2) is immersed in a tannic acid solution, and polyethyleneimine is added dropwise to the tannic acid solution until the pH of the solution=7.8, and the concentrations of the tannic acid and polyethyle...

Embodiment 2

[0074] A method for preparing a hydrophilic polyvinylidene fluoride modified membrane for oil-water emulsion separation, comprising the following steps:

[0075] 1) Put the original PVDF membrane into a beaker, add absolute ethanol, infiltrate at room temperature for 1 hour to activate the pores, take out the membrane and wash it with ultrapure water three times before use;

[0076] 2) Immerse the pretreated polyvinylidene fluoride membrane in step 1) into a ferric ion solution (concentration: 1 mg / mL) for rapid stirring reaction for 10 minutes, and wash off the unstable ferric ions on the membrane surface with ultrapure water;

[0077] 3) Immerse the film obtained in step 2) into a tannic acid solution, and add polyethyleneimine dropwise to the tannic acid solution until the pH of the solution=7.8, and the concentrations of tannic acid and polyethyleneimine are respectively 1 mg / mL, 2mg / mL, open the reaction at room temperature for 6 hours, take out the membrane, wash it wit...

Embodiment 3

[0090] A method for preparing a hydrophilic polyvinylidene fluoride modified membrane for oil-water emulsion separation, comprising the following steps:

[0091] 1) Put the original PVDF membrane into a beaker, add absolute ethanol, infiltrate at room temperature for 2 hours to activate the pores, take out the membrane and wash it with ultrapure water three times before use;

[0092] 2) Immerse the pretreated polyvinylidene fluoride membrane in step 1) into a ferric ion solution (concentration: 1 mg / mL) and react with rapid stirring for 15 minutes, and wash off the unstable ferric ions on the surface of the membrane with ultrapure water;

[0093] 3) The film obtained in step 2) is immersed in a tannic acid solution, and polyethyleneimine is added dropwise to the tannic acid solution until the pH of the solution=7.8, and the concentrations of the tannic acid and polyethyleneimine are respectively 4mg / mL, 0.5mg / mL, open the reaction at room temperature for 4 hours, take out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com