Wastewater treatment agent and preparation method and application thereof

A wastewater treatment agent and surfactant technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the effect of wastewater treatment agent needs to be improved, the single activated carbon adsorption cost is high, Complex wastewater components, etc., to achieve the effect of enhancing the flocculation effect, improving the adsorption effect, and improving the removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

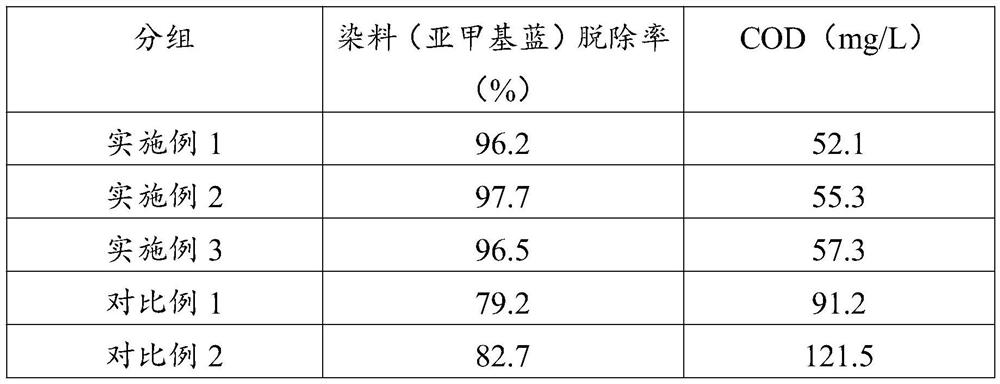

Examples

Embodiment 1

[0027] A kind of waste water treatment agent, comprises the raw material of following weight: graphene adsorbent 50kg, activated carbon 25kg, surfactant 0.5kg and corn cob 15kg; Wherein, graphene adsorbent comprises carboxylated graphene oxide and carbonyl iron graphene oxide compound things.

[0028] In order to further optimize the technical scheme: the mass ratio of carboxylated graphene oxide and carbonyl iron graphene oxide composite is 4:1.

[0029] The preparation method comprises the following steps:

[0030] 1) Take activated carbon and corn cob, mix and pulverize through a 200-mesh sieve;

[0031] 2) Mix carboxylated graphene oxide and carbonyl iron graphene oxide composite, surfactant and water, add pulverized activated carbon and corncobs, stir at 65°C for 0.5h, and dry to obtain a wastewater treatment agent.

[0032] In order to further optimize the technical scheme: the preparation method of carboxylated graphene oxide: the aqueous solution of graphene oxide, s...

Embodiment 2

[0038] A kind of waste water treatment agent, comprises the raw material of following weight: graphene adsorbent 80kg, activated carbon 30kg, surfactant 1kg and corncob 20kg; Wherein, graphene adsorbent comprises carboxylated graphene oxide and carbonyl iron graphene oxide compound .

[0039] In order to further optimize the technical scheme: the mass ratio of carboxylated graphene oxide and carbonyl iron graphene oxide composite is 4.5:1.

[0040] The preparation method comprises the following steps:

[0041] 1) Take activated carbon and corn cob, mix and pulverize through a 200-mesh sieve;

[0042] 2) Mix carboxylated graphene oxide and carbonyl iron graphene oxide composite, surfactant and water, add pulverized activated carbon and corncobs, stir at 70°C for 0.5h, and dry to obtain a wastewater treatment agent.

[0043] In order to further optimize the technical scheme: the preparation method of carboxylated graphene oxide: the aqueous solution of graphene oxide, sodium h...

Embodiment 3

[0049] A kind of waste water treatment agent, comprises the raw material of following weight: graphene adsorbent 100kg, activated carbon 35kg, surfactant 3kg and corncob 25kg; Wherein, graphene adsorbent comprises carboxylated graphene oxide and carbonyl iron graphene oxide compound .

[0050] In order to further optimize the technical scheme: the mass ratio of carboxylated graphene oxide and carbonyl iron graphene oxide composite is 5:1.

[0051] The preparation method comprises the following steps:

[0052] 1) Take activated carbon and corn cob, mix and pulverize through a 200-mesh sieve;

[0053] 2) Mix carboxylated graphene oxide and carbonyl iron graphene oxide composite, surfactant and water, add pulverized activated carbon and corncobs, stir at 75°C for 1 hour, and dry to obtain a wastewater treatment agent.

[0054] In order to further optimize the technical scheme: the preparation method of carboxylated graphene oxide: the aqueous solution of graphene oxide, sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com