Magnetic carbon composite material for remedying heavy metal contaminated soil and preparation method thereof

A composite material and soil-contaminated technology, applied in the field of magnetic carbon composite materials and preparation, can solve the problems of poor acid resistance and complicated preparation process, and achieve the effects of strong acid resistance, soil improvement and fertility increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

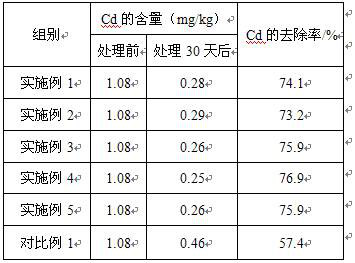

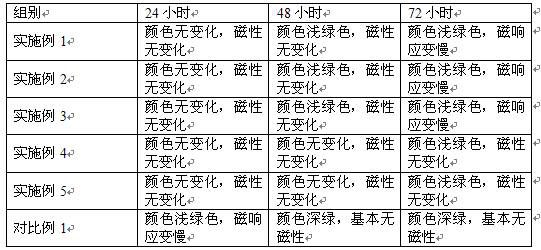

Examples

Embodiment 1

[0038] A method for preparing a magnetic carbon composite material for repairing heavy metal-contaminated soil, comprising the steps of:

[0039] S1. Preparation of modified raw materials:

[0040] S11. Preparation of magnetically modified biochar material: FeCl 2 • 4H 2 O and FeCl 3 •6H 2 Under the protection of nitrogen, O is mixed according to the molar ratio of 1:1 to form an iron salt mixture, and then add biochar and water to mix evenly, so that the biochar can absorb ferrous and ferric salts, and naturally filter out the liquid to obtain Adsorb the biochar of ferrous iron salt and ferric salt, then add dropwise ammonia water with a mass concentration of 25%, the reaction temperature is 60°C, and the reaction time is 2h; after washing with water, a magnetically modified biochar material is obtained;

[0041] S12. Preparation of β-cyclodextrin modified starch: add β-cyclodextrin and tapioca starch into water to make a suspension, heat up and stir to gelatinize (gelati...

Embodiment 2

[0047] A method for preparing a magnetic carbon composite material for repairing heavy metal-contaminated soil, comprising the steps of:

[0048] S1. Preparation of modified raw materials:

[0049] S11. Preparation of magnetically modified biochar material: FeCl 2 • 4H 2 O and FeCl 3 •6H 2 Under the protection of nitrogen, O is mixed according to the molar ratio of 1:1 to form an iron salt mixture, and then add biochar and water to mix evenly, so that the biochar can absorb ferrous and ferric salts, and naturally filter out the liquid to obtain Adsorb the biochar of ferrous iron salt and ferric salt, then add dropwise ammonia water with a mass concentration of 25%, the reaction temperature is 70°C, and the reaction time is 3h; after washing with water, a magnetically modified biochar material is obtained;

[0050] S12. Preparation of β-cyclodextrin modified starch: add β-cyclodextrin and tapioca starch into water to make a suspension, heat up and stir for gelatinization (g...

Embodiment 3

[0056] A method for preparing a magnetic carbon composite material for repairing heavy metal-contaminated soil, comprising the steps of:

[0057] S1. Preparation of modified raw materials:

[0058] S11. Preparation of magnetically modified biochar material: FeCl 2 • 4H 2 O and FeCl 3 •6H 2 Under the protection of nitrogen, O is mixed according to the molar ratio of 1.1:1 to form a mixture of iron salts, and then add biochar and water to mix evenly, so that the biochar can absorb ferrous salts and ferric salts, and naturally filter out the liquid. Obtain biochar that adsorbs ferrous salts and ferric salts, then add ammonia water with a mass concentration of 25% dropwise, the reaction temperature is 60°C, and the reaction time is 2h; after washing with water, a magnetically modified biochar material is obtained;

[0059] S12. Preparation of β-cyclodextrin modified starch: add β-cyclodextrin and tapioca starch into water to make a suspension, heat up and stir to gelatinize (g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com