Magnetic coagulating sedimentation treatment device for pharmaceutical wastewater and treatment process thereof

A technology for sedimentation treatment and pharmaceutical wastewater, applied in flocculation/sedimentation water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as ineffective removal, damage to mixer blades, high safety requirements, etc., to achieve Avoid damage to mixer blades, avoid risk of wear, reduce the effect of pollutant concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

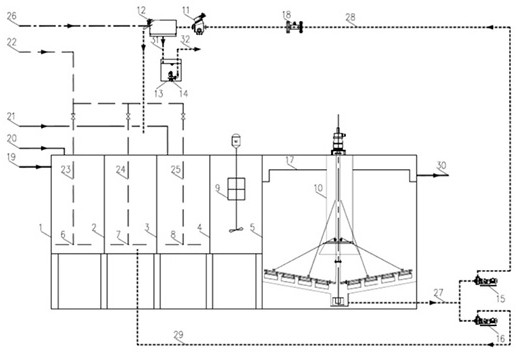

[0042] For an enterprise that produces organic chemical raw materials such as antihypertensive drugs, antirheumatic drugs, cardiovascular and cerebrovascular drugs, antineoplastic drugs, and antibacterial drugs, the production wastewater is divided into high-concentration wastewater and low-concentration wastewater. CODcr 180000mg / L, NH 3 -N 10400mg / L, TN 15600mg / L, SS 100mg / L, TDS 78000mg / L. The high-concentration wastewater is treated by a sewage treatment process using the magnetic coagulation sedimentation treatment device of the present invention.

[0043] The sewage passes through the first fast mixing tank, the second fast mixing tank, the third fast mixing tank, the flocculation reaction tank, and the clarification sedimentation tank in turn, and the residence time is 2min, 5min, 2min, 10min, 60min in turn, and the first fast mixing tank is put into Add PAC, the dosage is 300mg / L, and the air stirring intensity is 3-6m 3 / m 2 .h; Add magnetic powder to the second fa...

Embodiment 2

[0051] For an enterprise that produces amphetamine, methocarbamol, tiapride hydrochloride, glichet and other drugs, the production wastewater is divided into high-concentration wastewater and low-concentration wastewater. CODcr 100000mg / L, NH in high concentration wastewater 3 -N 300mg / L, TN 500mg / L, SS200mg / L, TDS 150000mg / L. The high-concentration wastewater is treated by a sewage treatment process using the magnetic coagulation sedimentation treatment device of the present invention.

[0052] Sewage passes through the first fast mixing tank, the second fast mixing tank, the third fast mixing tank, the flocculation reaction tank, and the clarification sedimentation tank in turn, and the residence time is 1min, 3min, 1min, 15min, 45min, in which the first fast mixing tank Add PAC, the dosage is 500mg / L, and the air stirring intensity is 3-6m 3 / m 2 .h; Add magnetic powder to the second fast mixing tank, the dosage is 30mg / L, and the air stirring intensity is 5-8m 3 / m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com