Treatment method of high-water-content oil sludge

A treatment method and technology for water-containing oil, which can be used in water/sludge/sewage treatment, sludge treatment, immiscible solvent sludge treatment, etc., and can solve the problems of complex composition, large area occupied by microbial methods, and limited treatment. , to achieve the effect of good drying effect, abandoning re-pollution and significant resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

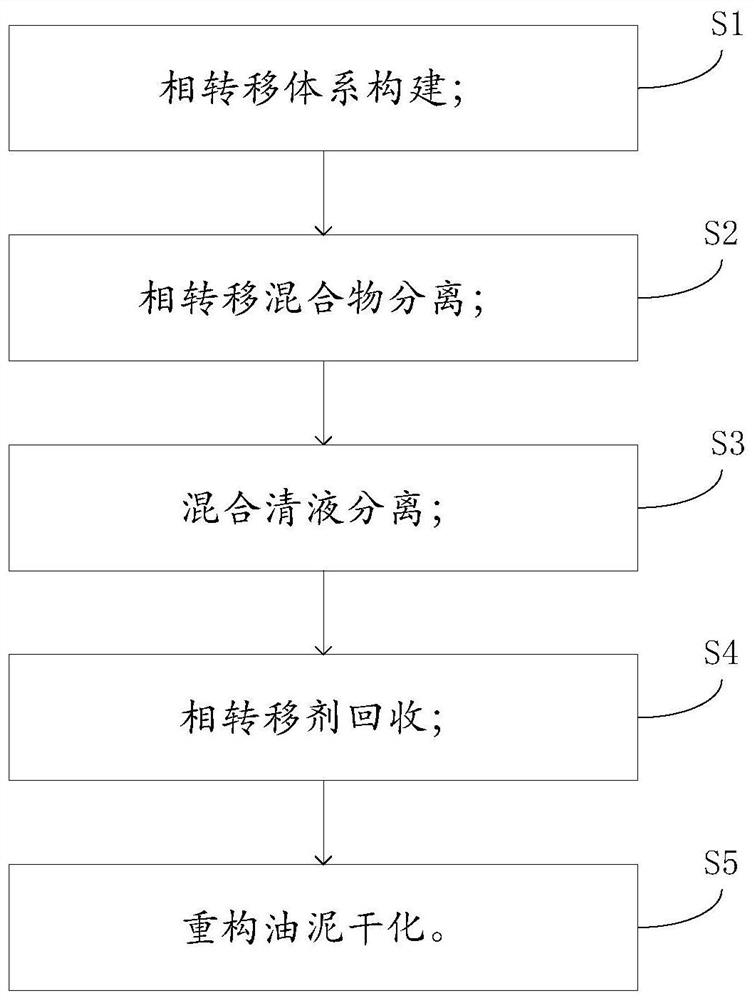

Method used

Image

Examples

Embodiment 1

[0036] The sample treated in this example is a high water content oil sludge (water content 88.74%, oil content 7.79%, solid content 3.47%) of a petrochemical plant in Lanzhou, and the phase transfer agent is (by weight): diethylene glycol dimethyl Ether 80%, mixed xylene 20%, propylene glycol polyether 1.5% and p-phenylenediamine 0.5%.

[0037] In this example S1, 300 g of the above-mentioned high-water-content sludge and 150 g of special phase transfer agent were weighed and added to a 1000 ml open container, the temperature was raised to 50 ° C, put into a homogenizer and homogenized at a speed of 5000 rpm for 5 minutes to obtain a phase transfer mixture;

[0038] In this example S2, 450 g of the phase transfer mixture containing the phase transfer agent prepared in S1 was centrifuged at room temperature to obtain 264.4 g of oil, water, and agent mixed supernatant and 183.2 g of reconstituted sludge.

[0039] In this example S3, the mixed clear liquid obtained in S2 was lef...

Embodiment 2

[0044] The sample treated in this example is a high water content oil sludge (water content 68.58%, oil content 16.81%, solid content 14.61%) of a petrochemical plant in Jiujiang, and the phase transfer agent is (by weight): diethylene glycol dimethyl Ether 70%, mixed xylene 30%, propylene glycol polyether 0.5% and p-phenylenediamine 0.5%.

[0045] In this example S1, 300 g of the above-mentioned high water content sludge and 150 g of special phase transfer agent were weighed and added into a 1000 ml open container, and placed in a homogenizer at room temperature to homogenize for 5 minutes at a rotation speed of 5000 rpm to obtain a phase transfer mixture;

[0046] In this example S2, 450 g of the phase transfer mixture containing the phase transfer agent prepared in S1 was centrifuged at room temperature to obtain 229 g of oil, water, and agent mixed supernatant and 217.5 g of reconstituted sludge.

[0047] In this example S3, the mixed clear liquid obtained in S2 was heated...

Embodiment 3

[0052] The sample treated in this example is a high water content oil sludge (water content 88.74%, oil content 7.79%, solid content 3.47%) of a petrochemical plant in Lanzhou, and the phase transfer agent is (by weight): diethylene glycol dimethyl Ether 60%, mixed xylene 40%, propylene glycol polyether 1.5% and p-phenylenediamine 0.5%.

[0053] In this example S1, 300 g of the above-mentioned high-water-content sludge and 150 g of special phase transfer agent were weighed and added to a 1000 ml open container, the temperature was raised to 50 ° C, put into a homogenizer and homogenized at a speed of 5000 rpm for 5 minutes to obtain a phase transfer mixture;

[0054] In this example S2, 450 g of the phase transfer mixture containing the phase transfer agent prepared in S1 was centrifuged at room temperature to obtain 262.4 g of oil, water, and agent mixed supernatant and 184.2 g of reconstituted sludge.

[0055] In this example S3, the mixed clear liquid obtained in S2 was lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com