Quaternary ammonium salt cationic antibacterial and antifouling coating layer as well as preparation method and application thereof

A quaternary ammonium salt cation, antifouling coating technology, applied in antifouling/underwater coatings, coatings, polyether coatings, etc., can solve problems such as limited application, achieve excellent bacteriostatic effect, good cytocompatibility , the effect of inhibiting the initial contact of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0047] Raw materials used in Examples 1 to 3 of the present invention and their consumption are shown in Table 1 below:

[0048] Table 1

[0049]

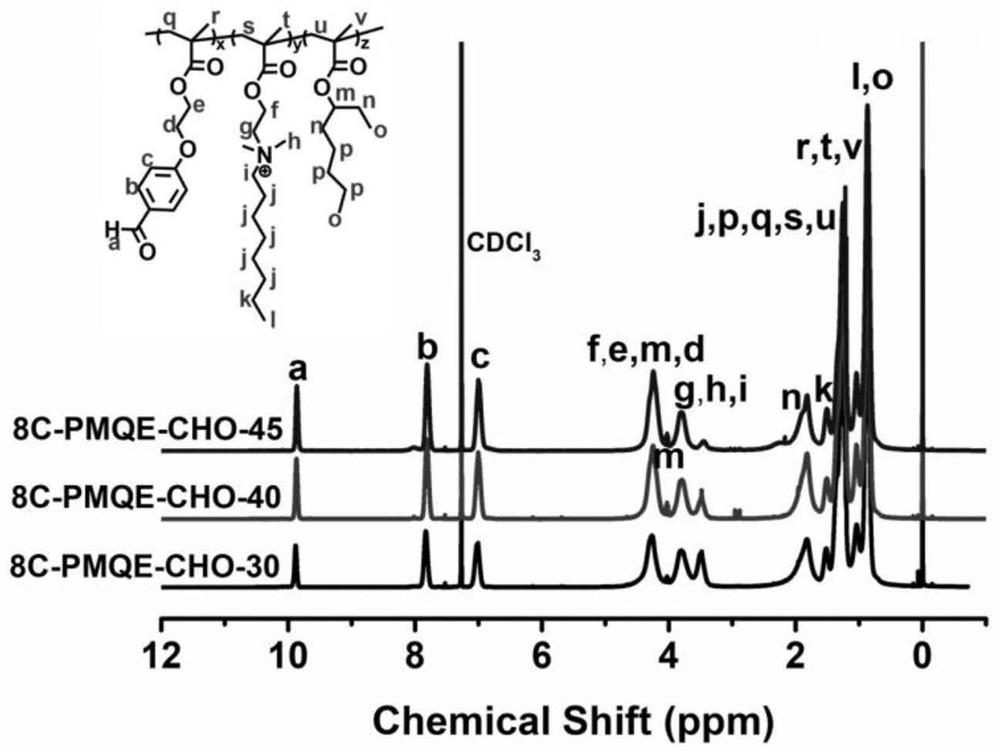

[0050] In a 100mL round bottom flask, according to the proportion shown in Table 1, add solvent DMF, initiator AIBN, monomer MAEBA, monomer QA8C, monomer EHA successively, pass N 2 After deoxygenation, it was vacuum-sealed and placed in an oil bath at 65°C for 24 hours with magnetic stirring. After the reaction was completed, it was cooled to room temperature, and anhydrous diethyl ether was used as a precipitating agent, and the purification was repeated 3 times. Finally vacuum-dry to constant weight, obtain the quaternary ammonium salt cationic polymer of embodiment 1~3, denote respectively as 8C-PMQE-CHO-30, 8C-PMQE-CHO-40, 8C-PMQE-CHO-45. Such as figure 1 Shown is the quaternary ammonium salt cationic polymer 8C-PMQE-CHO-30, 8C-PMQE-CHO-40, 8C-PMQE-CHO-45 of embodiment 1~3 1 In the H NMR spectrogram, in the figure, the h...

Embodiment 4

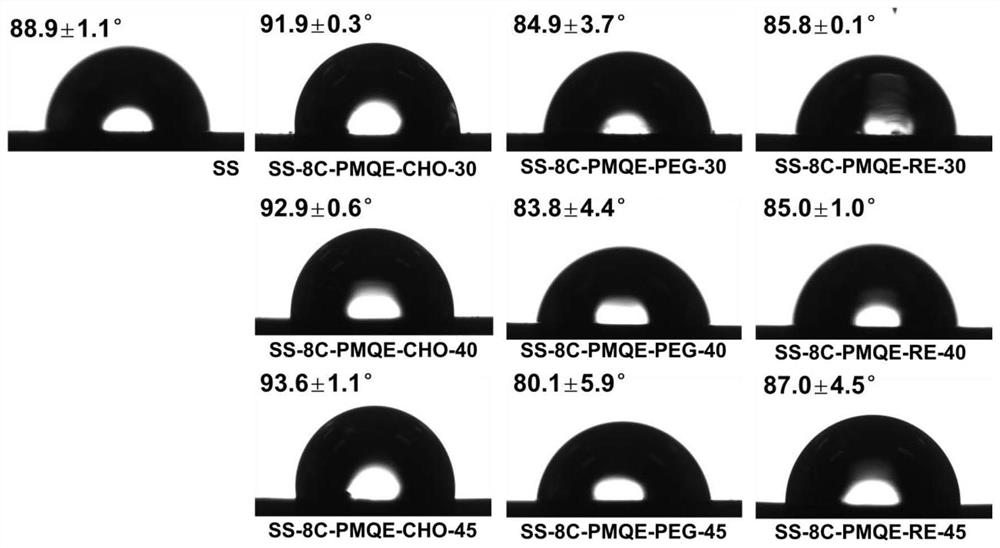

[0052] Preparation of quaternary ammonium salt cationic antibacterial and antifouling coating sample SS-8C-PMQE-PEG-30 and its Schiff base fracture coating sample SS-8C-PMQE on the surface of medical stainless steel 316L substrate (SS) by dip coating -RE-30, the specific preparation steps are as follows:

[0053] Dissolve the quaternary ammonium salt cationic polymer 8C-PMQE-CHO-30 prepared in Example 1 in the solvent dichloromethane, and mix uniformly to obtain a 5 mg / mL coating solution for use; then use 400 mesh and 1000 Purpose: Grind the oxide layer on the surface of medical stainless steel 316L base material (SS) with sandpaper, wash and dry the surface with acetone and ethanol, soak in the above coating solution for 1min, take it out and dry it at room temperature, and repeat the soaking and drying three times to obtain the quaternary ammonium salt cationic polymer coating sample SS-8C-PMQE-CHO-30;

[0054] The above-mentioned quaternary ammonium salt cationic polymer ...

Embodiment 5

[0057] Preparation of quaternary ammonium salt cationic antibacterial and antifouling coating sample SS-8C-PMQE-PEG-40 and its Schiff base fracture coating sample SS-8C-PMQE on the surface of medical stainless steel 316L substrate (SS) by dip coating -RE-40, its preparation steps are the same as embodiment 4, the difference is only: embodiment 5 adopts the quaternary ammonium salt cationic polymer 8C-PMQE-CHO-40 that the embodiment 2 makes to replace the quaternary ammonium salt that the embodiment 1 makes Ammonium salt cationic polymer 8C-PMQE-CHO-30 participated in the reaction to obtain quaternary ammonium salt cationic polymer coating sample SS-8C-PMQE-CHO-40, and then obtained quaternary ammonium salt cationic antibacterial and antifouling coating sample SS-8C - PMQE-PEG-40 coating sample and Schiff base fracture coating sample SS-8C-PMQE-RE-40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com