A kind of silica composite acrylic/epoxy water-based resin and preparation method thereof

A technology of compounding acrylic acid and silica, applied in coatings, anti-corrosion coatings, etc., can solve the problems of poor stability of compound emulsion/dispersion, difficult to obtain products that meet the needs, and the grafting reaction is not easy to occur, and achieves smooth gloss. Affecting, hardness-increasing, dispersion-stabilizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

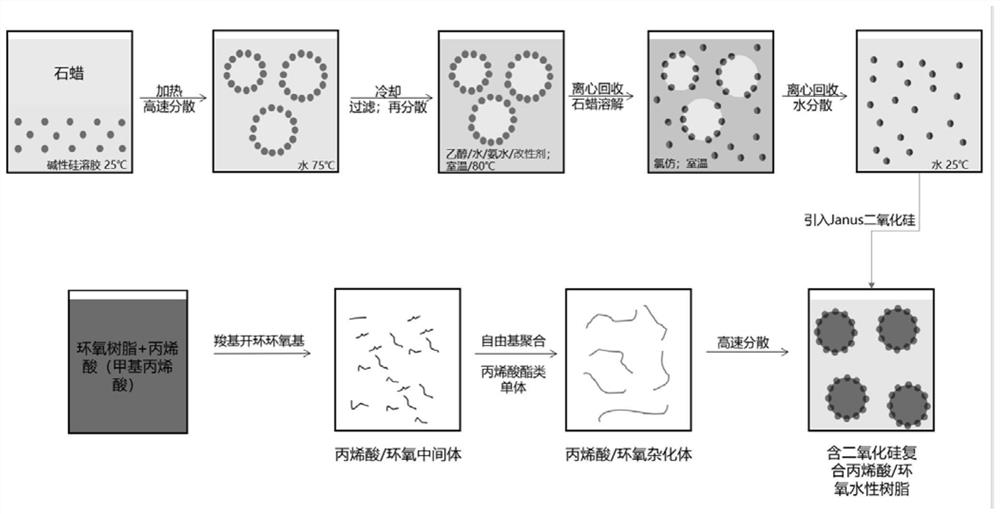

[0039]The preparation method of silica composite acrylic / epoxy resin comprises the following steps:

[0040] (1) Hybridizing epoxy resin and monomer to form acrylic / epoxy hybrid;

[0041] (2) preparing Janus-type silica particles containing alkyl groups on one side and unmodified on the other side, and then dispersing the Janus-type silica particles in deionized water to form a Janus-type silica particle aqueous dispersion;

[0042] (3) Adding the Janus-type silica particle aqueous dispersion prepared in step (2) into the acrylic / epoxy hybrid prepared in step (1) to form the silica composite acrylic / epoxy resin.

[0043] Step (1) includes the following steps:

[0044] ①Add 50g of epoxy resin to the container, raise the temperature to 100℃, then add 20g of solvent at 200rpm, then increase the speed to 400rpm and turn on nitrogen, and then dropwise add a mixture of 3g of methacrylic acid and 1g of initiator. The resulting mixed solution was added dropwise for 1 h, then heated ...

Embodiment 2

[0060] The preparation method of silica composite acrylic / epoxy resin comprises the following steps:

[0061] (1) Hybridizing epoxy resin and acrylate to form acrylic / epoxy hybrid;

[0062] (2) preparing Janus-type silica particles containing alkyl groups on one side and unmodified on the other side, and then dispersing the Janus-type silica particles in deionized water to form a Janus-type silica particle aqueous dispersion;

[0063] (3) Adding the Janus-type silica particle aqueous dispersion prepared in step (2) into the acrylic / epoxy hybrid prepared in step (1) to form the silica composite acrylic / epoxy resin.

[0064] Step (1) includes the following steps:

[0065] ①Add 70g of epoxy resin E44 to the container, heat up to 110℃, then add 40g of solvent at 150rpm, then increase the speed to 600rpm and turn on nitrogen, and then dropwise add 9g of methacrylic acid and 2g of initiator The mixed solution of the composition was added dropwise for 3h, then the temperature was r...

Embodiment 3

[0081] A preparation method of silica composite acrylic / epoxy water-based resin, comprising the following steps:

[0082] (1) Hybrid epoxy resin and monomer to form acrylic / epoxy hybrid:

[0083] Add 60g epoxy resin E44 to the second container, add 11g ethylene glycol butyl ether and 21.2g n-butanol after heating to 110°C, turn on nitrogen, and drip 6g methacrylic acid and 1.5g under the rotating speed of 500rpm. g benzoyl peroxide mixed solution, the dropping time was controlled at 2h, then the temperature was raised to 120°C and kept for 1h, and then 0.3g of benzoyl peroxide was added and kept at 120°C for 3h to obtain an acrylic acid / epoxy intermediate;

[0084] At a temperature of 110°C, 10g of butyl glycol ether and 20g of n-butanol were added to the third container while stirring, and then 4.8g of methacrylic acid, 35g of butyl acrylate, 13.6g of methacrylic acid, 35g of butyl acrylate, 13.6g of The mixture of methyl methacrylate, 15g acrylic acid / epoxy intermediate pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com