Supercritical carbon dioxide thermodynamic cycle power generation system and its control method

A carbon dioxide, supercritical technology, applied in machines/engines, steam engines, mechanical equipment, etc., can solve problems such as low thermal cycle efficiency, achieve high cycle efficiency, improve cycle thermal efficiency, and be environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

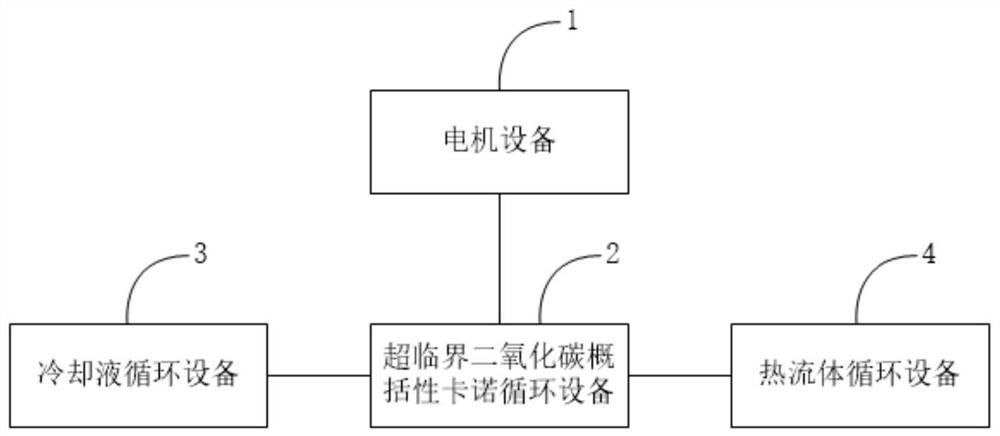

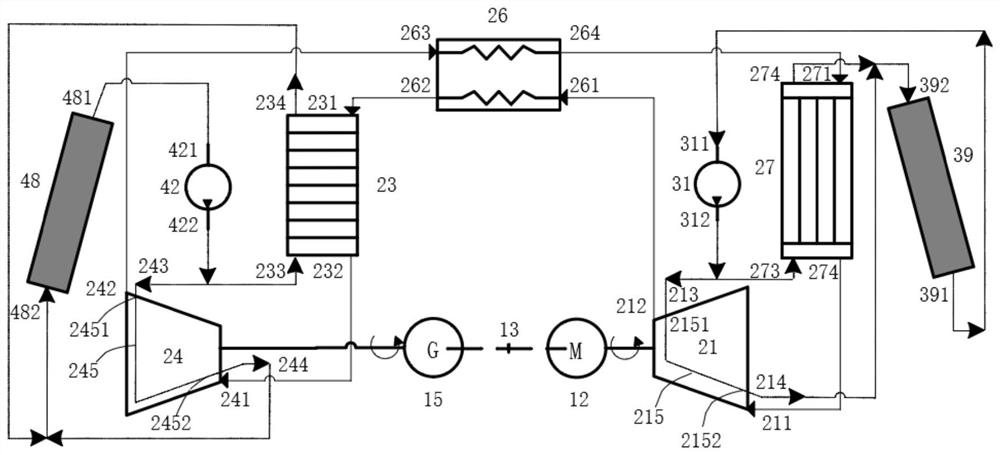

[0045] In order to solve the technical problem of low thermodynamic cycle efficiency in the prior art, an embodiment of the present invention provides a supercritical carbon dioxide thermodynamic cycle power generation system. Such as figure 2 As shown, it is a structural schematic diagram of an embodiment of the supercritical carbon dioxide thermodynamic cycle power generation system described in Embodiment 1 of the present disclosure. specific as figure 2 As shown, it includes motor equipment 1, supercritical carbon dioxide generalized Carnot cycle equipment 2, cooling liquid circulation equipment 3, and thermal fluid circulation equipment 4, wherein:

[0046] The motor device 1 includes a motor 12 and a generator 15 , and the generator 15 is connected to the rotating shaft of the motor 12 .

[0047] Preferably, the rotating shaft of the generator 15 and the motor 12 is connected through a coupling 13 .

[0048] Specifically, at the initial stage of start-up of the supe...

Embodiment 2

[0069] Based on the same inventive concept as that of Embodiment 1 of the present invention, Embodiment 2 of the present invention provides a control method for a supercritical carbon dioxide thermodynamic cycle power generation system, which can be applied to a supercritical carbon dioxide thermodynamic power generation system described in Embodiment 1. Cycle power generation system, the same content will not be repeated. Such as Figure 4 As shown, it is a schematic flow chart of the supercritical carbon dioxide thermodynamic cycle power generation control method provided in Embodiment 2 of the present invention. The specific control method includes the following steps:

[0070] Step 1101: Start the motor to drive the scroll compressor and scroll expander to rotate coaxially;

[0071] Step 1102: the scroll compressor performs isothermal compression on the supercritical carbon dioxide working medium;

[0072] Step 1103: The endothermic side of the regenerator receives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com