Flexible pressure sensor, preparation method and sensing system, flexible electronic skin

A technology of electronic skin and tactile sensor, which is applied in the field of flexible electronic skin and flexible pressure sensor. It can solve problems such as the difficult detection range of tiny pressure sensors, limited sensor application scenarios, and the complexity of high-sensitivity sensors, achieving small hysteresis and low price. Inexpensive, high initial sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

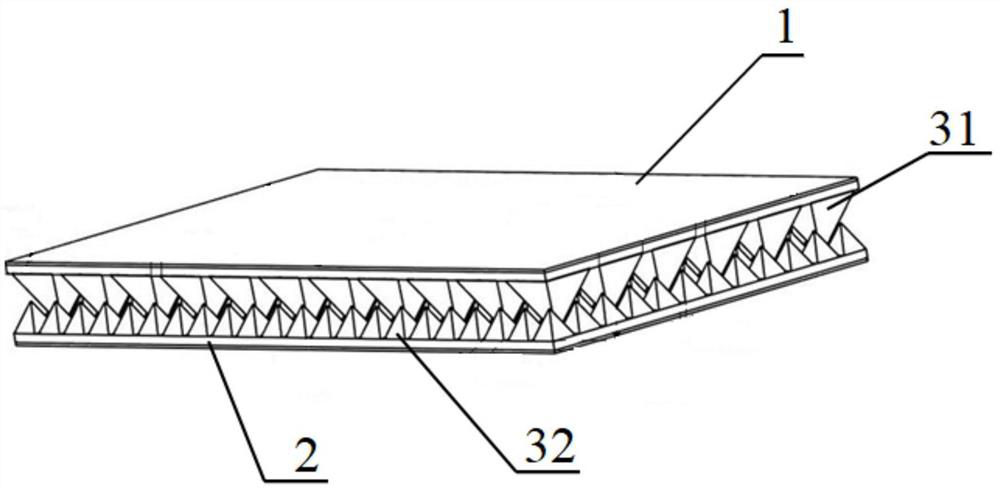

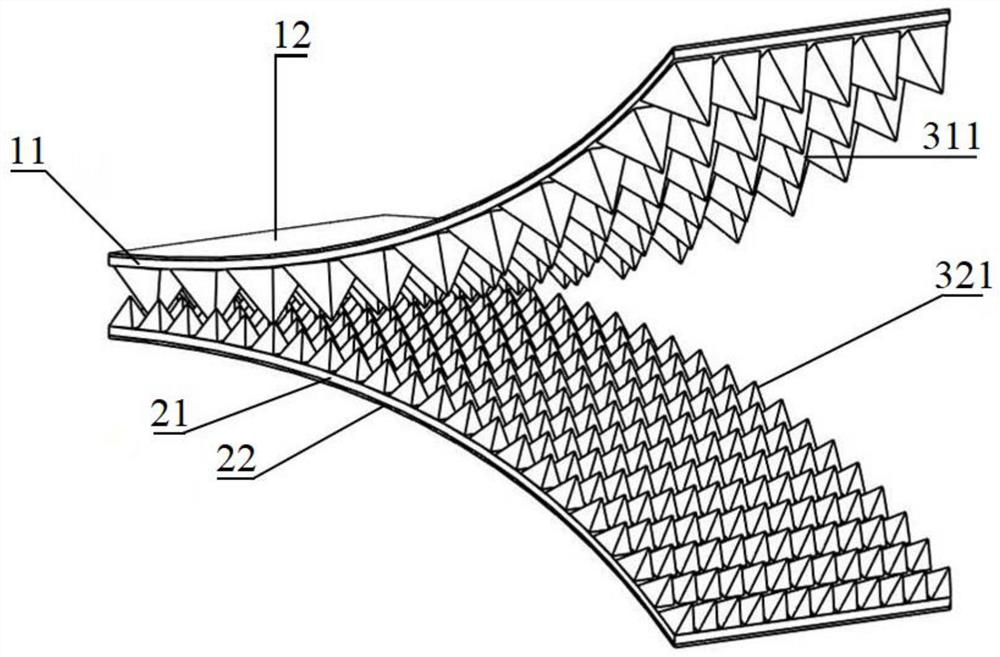

[0056] A preparation method according to the above-mentioned capacitive flexible pressure tactile sensor has the following steps: First, based on 3D printing technology and silicone rubber fluid molding technology, the three-dimensional CAD design software SolidWorks 2019 is used to model, and the first part used in the present invention is designed. A planar excitation electrode 11, a second planar excitation electrode 21, and the molds required for the first tip structure 311 and the second tip structure 321 of two types of sizes; after that, a composite material electrode of carbon nanotubes and copolyester is prepared, based on 3D Printing technology, print out the electrode mold, disperse the carbon nanotubes in isopropanol according to the weight ratio of 0.05wt%, pour an appropriate amount of copolyester prepolymerization solution, and inject it into the electrode mold, such as Figure 4 , after curing the copolyester prepolymerization solution containing carbon nanotube...

Embodiment 1

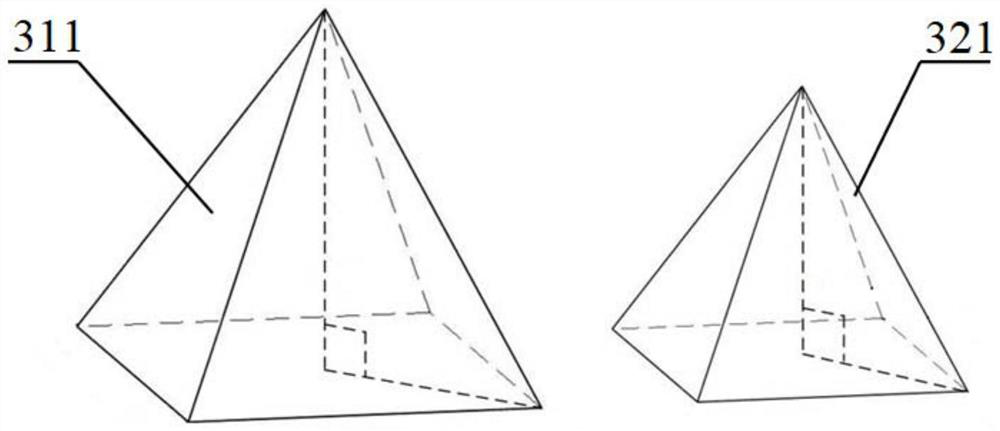

[0060] In this embodiment, according to the above-mentioned preparation method, a flexible pressure tactile sensor with the following dimensions is prepared. The first planar excitation electrode 11 and the second planar excitation electrode 21 have the same size and size, with a length of 13.1 mm and a width of 7.1 mm. The height is 0.15mm; the thickness of the first flexible substrate 11 and the second flexible substrate 12 is 0.04mm; the first tip structure 31 is in the shape of a large pyramid, and the length and width of the bottom of the large pyramid are 1mm and 1mm in height. 1mm, the second tip structure 32 is a small pyramid shape, the length and width of the small pyramid-shaped base are 0.5mm, and the height is 0.5mm; the first tip structures 31 are arranged and fixed according to the 0.4mm gap equidistant On the first planar excitation electrode 21, and the total width of the array extension dimension is 0.2 mm smaller than the width of the first planar excitation ...

Embodiment 2

[0062] The preparation method of the flexible pressure tactile sensor prepared in this example is the same as that in Example 1, except that the size of the prepared flexible pressure tactile sensor is different.

[0063] Specifically, the sensor of an embodiment of the present invention is based on the two-dimensional finite element simulation of COMSOL as follows: Figure 9 to Figure 16 A schematic diagram showing the simulation performance of an embodiment of the present invention, Figure 9Describes the two-dimensional simulation model diagram when the first tip structure 311 is in the shape of a large pyramid and the second tip structure 321 is in the shape of a small pyramid. It is mainly composed of three parts: the top shield layer, the electrode layer, and the dielectric layer. It is easy to converge for simulation , we connect the bottom of the pyramid to the thin layer, and form a dielectric layer as a whole, and scan the parameters of the height a of the large pyra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com