High-voltage composite positive electrode material and lithium ion battery containing same

A composite cathode material, lithium ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor thermal stability and safety performance, low energy density system, poor low temperature performance of lithium iron phosphate, etc. Good cycle performance and safety performance, improved charge cut-off voltage, and high volumetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

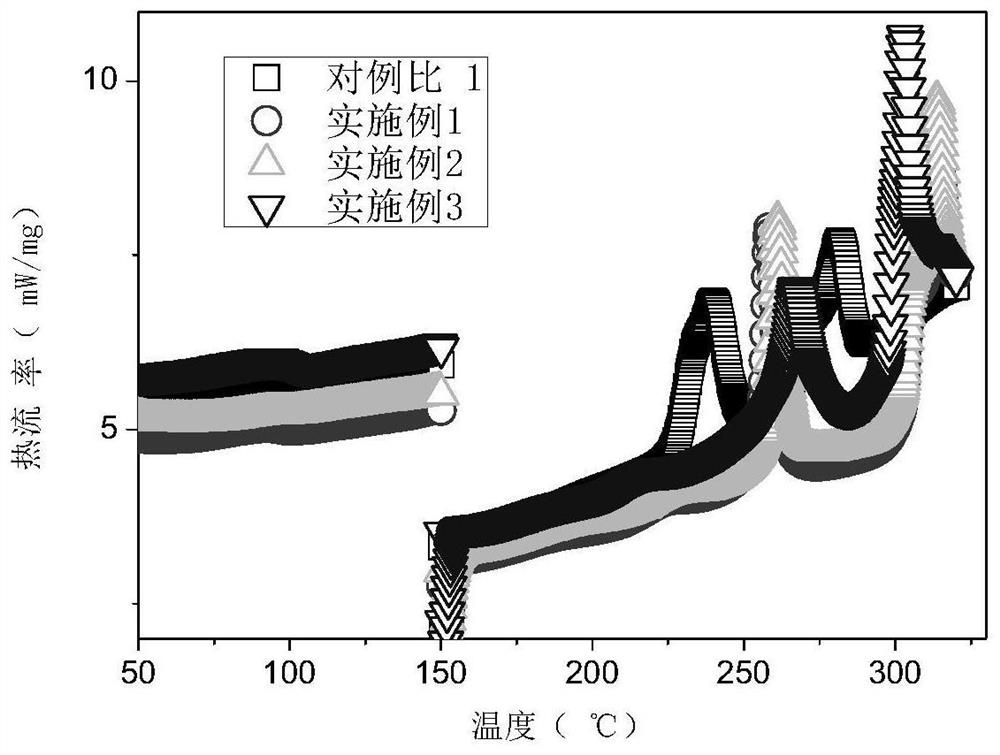

Embodiment 1

[0044] A composite positive electrode material for a high-voltage lithium-ion battery, comprising a base material C and a lithium zirconium phosphate fast ion conductor, the base material C is formed by mechanically and physically mixing material A and material B, and the mass ratio of material A to material B is 8 :2;

[0045] Among them, material A is Li 1.03 co 0.98 Ti 0.005 al 0.01 Y 0.005 o 2 , the morphology is single crystal particles, the median value D 50 is 17.5 μm, material A is prepared by gradation of particle size, and small particle D 50 4μm, large particle D 50 It is 18μm, and the mass ratio of size and particle is 8:2;

[0046] Among them, material B is Li 1.04 (Ni 0.5 co 0.2 mn 0.3 ) 0.99 Sr 0.005 al 0.005 o 2 , the morphology is single crystal particles, the median value D 50 5 μm;

[0047] The above matrix material C with 500ppm LiZr 2 (PO 4 ) 3 After physical mixing, put it in a muffle furnace, heat it to 650°C for 3 hours at a heating...

Embodiment 2

[0052] A composite positive electrode material for a high-voltage lithium-ion battery, comprising a base material C and a lithium zirconium phosphate fast ion conductor, the base material C is formed by mechanically and physically mixing material A and material B, and the mass ratio of material A to material B is 7 :3;

[0053] Among them, material A is Li 1.03 co 0.98 Ni 0.005 al 0.01 mn 0.005 o 2 , the morphology is single crystal particles, the median value D 50 is 17.5 μm, material A is prepared by gradation of particle size, and small particle D 50 4μm, large particle D 50 It is 18.5 μm, and the mass ratio of size and particle is 8:2;

[0054] Among them, material B is Li 1.04 (Ni 0.5 co 0.2 mn 0.3 ) 0.985 Sr 0.005 al 0.005 Y 0.005 o 2 , the morphology is single crystal particles, the median value D 50 5 μm;

[0055] The above matrix material C with 800ppm LiZr 2 (PO 4 ) 3 After physical mixing, put it in a muffle furnace, heat it to 650°C for 3 hour...

Embodiment 3

[0060] A composite positive electrode material for a high-voltage lithium-ion battery, comprising a base material C and a lithium zirconium phosphate fast ion conductor, the base material C is formed by mechanically and physically mixing material A and material B, and the mass ratio of material A to material B is 6 :4;

[0061] Among them, material A is Li 1.03 co 0.98 Mg 0.005 al 0.01 Ti 0.005 o 2 , the morphology is single crystal particles, the median value D 50 is 17.5 μm, material A is prepared by gradation of particle size, and small particle D 50 4μm, large particle D 50 18μm, the mass ratio of size and particle is 8:2;

[0062] Among them, material B is Li 1.04 (Ni 0.5 co 0.2 mn 0.3 ) 0.99 Sr 0.005 al 0.005 o 2 , the morphology is single crystal particles, the median value D 50 5 μm;

[0063] The above matrix material C with 1200ppm LiZr 2 (PO 4 ) 3 After physical mixing, put it in a muffle furnace, heat it to 650°C for 3 hours at a heating rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com