A sulfur autotrophic denitrification denitrification process

A treatment process, sulfur autotrophy technology, applied in anaerobic digestion treatment, special treatment targets, biological treatment devices, etc., can solve the problems of high energy consumption of reactors, low total nitrogen removal efficiency, and high alkalinity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

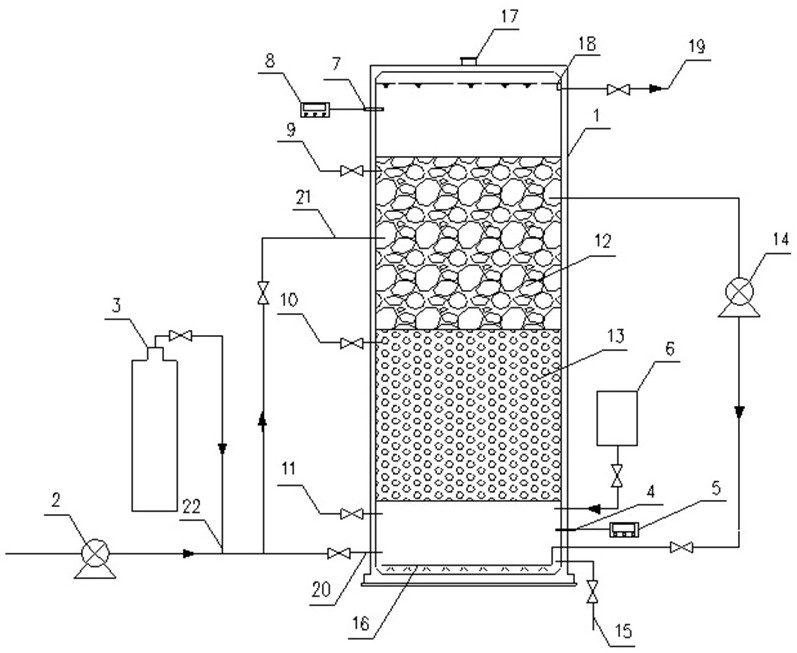

[0057] The amount of advanced wastewater treatment in a pharmaceutical wastewater treatment plant is about 3000m 3 / day, the quality of wastewater influent is COD 200-220mg / L, NH 3 -N 400-450mg / L, influent nitrate 150-200mg / L. The waste water is treated by adopting the sulfur autotrophic denitrification denitrification reaction device and its treatment process of the present invention.

[0058] The height-to-diameter ratio of the main reactor of the sulfur autotrophic denitrification reaction device is 6:1; the volume ratio of the influent mixing zone, sulfur autotrophic denitrification zone, anammox zone and effluent zone is 1:4: 6:2. In the acclimation stage, keep the pH of the influent at about 8, the temperature between 25°C and 35°C, the HRT at 6 hours, and the dissolved oxygen DO<0.3mg / L; The concentration of ammonia nitrogen in the water is 100-200mg / L, and the acclimation time is 2 days; the second stage, the concentration of nitrate in the influent is 100-150mg / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com