Cement containing large-proportion slag and preparation method of cement

A large-scale, cement-based technology that can be used in cement production, sustainable waste treatment, solid waste management, etc., to solve problems such as shortages, reduce corrosion, be affordable, and improve compressive and flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

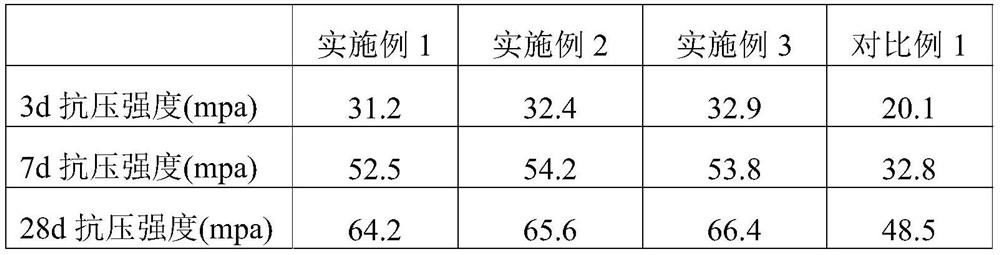

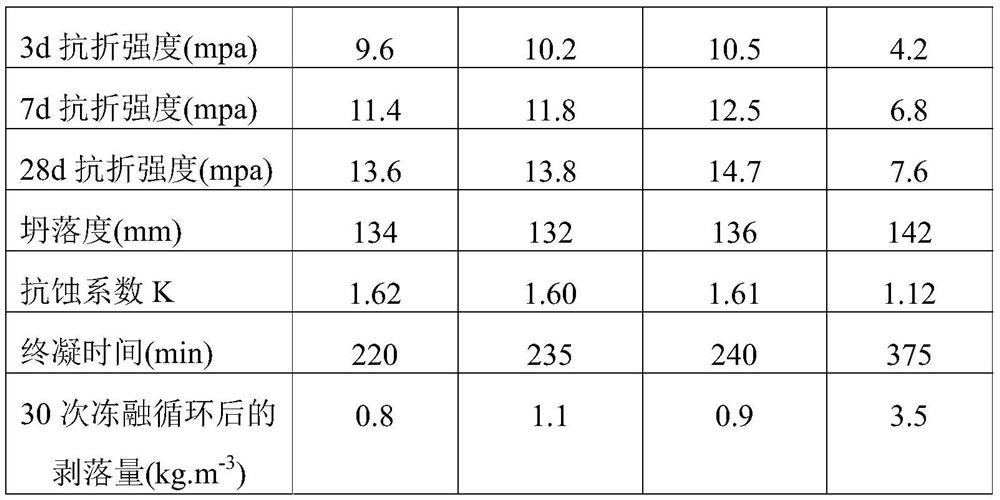

Examples

Embodiment 1

[0034] According to Table 1, the specific raw material is weighed, and the steps are prepared as follows:

[0035] (1) Dilution of triethanolamine is diluted by matching with triethanolamine, then sodium phosphate, industrial salt, and moisture is mixed, and the worn agent is obtained.

[0036] (2) Compare the silicate cement clinker, desulfurized gypsum, fly ash, aluminum sulfate, and aluminum sulfate, and the step (1), which are mixed, and then powder milling 30 min, and fine powder;

[0037] (3) According to the ratio, the sulfate, the potassium sulfate, the potassium sulfate, the potassium sulfate must be mixed, and the tetra-titanate can be mixed, and then the powder mill is 50 min, and the mix is mixed;

[0038] (4) The mixture obtained by the fine powder obtained from step (2) and the step (3) obtained, followed by bake at 50 ° C for 100 minutes in nitrogen protection environments to obtain cement.

Embodiment 2

[0040] (1) Dilution of triethanolamine is diluted by matching with triethanolamine, then sodium phosphate, industrial salt, and moisture is mixed, and the worn agent is obtained.

[0041] (2) Compare the silicate cement clinker, desulfurized gypsum, fly ash, aluminum sulfate, and step (1), and then mixed with powder milling for 40 min, and fine powder;

[0042] (3) According to the ratio, the slag, bases of magnesium sulfate, potassium sulfate, potassium sulfate, tetra-titanate, and tetra-titanate, followed by powder milling for 60 min, resulting in a total mixture;

[0043] (4) The mixture obtained by the fine powder obtained from step (2) and the step (3) obtained, followed by bakeing at 60 ° C for 90 minutes in the nitrogen protection environment to obtain cement.

Embodiment 3

[0045] (1) Dilution of triethanolamine is diluted by matching with triethanolamine, then sodium phosphate, industrial salt, and moisture is mixed, and the worn agent is obtained.

[0046] (2) Compare the silicate cement clinker, desulfurized gypsum, fly ash, aluminum sulfate, and step (1), and then mixed with powder milling for 40 min, and fine powder;

[0047] (3) According to the ratio, the slag, bases of magnesium sulfate, potassium sulfate, potassium sulfate, tetra-titanate, and tetra-titanate, followed by powder milling for 60 min, resulting in a total mixture;

[0048] (4) The mixture obtained by the fine powder obtained from step (2) and the step (3) obtained, then baked at 60 ° C for 100 minutes in nitrogen protection to obtain cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com