Preparation method of bazedoxifene

A technology of bazedoxifene and fixed bed, which is applied in the field of bazedoxifene preparation, can solve the problems of cumbersome filtration and recovery operations, great influence on the reaction conversion rate, long reaction time, etc., and achieve simple and easy operation of the process and simplified post-treatment Steps, reactions and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

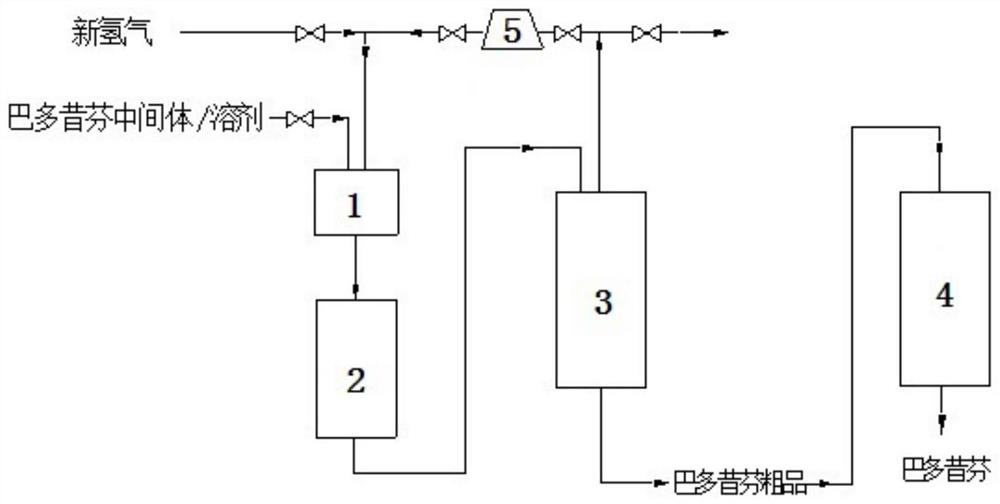

[0034] Such as figure 1 In the process flow shown, the bazedoxifene intermediate solution and hydrogen are first mixed in the mixer 1, and then the mixed material enters the fixed bed reactor 2 for catalytic hydrogenation reaction, and the reaction material enters the gas-liquid separator 3 after the reaction The liquid product is separated from the remaining hydrogen, and finally the liquid product enters the refining equipment 4 for refining to obtain the bazedoxifene refined product, while the remaining hydrogen is returned to the mixer 1 through the compressor 5 for recycling.

[0035] In the fixed-bed hydrogenation reaction device, the palladium / carbon catalyst is packed, the hydrogen pressure is adjusted to be 1.0MPa, and the feed rate of the solution of the bazedoxifene intermediate is 0.4ml / min, respectively at 20°C, 30°C, The reaction was performed at 40°C, 50°C, 60°C, and 70°C, and the HPLC results of each component of the hydrogenation reaction are shown in Table 1....

Embodiment 2

[0040] Such as figure 1 In the fixed-bed hydrogenation reaction device shown in the process, the palladium / carbon catalyst is packed, the reaction temperature is controlled at 65°C, the feed rate of the bazedoxifene intermediate solution is 0.4ml / min, and the hydrogen pressure is adjusted to 0.1MPa respectively , 0.4MPa, 0.7MPa, 1.0MPa, 1.2MPa, 1.5MPa, reaction under 1.8MPa, the HPLC results of each component of its hydrogenation reaction are shown in Table 2.

[0041] The investigation result of table 2 different hydrogen pressures

[0042] hydrogen pressure bazedoxifene Bazedoxifene intermediate Hydrogenation reaction intermediate 0.1MPa 88.7% 6.5% 4.8% 0.4MPa 93.4% 3.0% 3.6% 0.7MPa 98.0% 1.6% 1.4% 1.0MPa 98.3% 0.5% 1.2% 1.2 MPa 98.3% 0.4% 1.3% 1.5MPa 98.4% 0.5% 1.1% 1.8MPa 98.2% 0.4% 1.4%

[0043] It can be seen from Table 2 that in the preparation method of the present application, the hydrogen pr...

Embodiment 3

[0045] Such as figure 1 In the fixed-bed hydrogenation reaction device shown in the process, the palladium / carbon catalyst is packed, the reaction temperature is controlled at 65°C, and the hydrogen pressure is adjusted to 1.0MPa. The feed rate of the bazedoxifene intermediate solution is 0.1ml / min, 0.2 ml / min, 0.3ml / min, 0.4ml / min, 0.5ml / min, 0.6ml / min, and 0.7ml / min were reacted, and the HPLC results of each component of the hydrogenation reaction were shown in Table 3.

[0046] The investigation result of table 3 different feeding speeds

[0047]

[0048] It can be seen from Table 3 that in the preparation method of the present application, the feed rate of the reaction materials preferably ranges from 0.1 to 0.7 ml / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com