Nymphaea hybrid polysaccharide and preparation method thereof

A technology for perfume lotus and polysaccharide, which is applied in the directions of antitoxins, skin diseases, drug combinations, etc., can solve the problems of high extraction temperature, uneven color, low extraction efficiency, etc., and achieves the effects of good moisturizing, high purity, uniform and stable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 prepares macromolecule perfume lotus polysaccharide from perfume lotus:

[0037] (1) Perfume lotus is crushed and passed through a 40-mesh sieve, and 200 g of perfume lotus powder is weighed and placed in 600 mL of ethanol with a volume fraction of 90%, heated to reflux at 70 ° C for 3 h, filtered through filter paper, and the filter residue is dried in an oven at 40 ° C for 12 h. Get Perfume Lotus Powder.

[0038] (2) Accurately weigh 100g of perfume lotus powder, the mass ratio of perfume lotus powder to deionized water is 1:30, after 200W ultrasonication for 30min, heat and extract in a water bath at 70°C for 4h, the speed of the stirring paddle is 200rpm, after gauze filtration, Concentrate to 300mL under reduced pressure at 40°C with a rotary evaporator to obtain a concentrated perfume lotus crude polysaccharide extract.

[0039] (3) The AB-8 macroporous resin was soaked in deionized water for 6 hours, then soaked in ethanol with a volume fraction of ...

Embodiment 2

[0041]Embodiment 2 prepares the perfume lotus polysaccharide from the perfume lotus:

[0042] (1) Perfume lotus is crushed and passed through a 40-mesh sieve, weighed 200g of perfume lotus coarse powder and placed in 600mL of ethanol with a volume fraction of 90%, heated to reflux at 80°C for 3h, filtered through filter paper, and the filter residue was dried in an oven at 40°C for 12h. Get Perfume Lotus Powder.

[0043] (2) Accurately weigh 100g of perfume lotus powder, the mass ratio of perfume lotus powder to deionized water is 1:40, after 250W ultrasonication for 25min, heat and extract in a water bath at 80°C for 3h, the speed of the stirring paddle is 200rpm, after gauze filtration, Concentrate to 300mL under reduced pressure at 40°C with a rotary evaporator to obtain a concentrated perfume lotus crude polysaccharide extract.

[0044] (3) The AB-8 macroporous resin was soaked in deionized water for 6 hours, then soaked in ethanol with a volume fraction of 70% for 6 hour...

Embodiment 3

[0046] Embodiment 3 prepares the perfume lotus polysaccharide from the perfume lotus:

[0047] (1) Perfume lotus is crushed and passed through a 40-mesh sieve, and 400g of perfume lotus powder is weighed and placed in 1600mL of ethanol with a volume fraction of 90%, heated to reflux at 70°C for 3h, filtered through filter paper, and the filter residue is dried in an oven at 40°C for 10h. Get Perfume Lotus Powder.

[0048] (2) Accurately weigh 200g of perfume lotus flower powder, the mass ratio of perfume lotus flower powder to deionized water is 1:50, after 300W ultrasonication for 25min, heat and extract in a water bath at 70°C for 3h, the speed of the stirring paddle is 200rpm, after gauze filtration, Concentrate under reduced pressure at 60°C to 400mL in a rotary evaporator to obtain a concentrated extract of crude polysaccharide from lotus flower.

[0049] (3) The AB-8 macroporous resin was soaked in deionized water for 6 hours, then soaked in ethanol with a volume fracti...

PUM

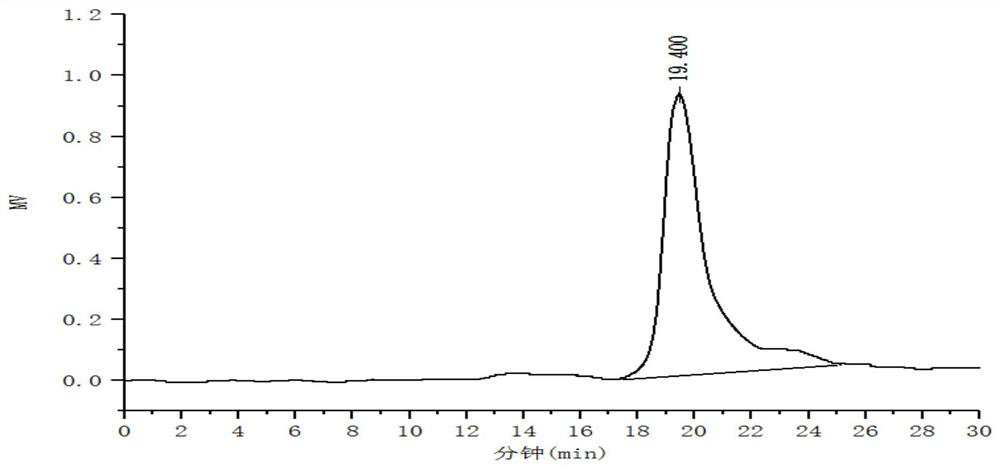

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com