A feeding method for lactating cows to increase the content of conjugated linoleic acid in milk

A technology for conjugated linoleic acid and lactating cows, applied in the field of animal husbandry, can solve problems such as limited conversion rate of conjugated linoleic acid, and achieve the effects of improving disease resistance, easy absorption, and increased milk production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

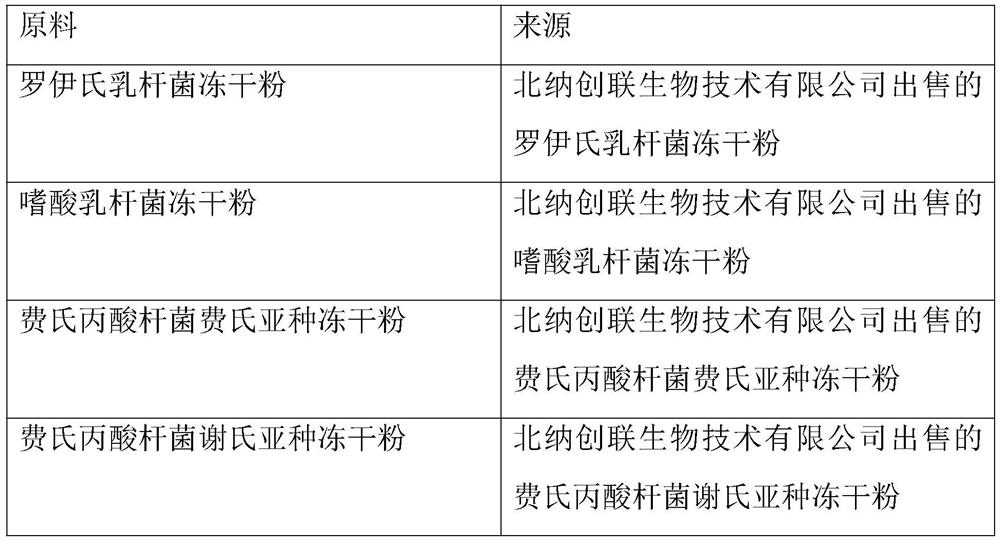

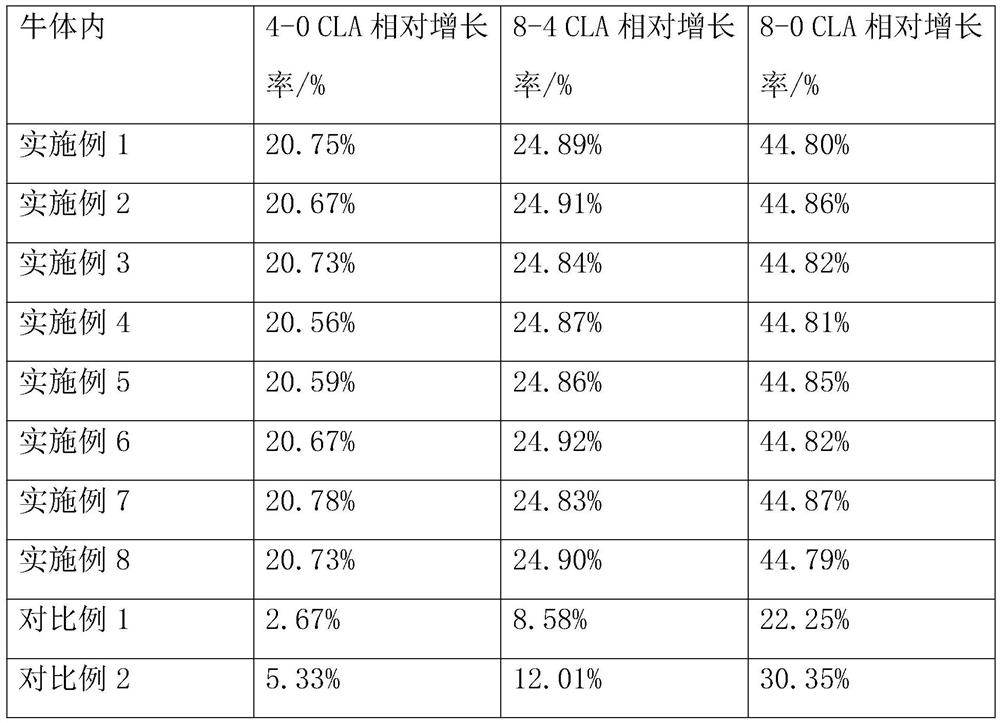

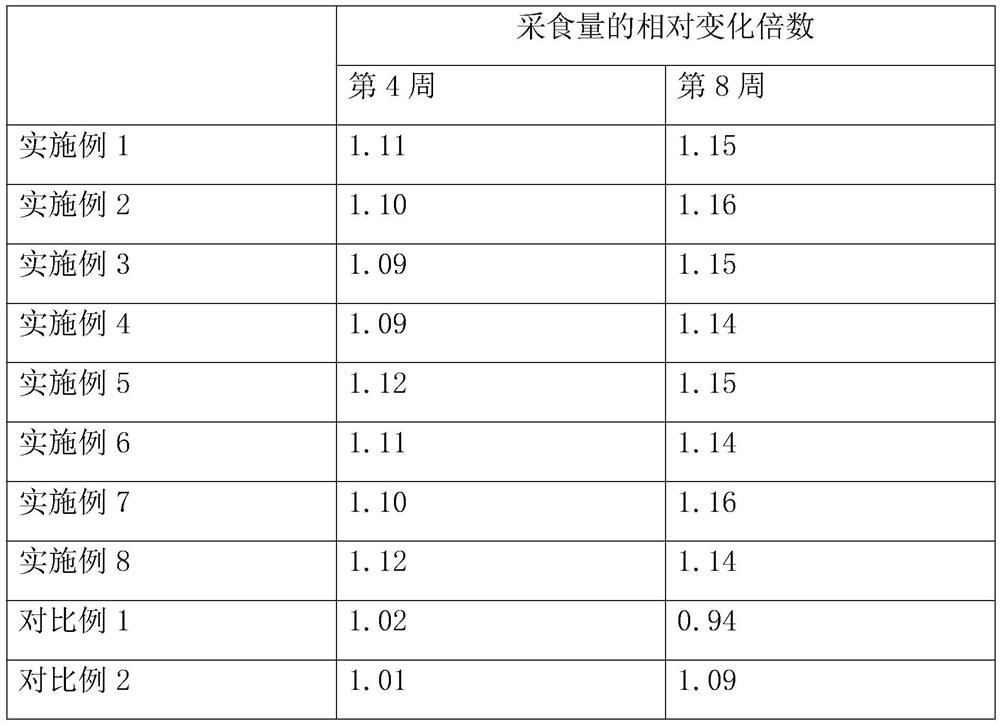

Method used

Image

Examples

Embodiment 1

[0049] This embodiment discloses a lactating cow feeding method for increasing the content of conjugated linoleic acid in milk, comprising the following steps:

[0050] Step 1, preparation of probiotic bacteria liquid:

[0051] Add Lactobacillus reuteri to MRS liquid medium, seal it, and culture it statically at 35°C, inoculate 1% of the bacteria, and cultivate it for 24 hours to obtain a bacterial concentration of 10 9 CFU / mL Lactobacillus reuteri bacteria liquid;

[0052] Add Lactobacillus acidophilus into the MRS liquid medium, seal it, and culture it statically at 35°C, with an inoculation amount of 1%, and cultivate it for 24 hours to obtain a bacterial concentration of 10 9 CFU / mL Lactobacillus acidophilus bacterial solution;

[0053] Add Propionibacterium frescheri subsp. Sherley into the MRS liquid medium, seal it, and culture it statically at 35°C. The inoculated amount is 1%, and cultivated for 48 hours to obtain a bacterial concentration of 10 9 CFU / mL of Propion...

Embodiment 2

[0061] The difference with embodiment 1 is:

[0062] In step 2-1, replace 1.5% rapeseed oil with 5% rapeseed.

[0063] In step 2-2, the total volume of Lactobacillus reuteri bacterium liquid, Lactobacillus acidophilus bacterium liquid, Propionibacterium frescherii subsp. The added volume ratio of each bacterial solution was 1:0.6:0.6:0.6.

Embodiment 3

[0065] The difference with embodiment 1 is:

[0066] Step 1, prepare probiotic freeze-dried powder: prepare active lactic acid bacteria content of 10 10 CFU / g of Lactobacillus reuteri lyophilized powder, Lactobacillus acidophilus lyophilized powder, Propionibacterium frescherii subsp.

[0067] In step 2-1, replace 1.5% rapeseed oil with 1% soybean oil.

[0068] In step 2-2, add the freeze-dried powder of Lactobacillus reuteri, the freeze-dried powder of Lactobacillus acidophilus, the freeze-dried powder of Propionibacterium frescherii subsp. For freeze-dried powder, the mass ratio added is 1:0.9:0.9:0.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com