Dry powder adsorbent uniform-mixing distribution test device and method

A distribution test and adsorbent technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as high investment costs, complex systems, and non-involved dry powder adsorbent homogeneous distribution detection test technology and devices , to achieve the effect of convenient use, high safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

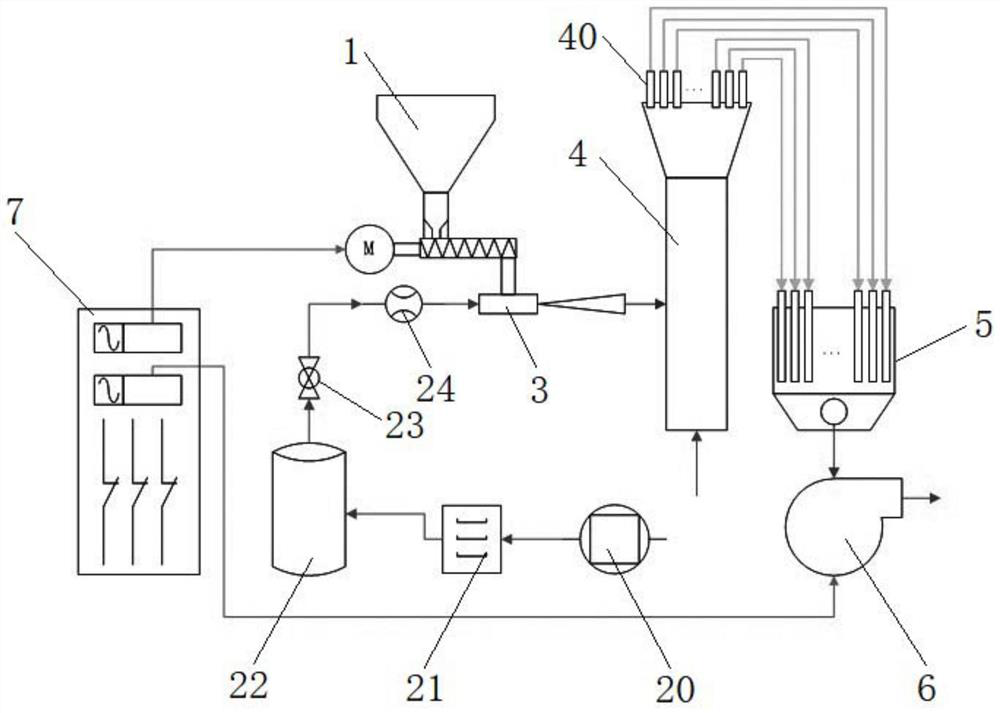

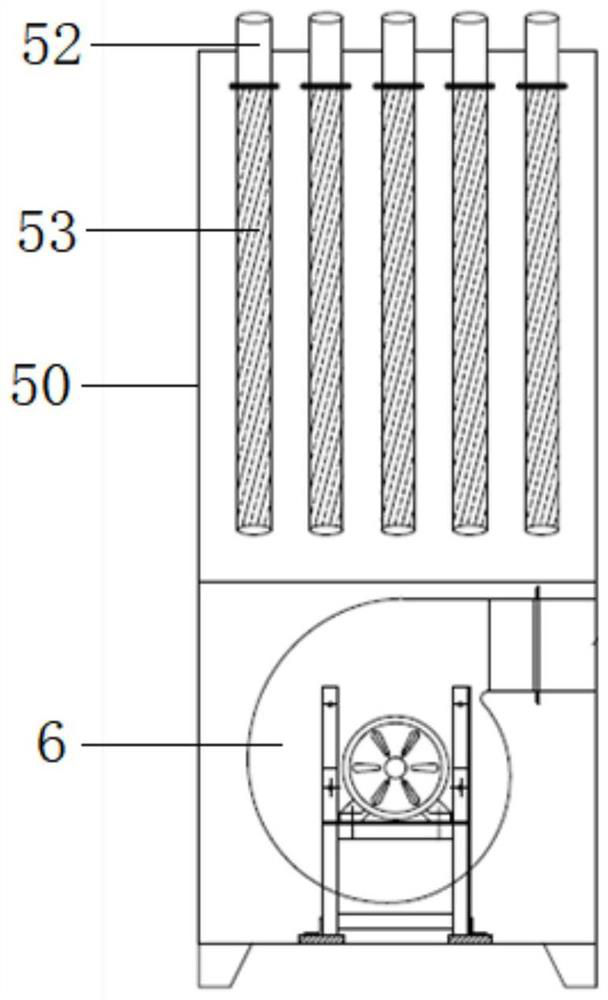

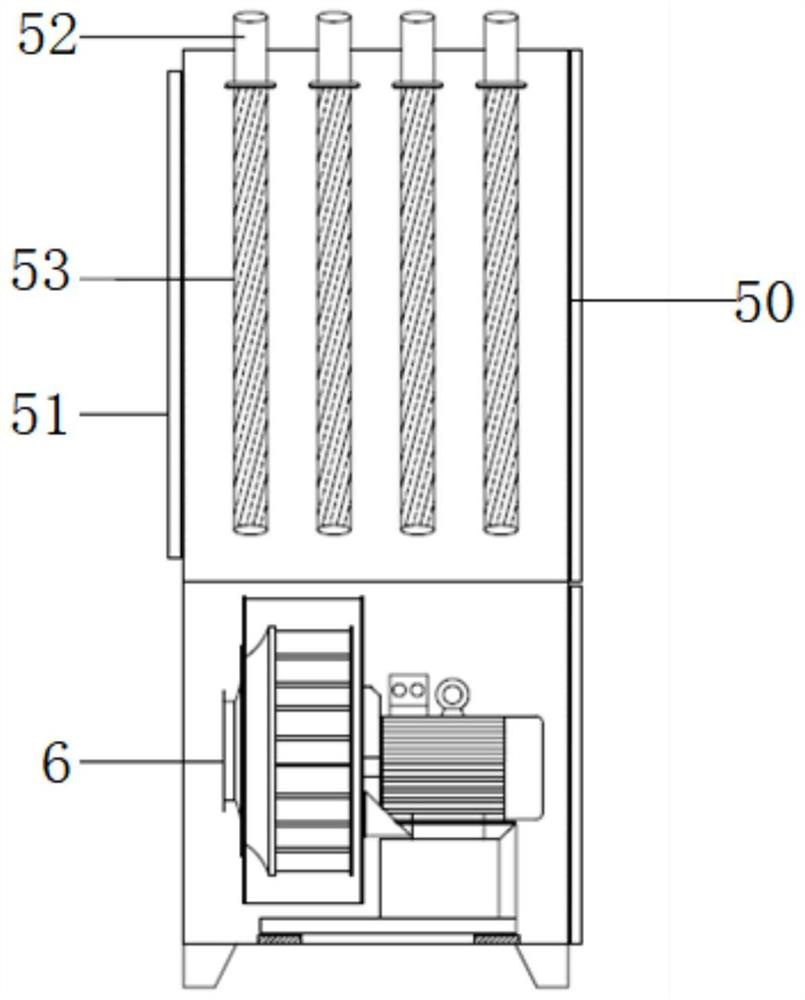

[0059] Such as figure 1 The shown dry powder adsorbent homogeneous distribution test system has been used for alkali dry powder spraying to remove SO 3 In the research and development of the device, calcium oxide dry powder with a particle size of about 325 mesh was used as the adsorbent in the test, and 20 air powder branch pipes were installed in the dry powder homogeneous distributor; the dust collector such as figure 2 , 3 As shown, 20 air powder inlet pipes and filter bags are set; the outer diameter of the air powder branch pipe and the air powder inlet pipe of the dust collector is consistent, both of which are 76mm; the inner diameter of the filter bag is consistent with the diameter of the air powder inlet pipe, and the length is 1200mm. The dust filtration efficiency of the dust with a diameter of 1 μm and above is ≥99%; the air velocity inside the dry powder homogeneous distributor is 7.5m / s, the feed rate of the adsorbent is 13.6kg / h, and the test time is 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com