High-power coupling concentration device

A concentration device and high-power technology, applied in the field of water treatment, to ensure the effect of accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

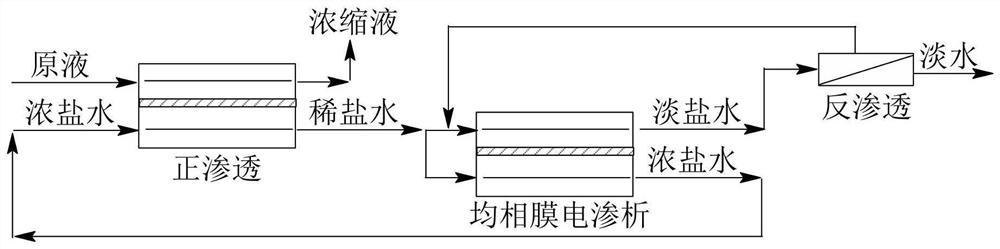

[0029]Appendfigure 1The structure shown, a high-magnifying concentrate, including a positive permeable component, a homogeneous membrane electrodialysis component, a reverse osmosis component, wherein the imported permeable component is connected to the stock output, and is divided into two exits after the positive infiltration member. All the way concentrate discharge system, the second plungeon salt export is invested with an incoming film electrodialysis component; the exit of the homogeneous membrane electrodialysis components is divided into two channels, the first stream of concentrated salt water exit and the import of positive permeable components, The exit of the secondary light salt and the inlet connection of reverse osmosis components; the export of reverse osmosis is divided into two channels, the first concentrated exit of the first circuit is connected to the import of the electrodalastic diaryllation parts, and the export of the second fresh water is discharged. use....

Embodiment 2

[0036]Similarly to Example 1, the positive permeation member is a hollow fiber positive permeable membrane prepared by poly acetate, and the diameter of the positive permeable hollow fibers is 0.8 mm, the interval is 99.5%, and the film flux is 1 liter / square meter. Hour . The concentration of the concentration of the concentration to be concentrated into the positive penetration was 2%, and the solution solution solution solution solution solution was 20%.

[0037]High-dimensional concentrated homogeneous membrane electrodialysis components use high-magnified electrodialysis apparatus electrodialysis apparatus. The ionic selectivity of the octopoelectric exchange membrane used 99.3%, the film resistance is 5 Eurome, and the sodium chloride solution can be concentrated to 20%, and the current efficiency can reach 90%.

[0038]The retention rate of the reverse osmosis component is 99.5%, and the film flux is 25 liters per square meter.

[0039]The concentration of 2% to be concentrated and ...

Embodiment 3

[0042]Similarly to Example 1, the positive permeation member is a hollow fiber positive permeable membrane prepared by poly acetate, and the diameter of the positive permeable hollow fibers is 1.5 mm, the retention rate is 99.5%, and the film flux is 3 liters per square meter. Hours . The concentration of concentration of concentration to be concentrated to be concentrated in positive penetration was 5%, and the concentration of a solution of a high solution sodium chloride solution was 20%.

[0043]High-dimensional concentrated homogeneous membrane electrodialysis components use high-magnified electrodialysis apparatus electrodialysis apparatus. The ionic selectivity of the yin and cation exchange membrane used 99.5%, the membrane resistance is 5 Eurome / square centimeter, and the sodium chloride solution can be concentrated to 20%, and the current efficiency can reach 95%.

[0044]The retention rate of the reverse osmosis component was 99.6%, and the film flux was 20 liters per square ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com