High-performance flame-retardant self-cleaning daylighting panel material easy to melt and break and free of dripping and production process thereof

A lighting board, high-performance technology, applied in the production of bulk chemicals, coating, etc., can solve the problems of low mechanical properties, easy dripping, and high material cost of lighting boards, and achieve increased stain resistance and aesthetics. The effect of uniform distribution and improvement of limiting oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A self-cleaning flame-retardant lighting board that is easy to melt and not drip, comprising the following components in mass percentage:

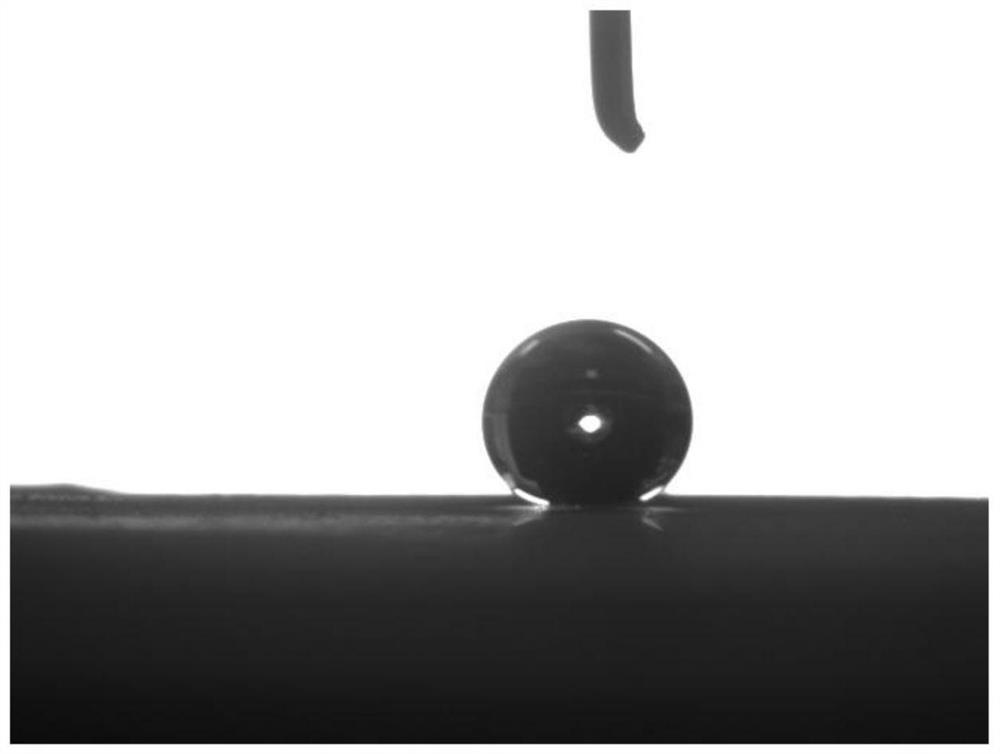

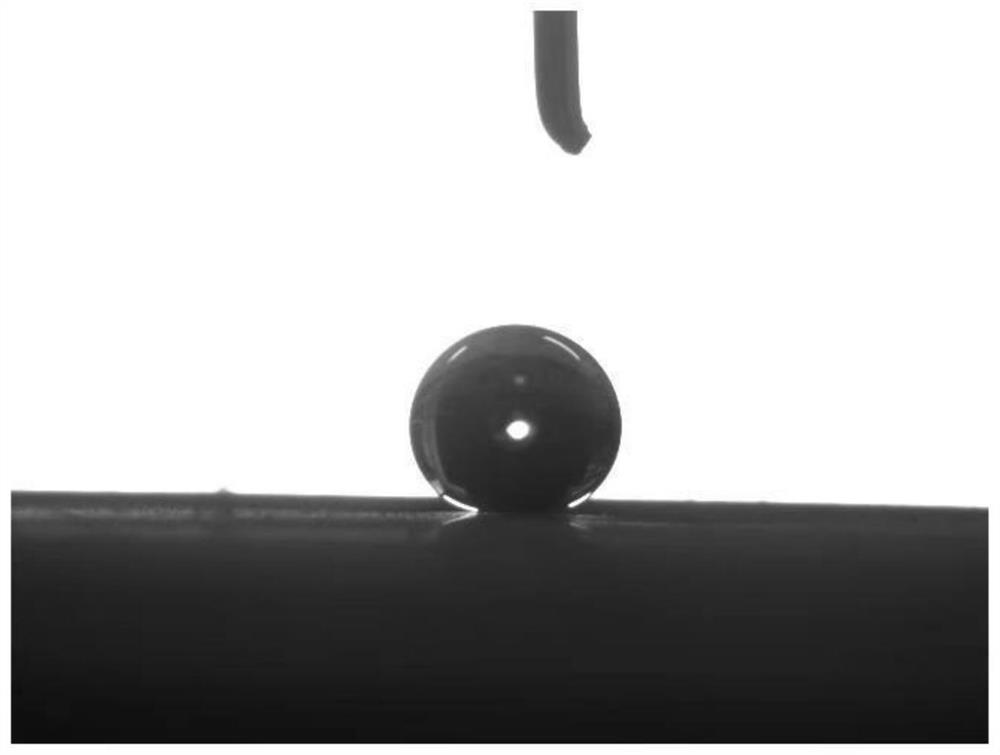

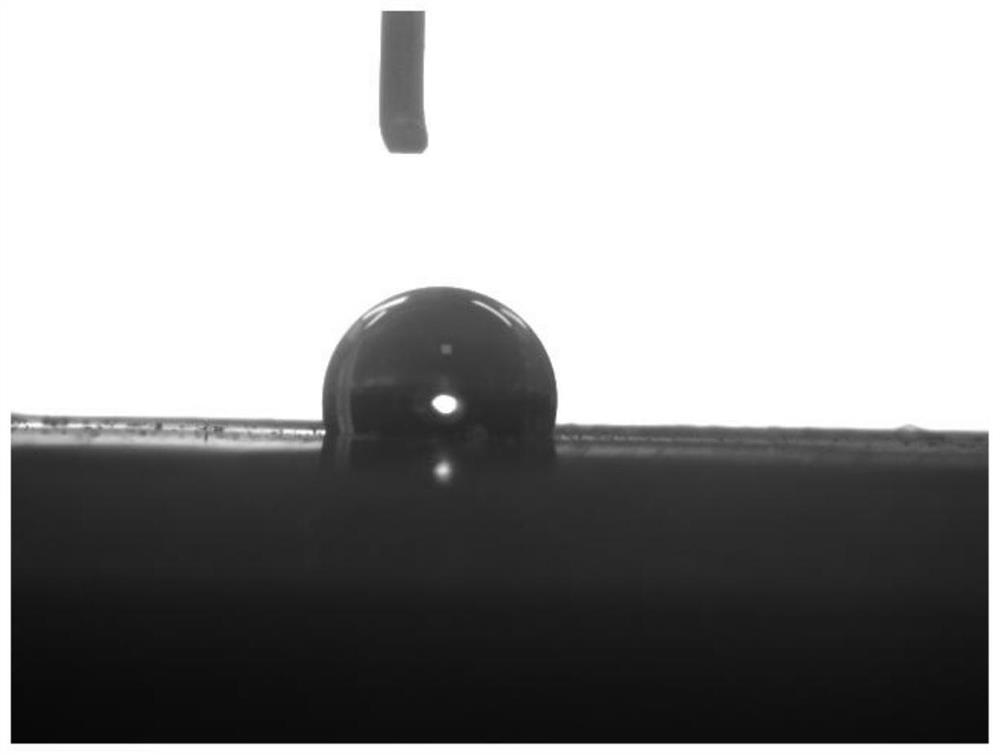

[0040] 30% low-density polyolefin, 20% polypropylene, 5% ethylene wax, 20% intumescent flame retardant (ammonium polyphosphate and triazine char-forming agent with a mass ratio of 1:1), 20% glass fiber, Malay Anhydride grafted polyethylene 3%, antioxidant 1618 0.5%, antioxidant 1010 0.5%, silicone powder 1%, wherein, the surface of the lighting board prepared by the above components is coated with a 0.8 μm transparent super-amphiphobic coating ,

[0041] Its production process includes the following steps:

[0042] Step 1. According to the above formula of a high-performance flame-retardant lighting board that is easy to melt and not drip, weigh each component and dry it for later use;

[0043] Step 2, mixing low-density polyolefin, polypropylene, ethylene wax, intumescent flame retardant, maleic anhydride grafted polyethylene, an...

Embodiment 2

[0050] A high-performance flame-retardant lighting board that is easy to melt and not drip, including the following components in mass percentage:

[0051] 20% low-density polyolefin, 20% polypropylene, 10% ethylene vinyl acetate copolymer, 5% ethylene wax, 20% intumescent flame retardant (ammonium polyphosphate and triazine char-forming agent with a mass ratio of 1:1) , glass fiber 20%, maleic anhydride grafted polyethylene 3%, antioxidant 1618 0.5%, antioxidant 1010 0.5%, silicone powder 1%, wherein, the surface of the lighting board prepared by the above components is coated with 0.8μm transparent superamphiphobic coating;

[0052] Its production technology is with embodiment 1.

Embodiment 3

[0054] A high-performance flame-retardant lighting board that is easy to melt and not drip, including the following components in mass percentage:

[0055] 25% low-density polyolefin, 15% polypropylene, 5% ethylene wax, 22% intumescent flame retardant (ammonium polyphosphate and triazine char-forming agent with a mass ratio of 1:1), 28% glass fiber, Malay Anhydride grafted polyethylene 3%, antioxidant 1618 0.5%, antioxidant 1010 0.5%, silicone powder 1%, wherein, the surface of the lighting board prepared by the above components is coated with a 0.8 μm transparent super-amphiphobic coating ;

[0056] Its production technology is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com