Continuous production method of lithium ion battery negative electrode coating material

A technology for lithium ion batteries and coating materials, which is applied in the field of continuous production of negative electrode coating materials for lithium ion batteries, can solve the problems of incapable of continuous production, switching between multiple reactors, complicated processes, etc., so as to achieve product industrialization and reduce Production cost, the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

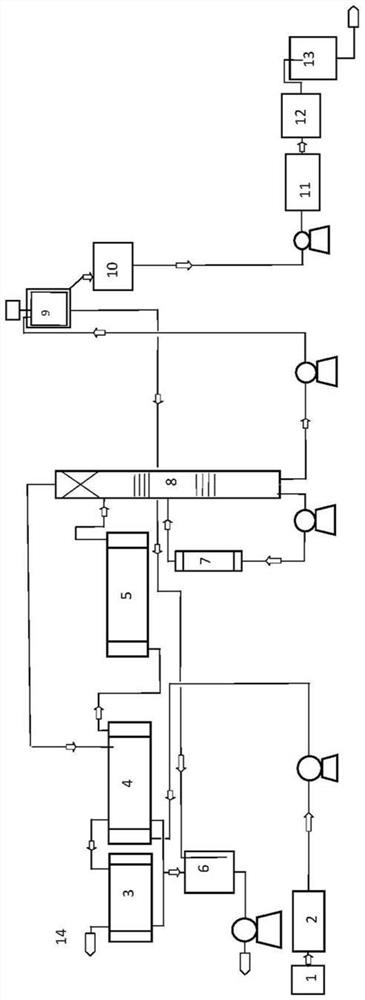

[0020] Embodiment 1: refer to figure 1 , is a schematic structural diagram of Embodiment 1 of the present invention,

[0021] A continuous production method for lithium-ion battery negative electrode coating materials, characterized in that it comprises the following steps:

[0022] (1) Raw material preheating: Preheat the raw material ethylene tar or ethylene residue in the raw material oil storage tank to 70-100°C, and use the delivery pump to transport the preheated raw material to the first-stage condensation preheater and the raw material oil preheater. Heater, the primary condensation preheater heats the raw material to 140-170°C, and the raw material oil preheater heats the raw material to 200-300°C;

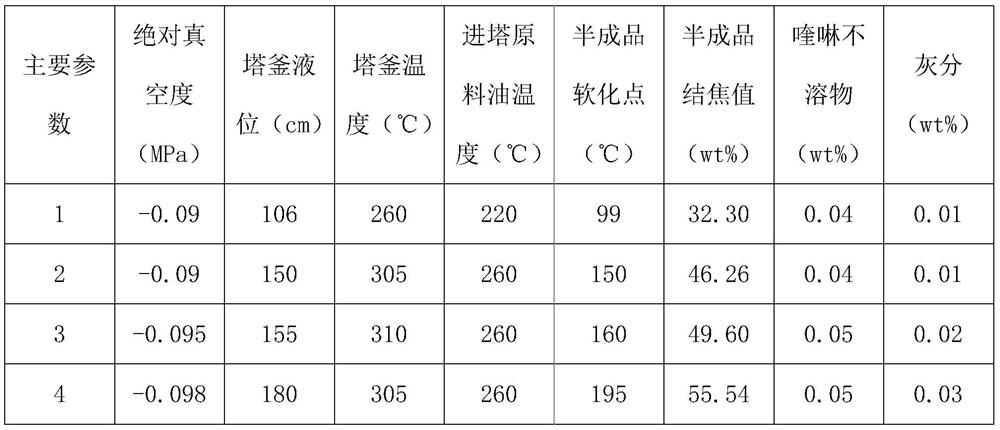

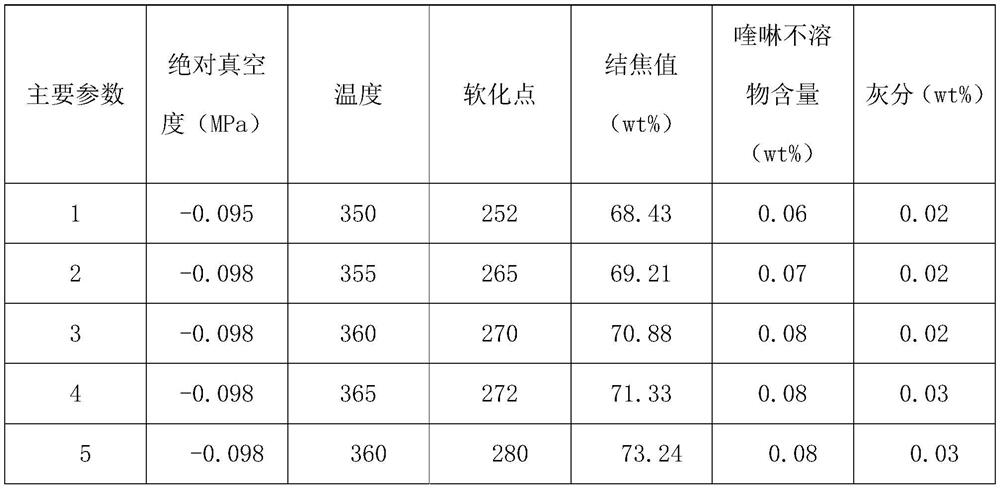

[0023] (2) Rectification: transport the preheated raw materials in step (1) to the rectification tower through the delivery pump, and carry out rectification treatment to obtain asphalt whose softening point is less than 200°C; the rectification time is between 8 and 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com