Biodegradation method of lignin

A biodegradation and lignin technology, applied in the use of microorganisms/enzymatic cellulose treatment, papermaking, textiles and papermaking, etc., can solve the problems of few researches on bacteria, and achieve the effect of easy operation, good degradation effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The biodegradation operation steps of a kind of lignin are as follows:

[0082] (1) Cultured strains

[0083] Raoultia ornithini Raoultella ornithinolytica Inoculate one loop of slant strains on LB solid medium, culture at 28°C for 24-72 hours to obtain activated strains;

[0084] (2) Preparation of bacterial suspension

[0085] Inoculate the activated strain on LB liquid medium with an inoculum size of 2%, and cultivate it on a shaker at a temperature of 28°C and 180r / min for 2 to 3 days to obtain a fermentation broth;

[0086] Take 2ml of fermentation broth and inoculate it into 100ml of LB liquid medium, culture on a shaker at 28°C and 180r / min for 2-3 days to obtain a bacterial suspension;

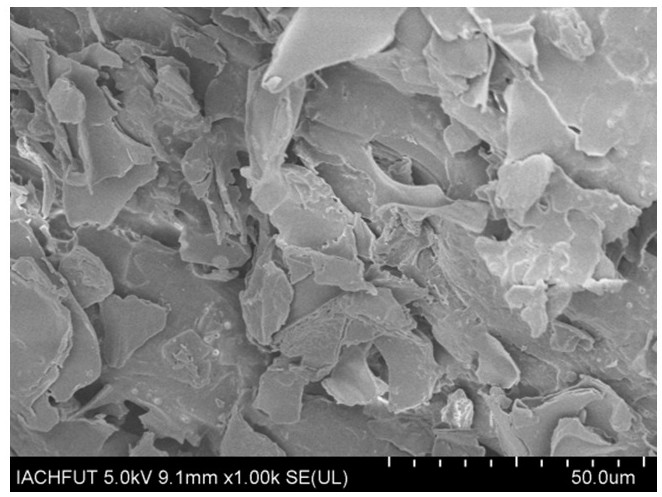

[0087] (3) Processing lignin materials

[0088] The lignin material in this embodiment is corn stalks;

[0089] drying the corn stalks at a temperature of 45°C, crushing them; sieving through a 30-40 mesh sieve, and drying at a temperature of 45°C again to obtain corn stalk...

Embodiment 2

[0094] The biodegradation operation steps of a kind of lignin are as follows:

[0095] (1) Cultured strains

[0096] Raoultia ornithini Raoultella ornithinolytica Inoculate one loop of slant strains on LB solid medium, culture at 28°C for 24-72 hours to obtain activated strains;

[0097] (2) Preparation of bacterial suspension

[0098] Inoculate the activated strain on LB liquid medium with an inoculum size of 2%, and cultivate it on a shaker at a temperature of 28°C and 180r / min for 2 to 3 days to obtain a fermentation broth;

[0099] Take 2ml of fermentation broth and inoculate it into 100ml of LB liquid medium, culture on a shaker at 28°C and 180r / min for 2-3 days to obtain a bacterial suspension;

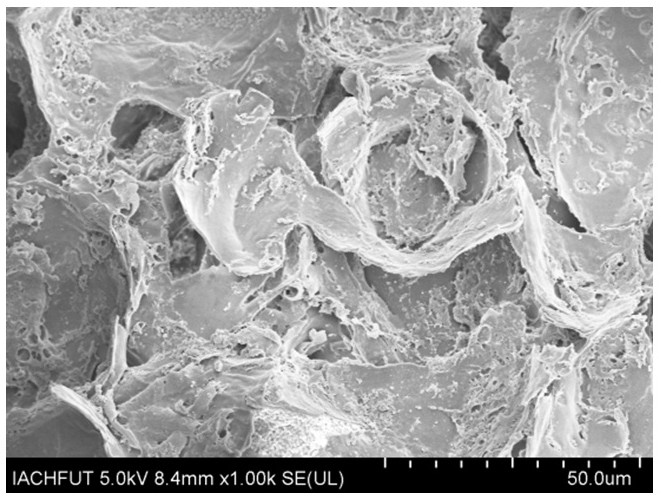

[0100] (3) Processing lignin materials

[0101] The lignin material of this embodiment is wheat straw;

[0102] Drying the wheat straw at a temperature of 45°C and pulverizing it; sieving through a 30-40 mesh sieve, and drying at a temperature of 45°C again to obtain wheat ...

Embodiment 3

[0107] The biodegradation operation steps of a kind of lignin are as follows:

[0108] (1) Cultured strains

[0109] Raoultia ornithini Raoultella ornithinolytica Inoculate one loop of slant strains on LB solid medium, culture at 28°C for 24-72 hours to obtain activated strains;

[0110] (2) Preparation of bacterial suspension

[0111] Inoculate the activated strain on LB liquid medium with an inoculum size of 2%, and cultivate it on a shaker at a temperature of 28°C and 180r / min for 2 to 3 days to obtain a fermentation broth;

[0112] Take 2ml of fermentation broth and inoculate it into 100ml of LB liquid medium, culture on a shaker at 28°C and 180r / min for 2-3 days to obtain a bacterial suspension;

[0113] (3) Processing lignin material

[0114] The lignin material of the present embodiment is apple branch;

[0115] Drying the apple branches at a temperature of 45°C, crushing them; sieving through a 30-40 mesh sieve, and drying at a temperature of 45°C again to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com