Quantitative detection method for volatile flavor substances in fermented grains

A quantitative detection method and technology for flavor substances, which are applied in the field of flavor analysis of fermented grains, can solve the problems of small adsorption capacity, competitive adsorption of flavor substances, easy saturation of extraction heads, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

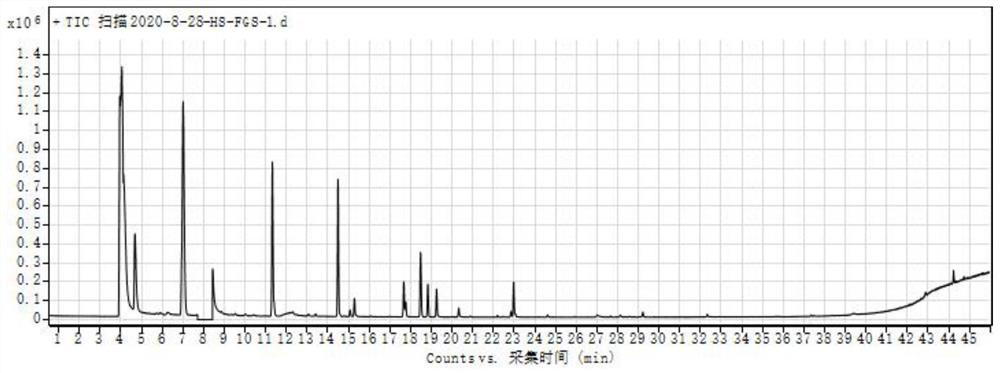

[0045] Determination of content of volatile flavor substances in liquor fermented grains during the fermentation process of embodiment 1

[0046] 1. Draw a standard curve

[0047] (1) Preparation of simulated wine grains

[0048] First, bran husks and five-grain flour (36% of sorghum, 22% of rice, 18% of glutinous rice, 16% of wheat, and 8% of corn, mixed according to the above weight ratio and then pulverized) were respectively ultrasonically soaked in methanol for 30 minutes, and the methanol was poured off. Dry the bran husk and five-grain powder for later use. Add 250g bran shells, 150g five-grain powder and 600g ultrapure water into a beaker and mix them evenly, then put them in a sterilizing pot for sterilization at 115°C for 10 minutes, after the temperature drops to room temperature, add 600g distilled water, 40mL ethanol and 36g lactic acid, mix Set aside.

[0049] (2) Preparation of mixed standards

[0050] The standard substances of 12 kinds of volatile flavor s...

Embodiment 2

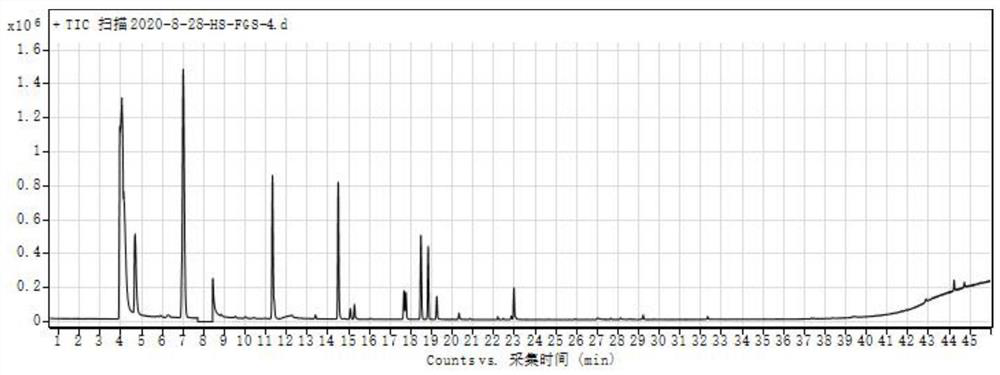

[0073] Example 2 Determination of the content of volatile flavor substances in the fermented grains of liquor leaving the cellar

[0074] There are 2 cellars for Luzhou-flavor liquor and 2 cellars for Maotai-flavor liquor, and an upper layer and a lower layer are taken from each cellar. Accurately weigh 5.0-25.0g of each fermented grains into a 250mL Erlenmeyer flask, add 200-500μL of stable isotope mixed internal standard (the concentration of each substance is 1000mg / L), then add 100mL of 10% ethanol aqueous solution, and cover the bottle Put the lid on a shaker, extract at room temperature at 180rpm for 20min, and filter with a disposable filter (0.2um, nylon membrane) for later use. The extract of the liquor's cellar-exited fermented grains was tested under the same detection conditions as in Example 1, and the response values of volatile flavor compounds in the cellar-exited fermented grains were respectively obtained. According to the response ratio of the compound in...

Embodiment 3

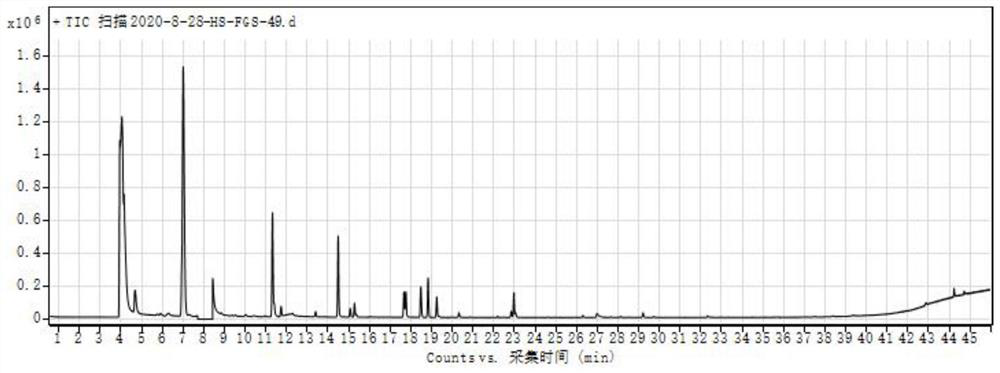

[0079] Embodiment 3 recovery rate and precision measurement

[0080] In order to verify the reliability of the quantitative detection results, the recovery and precision were measured.

[0081] 1. Determination of recovery rate

[0082] The Luzhou-flavor fermented grains (prepared by Example 1) with a fermentation period of 30 days was selected as a sample for determination, and the content of its volatile flavor compounds was quantified (repeated determination 3 times). Two kinds of standard substance mixtures with different concentrations were added to 25g of fermented grains respectively, and the two kinds of spiked samples were measured (repeat 3 times). The recovery rate is calculated by the following formula: standard addition recovery rate = (measured value of the added standard sample - measured value of the sample) ÷ the amount of the added standard × 100%. See Table 5 for details.

[0083] Table 5 Recovery rate of quantitative method for volatile flavor compounds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com