Bismuth-containing 4-series aluminum alloy suitable for brazing without brazing flux and preparation method

A flux-free, aluminum alloy technology, used in welding equipment, metal processing equipment, welding media, etc., can solve the problems of leakage welding, aluminum alloy brazing virtual welding, erosion, etc. The effect of improving welding quality and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

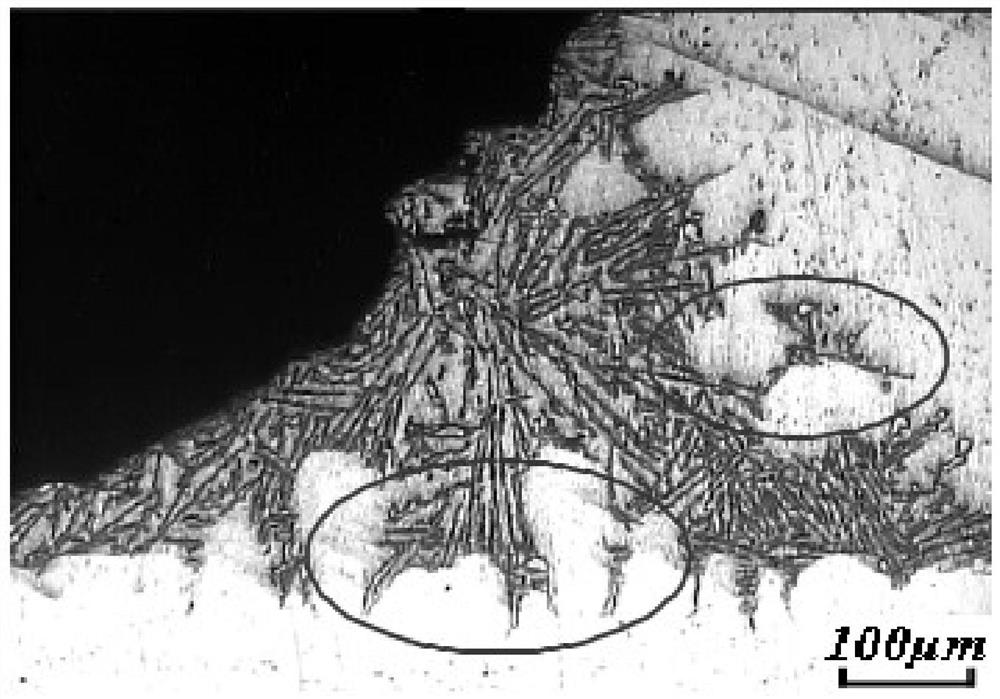

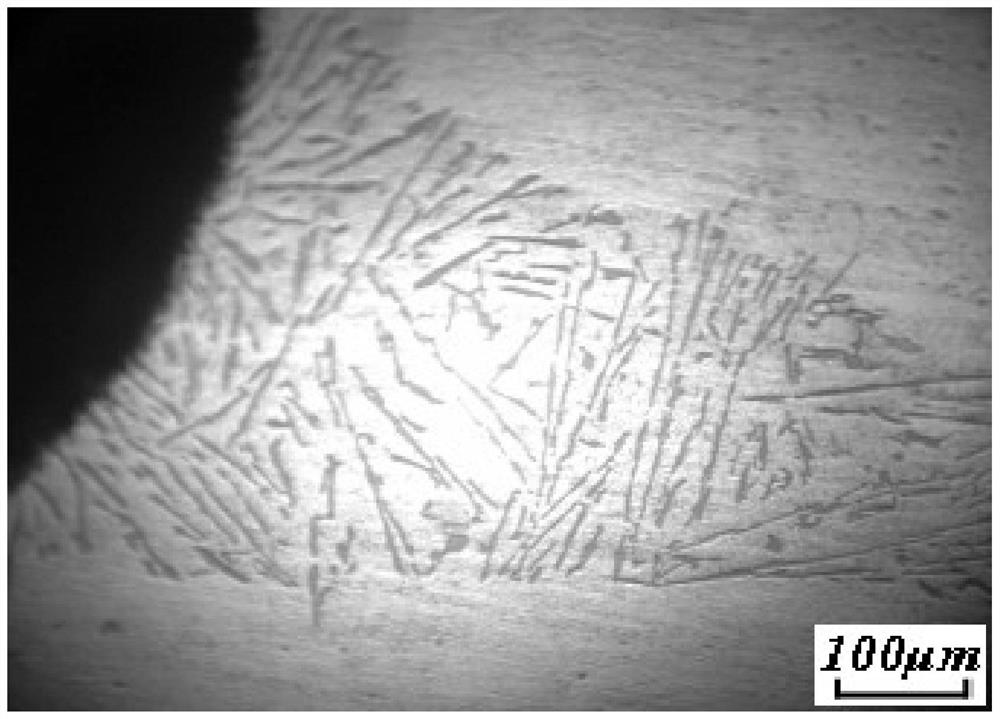

Image

Examples

specific Embodiment approach 1

[0019] Specific Embodiment 1: In this embodiment, the bismuth-containing 4-series aluminum alloy suitable for flux-free brazing consists of Si: 9.5-11%, Mg: 1.3-2.0%, Fe: ≤0.3%, Cu: ≤0.02% , Mn: ≤0.1%, Zn: 0.015-0.04%, Bi: 0.01-0.06%, and the balance is made of Al. Fe, Cu, and Mn are impurity elements.

[0020] The addition of Mg element in the alloy of this embodiment can play a favorable role in vacuum brazing. In the flux-free vacuum brazing process, Mg element has a high vapor pressure and a low boiling point, and can be volatilized under vacuum conditions to remove residual oxygen and moisture in the vacuum and improve the effective vacuum degree. On the other hand, Mg vapor can also penetrate into the surface layer of the base metal under the oxide film and form a low melting point Al-Si-Mg alloy with the diffused Si to melt, thereby destroying the bond between the oxide film and the base metal, and making the molten solder along the aluminum alloy Surface wetting and ...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the bismuth-containing 4-series aluminum alloy suitable for flux-free brazing consists of Si: 10.46%, Mg: 1.91%, Fe: 0.17%, Cu : 0.004%, Mn: 0.003%, Zn: 0.01%, Bi: 0.04%, and the balance is made of Al.

specific Embodiment approach 3

[0025] Specific embodiment three: the preparation method of bismuth-containing 4-series aluminum alloy suitable for flux-free brazing in this embodiment is carried out according to the following steps:

[0026] 1. Melting:

[0027] According to mass percentage, Si: 9.5-11%, Mg: 1.3-2.0%, Fe: ≤0.3%, Cu: ≤0.02%, Mn: ≤0.1%, Zn: 0.015-0.04%, Bi: 0.01-0.06% and Al is the balance and weigh Al-20% Si master alloy, Al-Bi master alloy, Mg ingot, Zn ingot, and aluminum ingot for remelting as raw materials; when charging the furnace, add aluminum ingot for remelting first, then add Al-20 %Si master alloy and Al-Bi master alloy, raise the furnace temperature to 740°C~800°C, when the raw materials in the furnace soften and collapse, add Zn ingots evenly below the melt level in the furnace, and remove the slag after all the furnace materials are melted , after removing slag, control the temperature of the melt to 740-750°C, then add Mg ingots, stir for 10-15 minutes after all the raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com