Preparation method of loess-based geopolymer composite slow-release fertilizer

A technology of geopolymer and slow-release fertilizer, applied in urea compound fertilizer, fertilizer mixture, solid/semi-solid fertilizer, etc., can solve the problems of complex process, high cost, single function, etc., to protect the ecological environment and achieve good slow-release Performance, solve the effect of a single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 A preparation method of a loess-based geopolymer composite slow-release fertilizer:

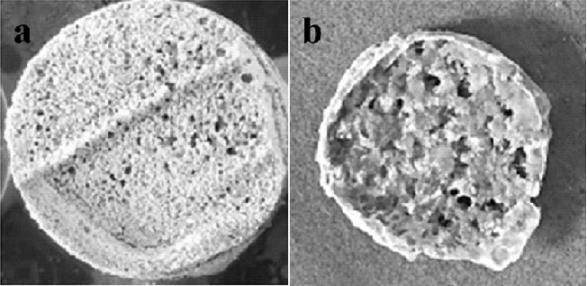

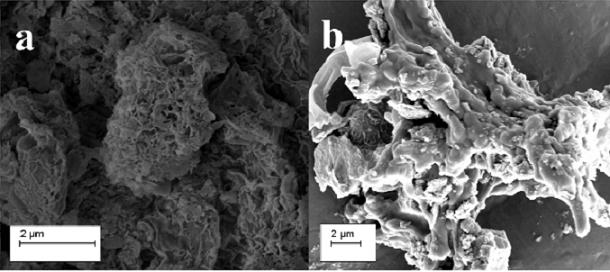

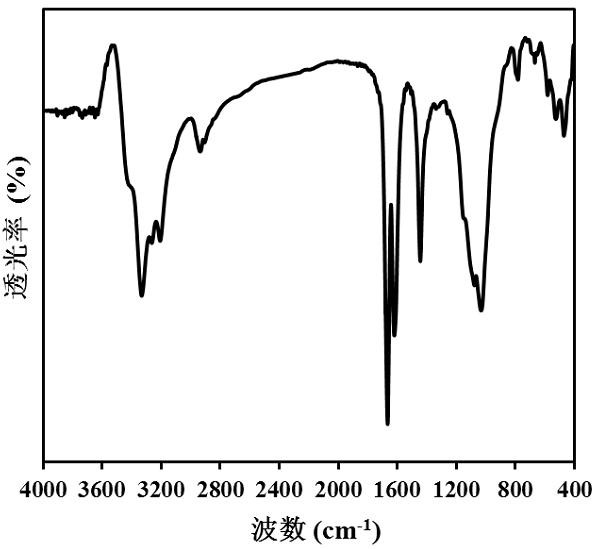

[0056] 【Preparation of loess-based open-pore geopolymer】

[0057] First, the loess was passed through a 300-mesh sieve and dried to prepare 65.0 g of the reaction. Next, in 50 mL of distilled water, slowly add 18.000 g of silicate solid under magnetic stirring, and continue stirring (400 r / min) for 5 min to obtain a colorless solution. Add 2.000 g base activator KOH solid, adjust the rotation speed to 800 r / min and continue stirring until dissolved. Thirdly, add 65.0 g of prepared loess, stir overnight at room temperature for 12 h, add 1.800 g of surfactant, increase the speed to 1000 r / min, and stir for 15 min. Add 2.4 mL foaming agent aluminum powder solution (30%) dropwise, slow down the amount of foaming by controlling the dropping speed, and then continue to stir for 10 min to form a uniform cloudy solution. Finally, pour into the mold and dry in an oven at 80 °C for ...

Embodiment 2

[0061] Example 2 A preparation method of a loess-based geopolymer composite slow-release fertilizer:

[0062] 【Preparation of loess-based geopolymer】

[0063] First, the loess was passed through a 300-mesh sieve and dried to prepare 50.0 g of the reaction. Next, slowly add 15.000 g of sodium silicate (Na 2 SiO 3 9H 2 O) solid, then continue stirring (400 r / min) for 5 min to obtain a colorless solution. Add 2.500 g of base activator NaOH solid, adjust the rotation speed to 800 r / min and continue stirring until dissolved. Third, add 50.0 g of loess prepared and stir overnight at room temperature for 16 h. Add 1.600 g cardamom oil, increase the speed to 1000r / min, and stir for 10-20 min. Add 3.8 mL of foaming agent H dropwise 2 o 2 solution (30%), slow down the amount of foaming by controlling the drop rate, and then continue to stir for 10 min to form a uniform turbid solution. Finally, it was poured into the mold and dried in an oven at 80°C for 36 hours to obtain a lo...

Embodiment 3

[0067] Example 3 A preparation method of a loess-based geopolymer composite slow-release fertilizer:

[0068] 【Preparation of loess-based geopolymer】

[0069] First, the loess was passed through a 300-mesh sieve and dried to prepare 50.0 g of the reaction. Next, in 50 mL of distilled water, slowly add 18.000 g of potassium silicate solid under magnetic stirring, and then continue stirring (400 r / min) for 5 min to obtain a colorless solution. Add 1.300 g of base activator NaOH solid, adjust the rotation speed to 800 r / min and continue stirring until dissolved. Third, add 50.0 g of loess prepared and stir overnight at room temperature for 18 h. Add 1.400 g soybean oil, increase the speed to 1000 r / min, and stir for 10-20 minutes. Add 2.8 mL of foaming agent H dropwise 2 o 2 solution (25%), the amount of foaming was slowed down by controlling the dropping speed, and then continued to stir for 10 min to form a uniform turbid solution. Finally, it was poured into the mold and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com