A kind of method for selecting copper and nickel from copper-nickel ore

A technology for copper-nickel and ore beneficiation, applied in the field of copper-nickel beneficiation of copper-nickel ore, can solve problems such as low recovery rate, and achieve the effects of reducing MgO content, improving copper-nickel recovery rate, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

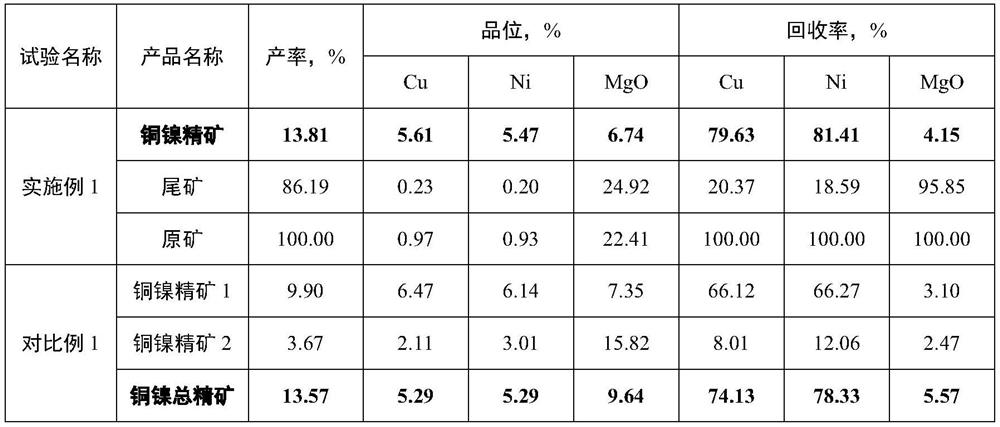

[0048] This embodiment provides a method for selecting copper and nickel from a copper-nickel ore, wherein the copper-nickel ore has a copper grade of 0.95% and a nickel grade of 0.92%.

[0049] The main valuable elements of the copper-nickel ore are copper and nickel, followed by recyclable precious metals gold, silver, platinum and palladium. Nickel minerals are mainly pyrite and pyrite, copper minerals are mainly chalcopyrite, chalcopyrite and a small amount of chalcopyrite, and other metal minerals are mainly pyrrhotite, pyrite, magnetite Ore, chromite, rare and precious metal ore are tellurium silver ore, natural gold, silver gold ore, gold and silver ore, tellurium bismuth palladium ore, tellurium bismuth (platinum) palladium ore, arsenic platinum ore, etc. The gangue minerals are mainly serpentine stone. Copper and nickel minerals are closely related to magnetite, and magnetite usually grows at the sulfide grain boundary.

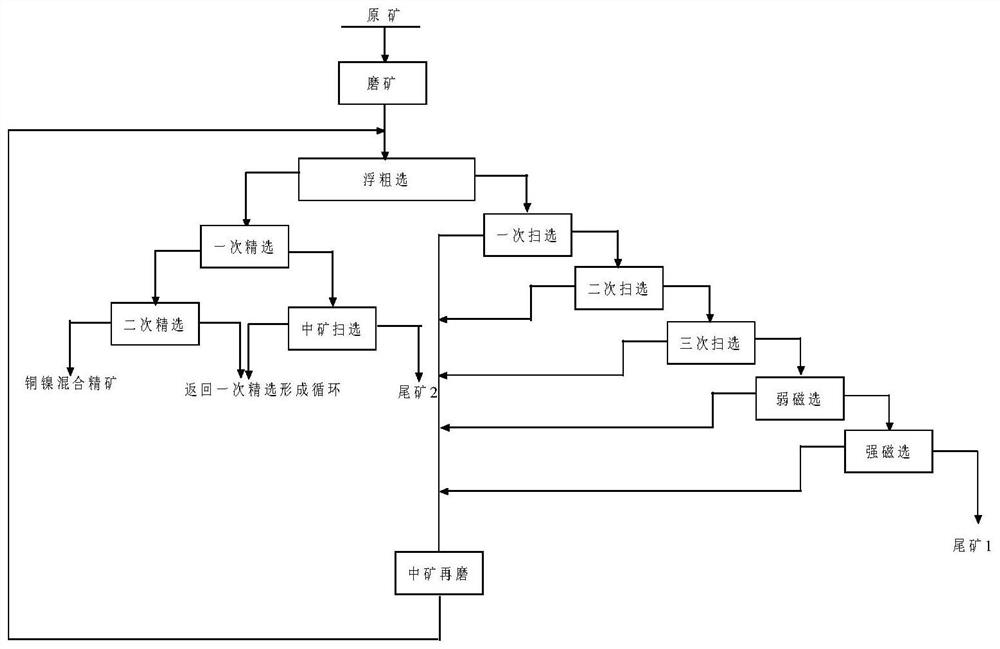

[0050] The schematic flow chart of the metho...

Embodiment 2

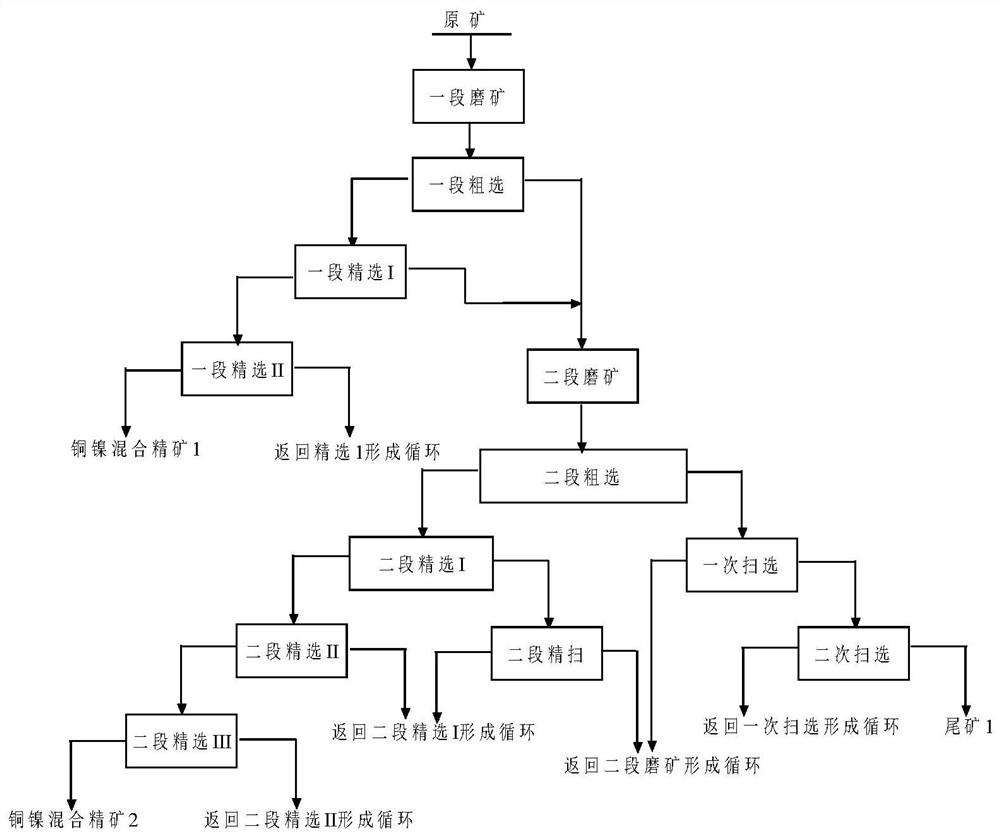

[0077] This embodiment provides a method for selecting copper and nickel from a copper-nickel ore. The difference from Example 1 lies in the ore feeding. The copper-nickel ore in this embodiment has a copper grade of 0.87% and a nickel grade of 1.30%.

[0078] The main valuable elements of the copper-nickel ore are copper and nickel, followed by recyclable precious metals gold, silver, platinum and palladium. Nickel minerals are mainly nickel pyrite, copper-nickel iron ore, purple sulfur nickel ore, copper minerals are mainly chalcopyrite, chalcopyrite, chalcopyrite, and other metal minerals are mainly pyrrhotite, tetragonal pyrite Ore, pyrite, magnetite, rare and precious metal ore are natural gold, silver-gold ore, gold-silver ore, bismuth tellurium palladium ore, bismuth tellurium (platinum) palladium ore, etc. The gangue mineral is mainly serpentine. The structure of the ore is complex, and a large amount of magnetite and magnesia-bearing gangue minerals are filled in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com