Oxidation treatment process for arsenic-containing acidic wastewater

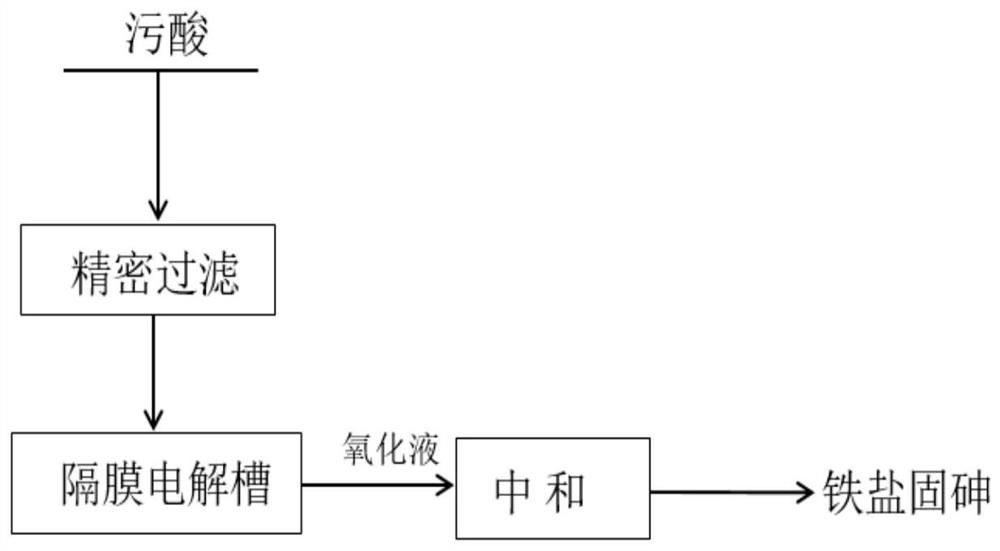

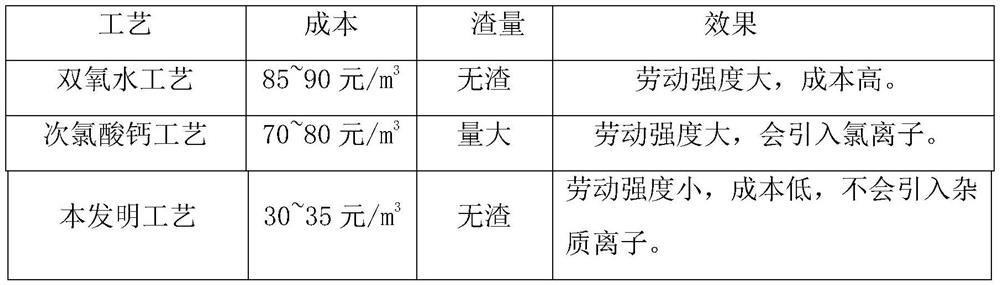

A technology for oxidation treatment and arsenic pollution acid, which is applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage treatment equipment, etc. It can solve the problem of high cost of arsenic oxidation treatment, achieve strong applicability, low investment, The effect of reducing curing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

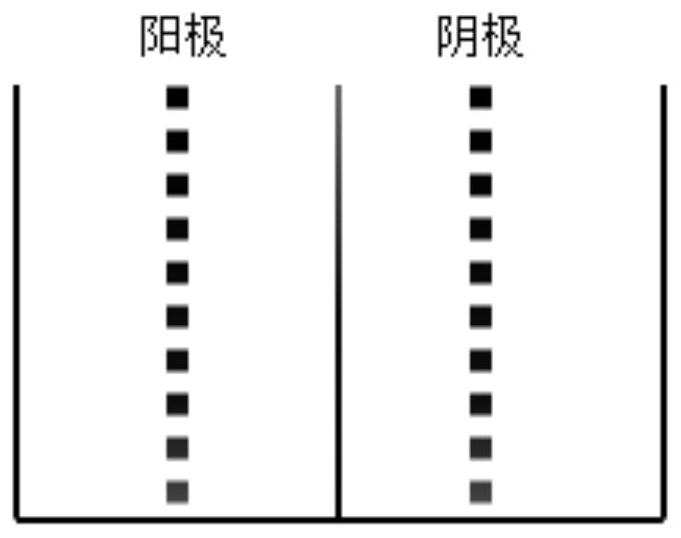

Embodiment 1

[0046] The content of arsenic in the copper concentrate in a copper smelter in northern my country is 0.45%, and the polluted acid produced during the smelting process contains 108g / L of sulfuric acid, 10.2g / L of total arsenic, 8.6g / L of trivalent arsenic, and 50.6mg of SS / L, conductivity 126.5ms / cm. The above-mentioned water quality is filtered by PVDF precision filter membrane, and then passed into the anode chamber of the anion diaphragm electrolyzer, and the cathode chamber of the electrolyzer is 150g / L sodium chloride solution; the cathode liquid level is 1.0cm higher than the anode liquid level, and the current density is 250A / m 2 , Control residence time 2.5h. The liquid after anodic oxidation is neutralized by limestone and enters the traditional iron salt solidification process. The concentration of arsenic in the solid waste slag toxic leachate after solidification is 0.2 mg / L, which is lower than the 5 mg / L required by the national hazardous waste identification st...

Embodiment 2

[0048] The arsenic content in copper and gold mines in a copper smelting plant in Fujian is 0.68%. Among the dirty acid produced during the smelting process, sulfuric acid: 95g / L, total arsenic 12.2g / L, trivalent arsenic 9.3g / L, SS120.6mg / L L, conductivity 136.5ms / cm. The above-mentioned water quality is passed through the anode chamber of the PP diaphragm electrolyzer after being precisely filtered by the ceramic membrane. The cathode chamber of the electrolyzer is 180g / L sodium sulfate solution; the cathode liquid level is 2.5cm higher than the anode liquid level and the current density is 350A / m 2 , Control residence time 3.5h. After anodizing, the solution is neutralized with calcium oxide and then enters the traditional iron salt curing process. The concentration of arsenic in the solid waste slag toxic leachate after solidification is 1.5mg / L, which is lower than the 5mg / L required by the national hazardous waste identification standard.

Embodiment 3

[0050] The arsenic content in a smelter of a lead-zinc mine in Guangdong is 0.3%. In the polluted acid produced during the smelting process, sulfuric acid: 98g / L, total arsenic 9.2g / L, trivalent arsenic 7.1g / L, SS150.6mg / L, Conductivity 106.5ms / cm. The above-mentioned water quality is passed through the anode chamber of the anion diaphragm electrolyzer after being precisely filtered by the ceramic membrane. The cathode chamber of the electrolyzer is 200g / L sodium nitrate solution; the cathode liquid level is 2.0cm higher than the anode liquid level and the current density is 250A / m 2 , Control residence time 1.5h. The liquid after anodic oxidation is neutralized by limestone and enters the traditional iron salt solidification process. The concentration of arsenic in the solid waste slag toxic leachate after solidification is 1.5mg / L, which is lower than the 5mg / L required by the national hazardous waste identification standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap