Fluorine-containing modified polysiloxane as well as preparation method and application thereof

A polysiloxane and modification technology, which is applied in the field of fluorine-containing modified polysiloxane and its preparation, can solve the problem of difficulty in controlling the viscosity, fluorine content and content of other groups of fluorosilicone oil, and the reaction is not easy to control, Solve the problem of low yield of silicone oil, and achieve the effects of easy control of the reaction, good yield and quality, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

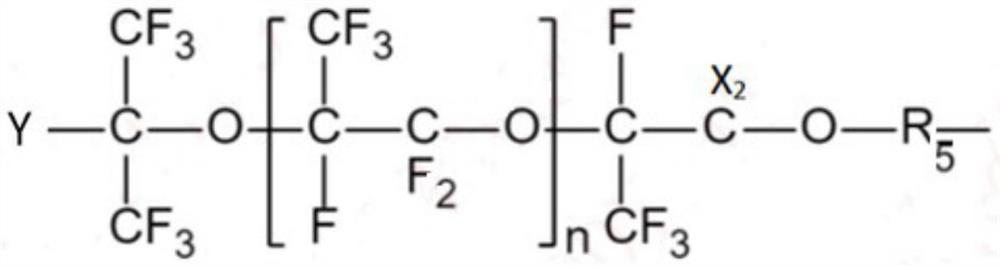

[0027] (1) Dissolve 328g (0.5mol) of fluorine-containing dichlorosilane and 64.5g (0.5mol) of dimethyldichlorosilane in 200ml of trifluorotrichloroethane, add dropwise to 500ml of deionized water and hydrolyze at 60°C for 1.5h , followed by neutralization, filtration, drying, removal of solvent at 50mmHg, 50°C to obtain 294g (CH 3 )(R f )-SiO 2 / 2 :(CH 3 ) 2 SiO 2 / 2 =1:1 fluorinated hydrolyzed copolymer.

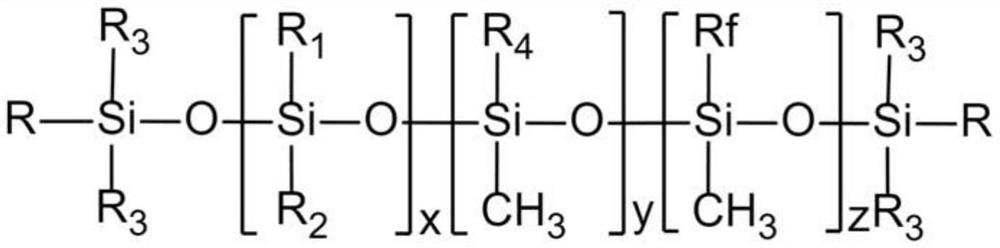

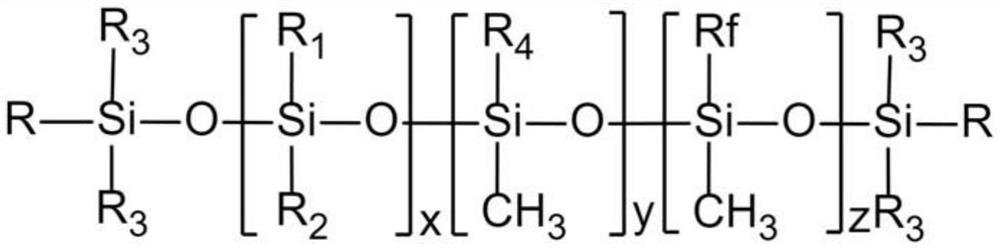

[0028] (2) Then add 12.48g (3.63×10 -2 mol) tetravinylcyclotetrasiloxane, 33g (0.1089mol) octamethylcyclotetrasiloxane, 0.236g (1.452×10 -3 ) hexamethyldisiloxane, followed by adding catalyst 0.5part perfluorosulfonic acid resin and reacting at 90°C for 8 hours. After the reaction was completed, the sulfonic acid resin was filtered off, decolorized, and 327g product was obtained by devolatilization at 140°C / 5mmHg for 25min. Viscosity 587mm 2 / s, the product has the following molecular formula:

[0029] (Me 3 SiO 1 / 2 ) 1.85 (HOME 2 SiO 1 / 2 ) 0.15 (CH 3 R f SiO...

Embodiment 2

[0031] (1) Dissolve 328g (0.5mol) of fluorine-containing dichlorosilane and 64.5g (0.5mol) of dimethyldichlorosilane in 200ml of trifluorotrichloroethane, add dropwise to 500ml of deionized water and hydrolyze at 60°C for 1.5h , followed by neutralization, filtration, drying, removal of solvent at 50mmHg, 50°C to obtain 292g (CH 3 )(R f )-SiO 2 / 2 :(CH 3 ) 2 SiO 2 / 2 =1:1 fluorinated hydrolyzed copolymer.

[0032] (2) Then add 12.40g (3.61×10 -2 mol) tetravinylcyclotetrasiloxane, 32g (0.1081mol) octamethylcyclotetrasiloxane, 0.268g (1.442×10 -3 ) divinyltetramethyldisiloxane, then add catalyst 0.5part perfluorosulfonic acid resin and react at 90°C for 8 hours, after the reaction is completed, filter out the sulfonic acid resin, decolorize, and devolatilize at 140°C / 5mmHg for 25min to obtain Product, viscosity 585mm 2 / s, the product has the following molecular formula:

[0033] (Me 2 ViSiO 1 / 2 ) 1.87 (HOME2 SiO 1 / 2 ) 0.13 (CH 3 R f SiO) 305 (Me 2 SiO) 593 (MeV...

Embodiment 3

[0035] (1) Dissolve 32.8g (0.05mol) of fluorine-containing dichlorosilane and 6.45g (0.05mol) of dimethyldichlorosilane in 20ml of trifluorotrichloroethane, add dropwise to 50ml of deionized water and hydrolyze at 60°C for 1.5 h, followed by neutralization, filtration, drying, removal of solvent at 50mmHg, 50°C to obtain 29.5g (CH 3 )(R f )-SiO 2 / 2 :(CH 3 ) 2 SiO 2 / 2 =1:1 fluorinated hydrolyzed copolymer.

[0036] (2) Then add 1.31g (5.47×10 -3 mol) Tetramethylcyclotetrasiloxane, 0.17g (1.093×10 -3 ) hexamethyldisiloxane, then add catalyst 0.5part perfluorosulfonic acid resin, react at 120°C for 4h, filter out the sulfonic acid resin after the reaction, decolorize, and devolatilize at 140°C / 5mmHg for 20min to obtain the product, Viscosity 125mm 2 / s, the product has the following molecular formula:

[0037] (Me 3 SiO 1 / 2 ) 1.95 (HOME 2 SiO 1 / 2 ) 0.05 (CH 3 R f SiO) 42 (Me 2 SiO) 41 (MeHSiO) 20 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com