Medical hard PVC material with high heat resistance and electron beam sterilization resistance and preparation method thereof

A PVC material and high heat resistance technology, which are applied in the field of high heat resistance and radiation sterilization medical rigid PVC materials and their preparation, can solve problems such as mechanical properties decline and yellowing, and achieve the effect of efficiently absorbing hydrogen chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

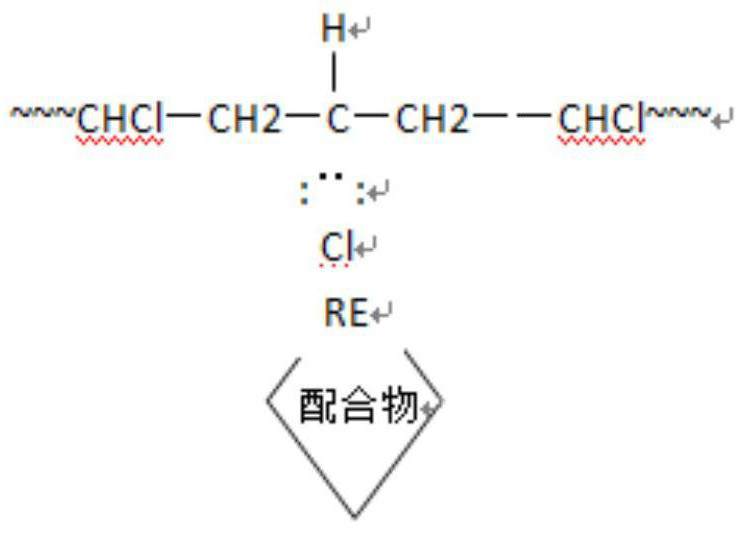

Method used

Image

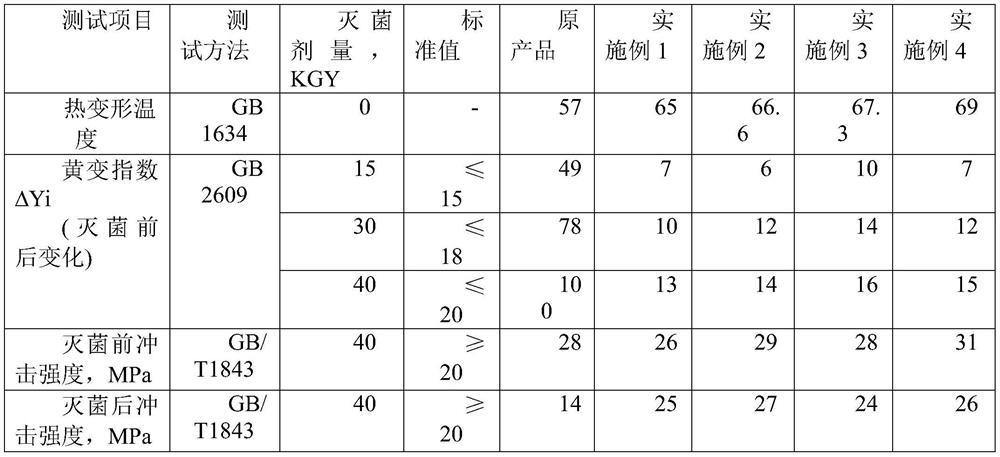

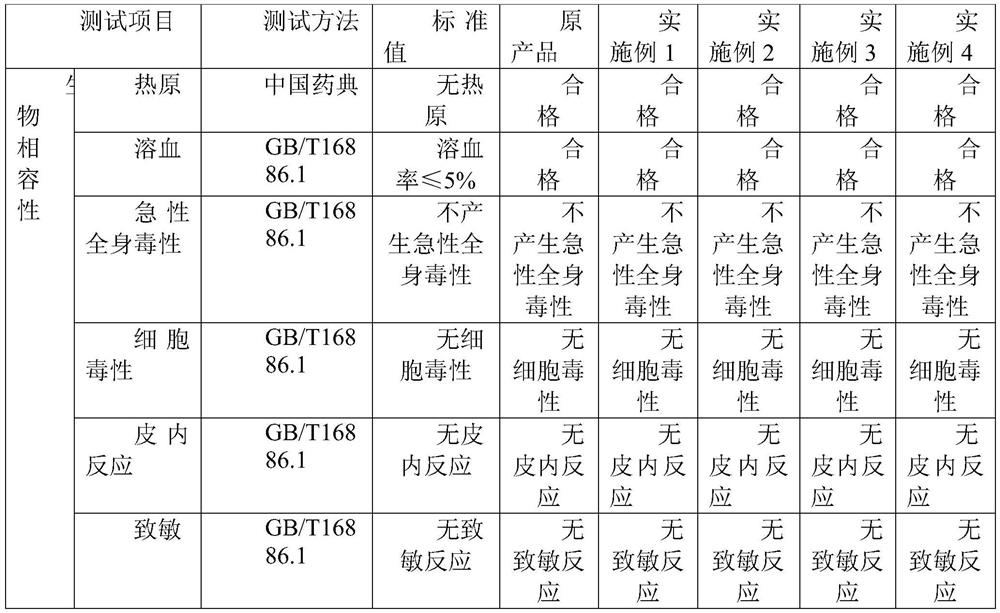

Examples

Embodiment 1

[0037] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0038] Medical PVC resin powder: 100.0 parts;

[0039] Organotin stabilizer: 2.0 parts;

[0040] Heat-resistant modified resin: 15.0 parts;

[0041] Impact modifier: 5.0 parts;

[0042] Processing aid: 2.0 parts;

[0043] Auxiliary heat stabilizer: 5.0 parts;

[0044] Antioxidant: 0.5 parts;

[0045] Composite free radical quencher: 2.0 parts;

[0046] Lubricant: 0.6 parts.

[0047] The medical PVC resin powder is a suspension method PVC resin with a polymerization degree of 500-800; the organotin stabilizer is a mercaptan methyl tin stabilizer; the heat-resistant modified resin is made of 30%-50 A mixture of α-methylstyrene polymer, 30-40% styrene-maleic anhydride copolymer and 10-30% styrene-acrylonitrile; the impact modifier is styrene-type impact-modified agent; the processing aid is a methacrylate processing aid; the auxiliary stabilizer is epoxy linseed...

Embodiment 2

[0053] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0054] Medical PVC resin powder: 100.0 parts;

[0055] Organotin stabilizer: 3.0 parts;

[0056] Heat-resistant modified resin: 20.0 parts

[0057] Impact modifier: 8.0 parts;

[0058] Processing aid: 1.5 parts;

[0059] Auxiliary heat stabilizer: 3.0 parts;

[0060] Antioxidant: 1.0 parts;

[0061] Composite free radical quencher: 1.0 parts;

[0062] Lubricant: 0.8 parts.

[0063] The medical PVC resin powder is a suspension method PVC resin with a polymerization degree of 500-800; the organotin stabilizer is a mercaptan methyl tin stabilizer; the heat-resistant modified resin is made of 30%-50 A mixture of α-methylstyrene polymer, 30-40% styrene-maleic anhydride copolymer and 10-30% styrene-acrylonitrile; the impact modifier is styrene-type impact-modified agent; the processing aid is a methacrylate processing aid; the auxiliary stabilizer is epoxy linseed ...

Embodiment 3

[0066] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0067] Medical PVC resin powder: 100 parts;

[0068] Organotin stabilizer: 3.0 parts;

[0069] Heat-resistant modified resin: 20.0 parts;

[0070] Impact modifier: 7.0 parts;

[0071] Processing aid: 1.0 part;

[0072] Auxiliary heat stabilizer: 2.0 parts;

[0073] Antioxidant: 0.5 part;

[0074] Composite free radical quencher: 1.5 parts;

[0075] Lubricant: 1.0 parts.

[0076] The medical PVC resin powder is a suspension method PVC resin with a polymerization degree of 500-800; the organotin stabilizer is a mercaptan methyl tin stabilizer; the heat-resistant modified resin is made of 30%-50 A mixture of α-methylstyrene polymer, 30-40% styrene-maleic anhydride copolymer and 10-30% styrene-acrylonitrile; the impact modifier is styrene-type impact-modified agent; the processing aid is a methacrylate processing aid; the auxiliary stabilizer is epoxy linseed oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com