A kind of high-strength and medium-conductivity copper-nickel-silicon-tin-magnesium alloy foil and processing method thereof

A copper-nickel-silicon, magnesium alloy technology, applied in the direction of metal rolling, can solve the problem of high temperature softening resistance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

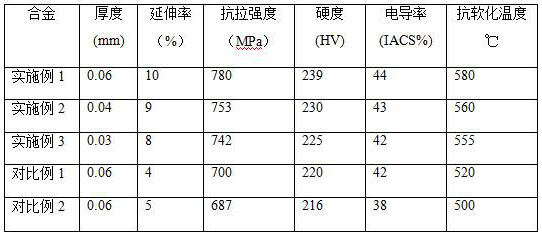

Examples

Embodiment 1

[0035] (1) Smelting and casting: First, the cathode copper and nickel plate are smelted and added to the kettle, and the smelting temperature is set to 1290°C. When the temperature in the kettle reaches 1240°C, silicon ingots, copper-magnesium alloys and copper-tin alloys are added, and the smelting is continued for 25 minutes. Casting at a temperature of 1250°C, casting speed of 90mm / min, and processing into a square ingot (205mm*605mm); the composition range is (mass percentage), Ni 2.6%, Si 0.45%, Sn 0.08%, Mg 0.12%, The balance is copper and impurities below 0.1%;

[0036] (2) Solid solution: Heating by step-by-step homogenization heating, the temperature range is 795~1200 ℃, ten cells are divided in the furnace, each cell independently controls the temperature, the first cell is 795 ° C, and the tenth cell is 795 ° C. 1200 ℃, the other areas are raised in steps at 45 ℃, the speed is 12m / min, and then hot working at 900 ℃, the total processing rate is 96%, the final rollin...

Embodiment 2

[0048] (1) Smelting and casting: First, the cathode copper and nickel plate are smelted and added to the kettle, and the smelting temperature is set to 1270°C. When the temperature in the kettle reaches 1220°C, silicon ingots, copper-magnesium alloys and copper-tin alloys are added, and the smelting continues for 30 minutes. Casting at a temperature of 1260°C, a casting speed of 90mm / min, processing into an ingot, the size of the ingot is (205mm*605mm); the composition range is (mass percentage), Ni 2.6%, Si 0.65%, Sn 0.06% , Mg 0.18%, Mg 0.18%, the balance is copper and impurities below 0.1%.

[0049] (2) Solid solution: Heating by step-by-step homogenization heating, the temperature range is 795~1200 ℃, ten cells are divided in the furnace, each cell independently controls the temperature, the first cell is 795 ° C, and the tenth cell is 795 ° C. 1200 ℃, other areas are raised in steps at 45 ℃, the speed is 12m / min, and then hot working is carried out at a temperature of 880...

Embodiment 3

[0062] (1) Smelting and casting: First, the cathode copper and nickel plate are smelted and added to the kettle, and the smelting temperature is set to 1270 ℃. When the temperature in the kettle reaches 1260 ℃, silicon ingots, copper-magnesium alloys and copper-tin alloys are added, and the smelting is continued for 25 minutes. Casting at a temperature of 1230°C, a casting speed of 90mm / min, and processing into an ingot (205mm*605mm); the composition range is (mass percentage), Ni2.75%, Si 0.35%, Sn 0.06%, Mg 0.15% , the balance is copper and impurities below 0.1%;

[0063] (2) Solid solution: Heating by step-by-step homogenization heating, the temperature range is 795~1200 ℃, ten cells are divided in the furnace, each cell independently controls the temperature, the first cell is 795 ° C, and the tenth cell is 795 ° C. 1200 ℃, other areas are raised in steps at 45 ℃, the speed is 12m / min, and then hot working is carried out at a temperature of 930 ℃, the total processing rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com