NiFe-PBAs-F catalyst with multistage structure as well as preparation method and application thereof

A nife-pbas-f, catalyst technology, applied in the field of clean energy and electrochemistry, can solve the problems of metal ion aggregation, metal skeleton collapse, high overpotential for oxygen evolution reaction, and unfavorable electrocatalytic oxygen-producing species transport.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In a first aspect, the present invention provides a method for preparing a NiFe-PBAs-F catalyst with a multi-level structure, comprising the steps of:

[0030] React foamed nickel in a mixed solution of nickel salt and hexamethylenetetramine to obtain Ni(OH) 2 Nanosheets;

[0031] Ni(OH) to be grown on a nickel foam substrate 2 The nanosheets were placed in a mixed solution of nickel salt, sodium citrate and potassium ferricyanide, reacted, and left to stand for a set time after the reaction to prepare NiFe-PBAs@Ni(OH) 2 multi-level structure;

[0032] The prepared NiFe-PBAs@Ni(OH) 2 Hierarchical structure and NH 4 F was heat-treated in an inert atmosphere to obtain a NiFe-PBAs-F catalyst with a hierarchical structure.

[0033]In some embodiments, the pretreatment method of the nickel foam is: sequentially washing with hydrochloric acid, acetone and ethanol.

[0034] Further, the pretreated nickel foam is placed in ethanol for later use.

[0035] In some embodime...

Embodiment 1

[0053] A NiFe-PBAs-F catalyst with excellent electrocatalytic oxygen evolution performance and its preparation method and application, comprising the following steps:

[0054] (1) Ultrasonic cleaning of nickel foam conductive substrate:

[0055] First cut with scissors to obtain a foamed nickel conductive substrate with a size of 2cm×4cm, then ultrasonically clean it with hydrochloric acid, acetone, and ethanol for 10 minutes, and finally store it in an ethanol solvent.

[0056] (2) Synthesis of Ni(OH) by hydrothermal method 2 Nanosheets:

[0057] 0.7 g of nickel nitrate hexahydrate and 0.7 g of hexamethylenetetramine were dissolved in 35 ml of deionized water, and stirred for 15 minutes to obtain a light green solution. Then the solution is transferred to a reaction kettle with 50 milliliters of polytetrafluoroethylene liners, and the clean foamed nickel obtained in (1) is placed in the still, and subjected to hydrothermal reaction at 100° C. for 10 hours, and naturally coo...

Embodiment 2

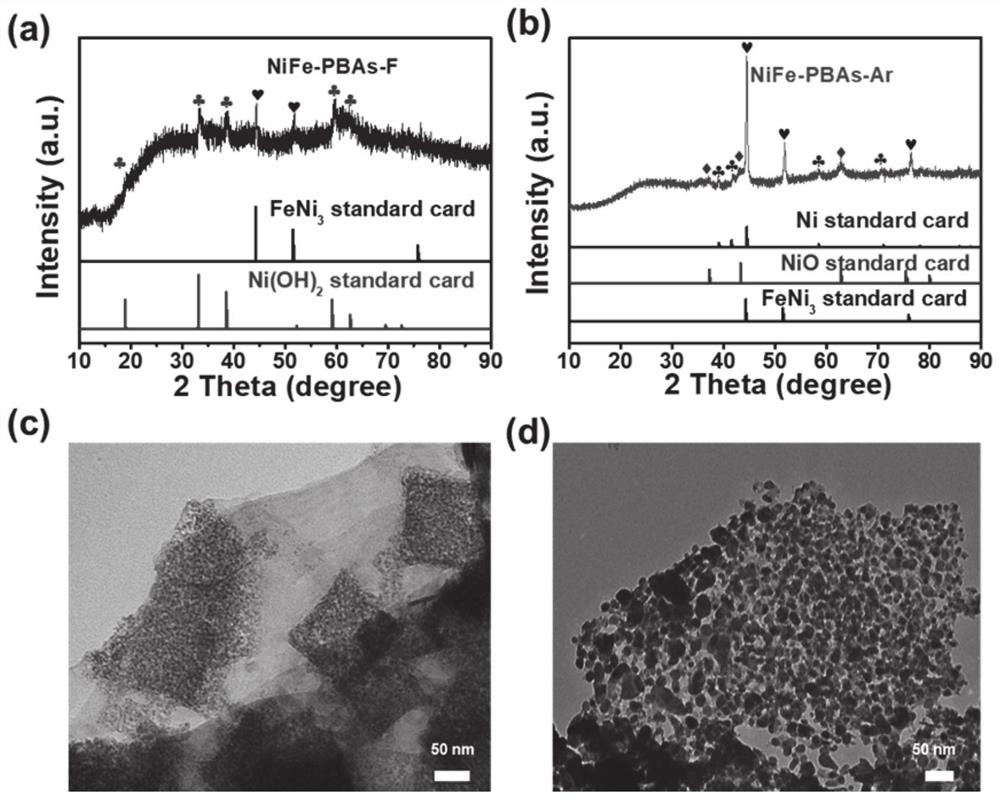

[0063] This embodiment prepares the NiFe-PBAs-F catalyst of different content fluorine amount, and preparation method is the same as embodiment 1, and difference is: the amount that fluorination adopts in the step (4) changes to: 0g, 80mg, 320mg, the prepared product The oxygen catalysts are labeled as NiFe-PBAs-Ar, NiFe-PBAs-F-80mg, NiFe-PBAs-F-320mg, respectively.

[0064] Ni(OH) 2 Nanosheets, NiFe-PBAs@Ni(OH) 2 Hierarchical structure, and morphology schematic diagram and phase analysis of NiFe-PBAs-F catalyst:

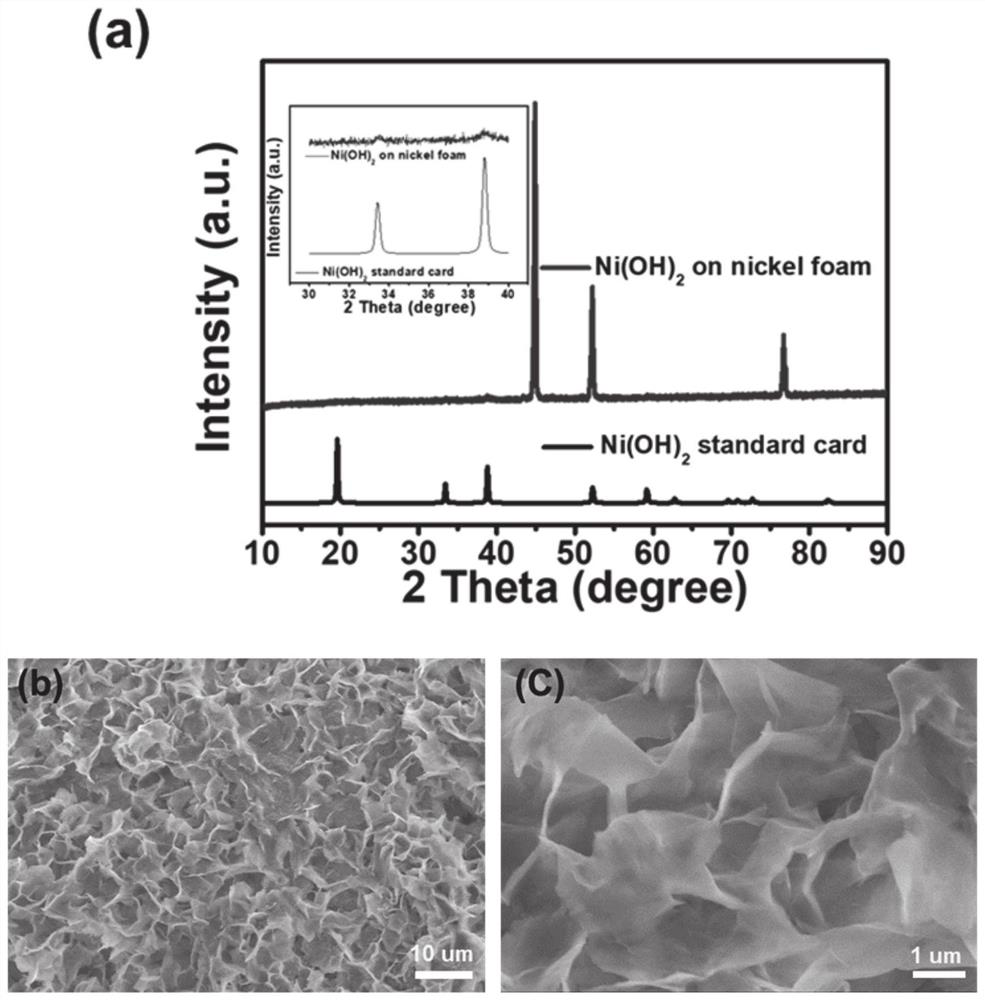

[0065] The Ni(OH) that embodiment 1 prepares 2 The XRD and SEM patterns of the nanosheets are as follows: figure 1 shown. From figure 1 It can be seen that Ni(OH) 2 The nanosheets grow uniformly on the nickel foam.

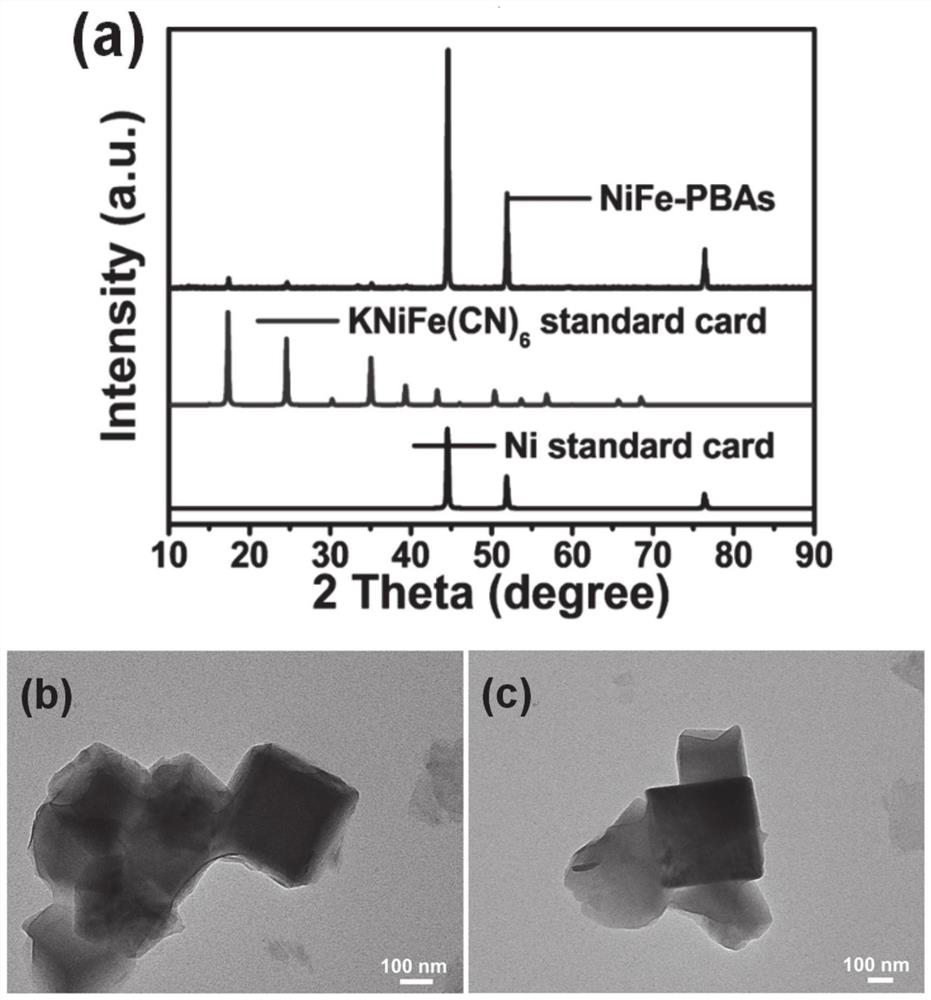

[0066] NiFe-PBAs@Ni(OH) prepared by embodiment 1 2 Such as figure 2 as shown, figure 2 (a) It can be seen that the substance generated after ion exchange is NiFe-PBAs@Ni(OH) 2 ,pass figure 2 (b-c) Low-magnification TEM shows that cubic Ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com