Protein solid brewing particles and preparation method thereof

A technology of solid powder and protein, which is applied in the field of health care products and food, and can solve problems such as difficult dispersion, easy deterioration of products, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A protein solid brewing granule, mainly comprising: 50 parts of modified oyster protein powder, 15 parts of collagen powder, 15 parts of compound fruit and vegetable powder, 8 parts of inulin, 4 parts of polydextrose, and 4 parts of maltose in parts by weight Essence, 2 parts vitamin E and 2 parts vitamin C.

[0029] A method for preparing protein solid brewing granules, mainly comprising the following steps:

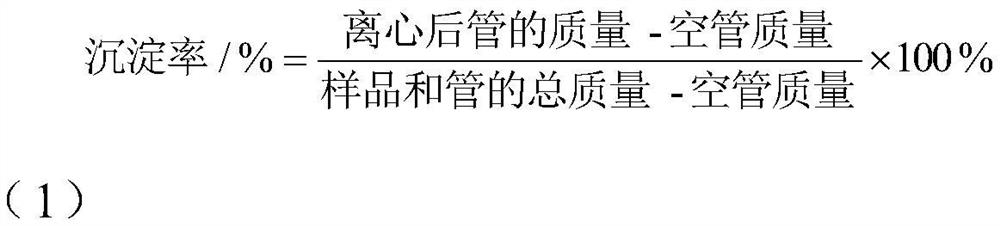

[0030] (1) After fresh oysters were cultured in seawater rich in inorganic selenium for 3 days, the oyster meat was taken out, and the oyster meat and protease solution were mixed at a mass ratio of 1:20, and after enzymatic hydrolysis at room temperature for 6 hours, then at a temperature of 90 The mixture was inactivated for 20 minutes under the condition of ℃, and the mixture was centrifuged to separate, and the supernatant was taken, and the supernatant and yeast were mixed according to the mass ratio of 50:1, and the fermentation and deodorization treatment ...

Embodiment 2

[0038] A protein solid brewing granule, mainly comprising: 50 parts of modified oyster protein powder, 15 parts of collagen powder, 15 parts of compound fruit and vegetable powder, 8 parts of inulin, 4 parts of polydextrose, and 4 parts of maltose in parts by weight Essence, 2 parts vitamin E and 2 parts vitamin C.

[0039] A method for preparing protein solid brewing granules, mainly comprising the following steps:

[0040] (1) After fresh oysters were cultured in seawater rich in inorganic selenium for 3 days, the oyster meat was taken out, and the oyster meat and protease solution were mixed at a mass ratio of 1:20, and after enzymatic hydrolysis at room temperature for 6 hours, then at a temperature of 90 The mixture was inactivated for 20 minutes under the condition of ℃, and the mixture was centrifuged to separate, and the supernatant was taken, and the supernatant and yeast were mixed according to the mass ratio of 50:1, and the fermentation and deodorization treatment ...

Embodiment 3

[0047] A protein solid brewing granule, mainly comprising: 50 parts of modified oyster protein powder, 15 parts of collagen powder, 15 parts of compound fruit and vegetable powder, 8 parts of inulin, 4 parts of polydextrose, and 4 parts of maltose in parts by weight Essence, 2 parts vitamin E and 2 parts vitamin C.

[0048] A method for preparing protein solid brewing granules, mainly comprising the following steps:

[0049] (1) After fresh oysters were cultured in seawater rich in inorganic selenium for 3 days, the oyster meat was taken out, and the oyster meat and protease solution were mixed at a mass ratio of 1:20, and after enzymatic hydrolysis at room temperature for 6 hours, then at a temperature of 90 The mixture was inactivated for 20 minutes under the condition of ℃, and the mixture was centrifuged to separate, and the supernatant was taken, and the supernatant and yeast were mixed according to the mass ratio of 50:1, and the fermentation and deodorization treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com