High-water-solubility chlortetracycline hydrochloride soluble powder and preparation method thereof

A chlortetracycline hydrochloride, water-soluble technology, applied in the field of highly water-soluble chlortetracycline hydrochloride soluble powder and its preparation, to achieve the effects of saving labor costs, changing solubility, and reducing the difficulty of drug administration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

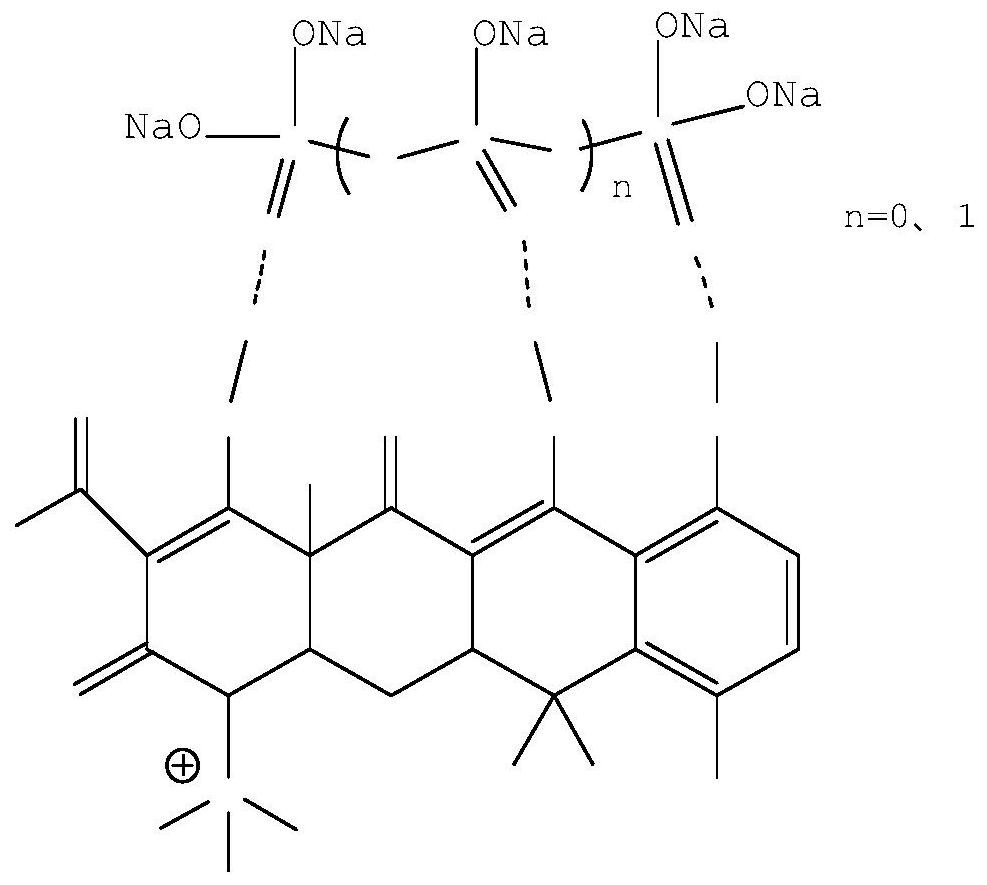

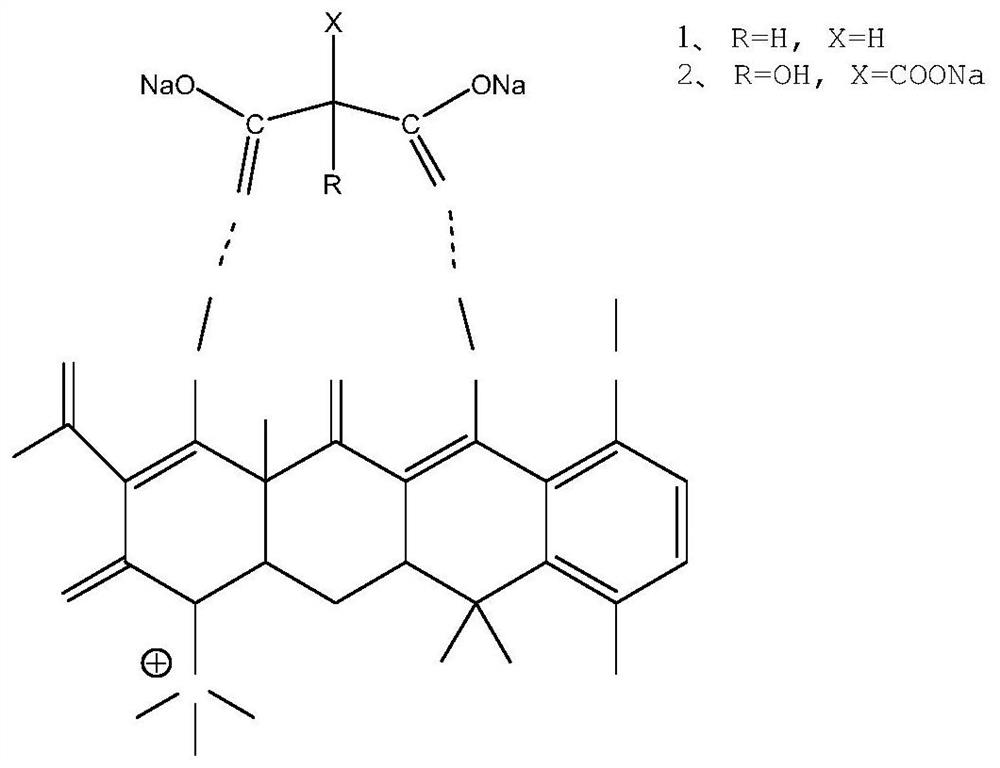

Image

Examples

Embodiment 1

[0024] Prescription Screening:

[0025] The purpose of the present invention is to obtain stable highly water-soluble chlortetracycline hydrochloride soluble powder, and the prescription screening process mainly investigates two indexes, solubility and stability.

[0026] ①Solubility test

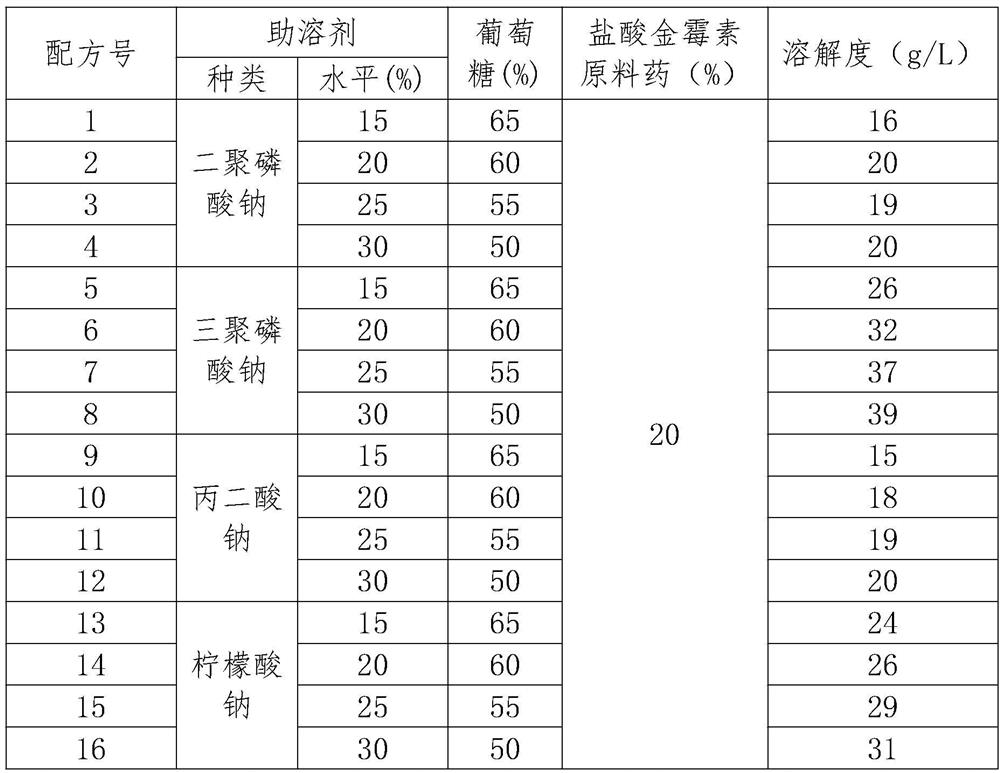

[0027] On the basis of a large number of previous experiments, sodium dipolyphosphate, sodium tripolyphosphate, sodium malonate, and sodium citrate were selected as co-solvents, and glucose was used as a diluent to quantify to 100g, and the level of co-solvents was screened; a single co-solvent The solvent test results are shown in Table 1:

[0028] Table 1 Single cosolvent test results

[0029]

[0030] The results showed that both sodium dipolyphosphate and sodium tripolyphosphate as co-solvents could significantly improve the solubility of chlortetracycline, and the solubility also increased with the increase of the added amount. The addition of sodium dipolyphosphate is 20%, and t...

Embodiment 2

[0041] A highly water-soluble chlortetracycline hydrochloride soluble powder comprises the following raw materials in terms of mass percentage: 15% chlortetracycline hydrochloride, 25% cosolvent, and 60% sucrose. Its specific preparation method comprises the following steps:

[0042] S1. Weigh the raw materials according to the proportion;

[0043] S2. Sieving respectively;

[0044] S3. Use a vacuum feeder to suck the raw materials into the mixer, and mix for 25-35 minutes to obtain this product.

Embodiment 3

[0046] A highly water-soluble chlortetracycline hydrochloride soluble powder comprises the following raw materials in terms of mass percentage: 11% chlortetracycline hydrochloride, 30% cosolvent, and 59% sucrose. Its specific preparation method comprises the following steps:

[0047] S1. Weigh the raw materials according to the proportion;

[0048] S2. Sieving respectively;

[0049] S3. Use a vacuum feeder to suck the raw materials into the mixer, and mix for 25-35 minutes to obtain this product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com