Photocatalytic material as well as preparation method and application thereof

A photocatalytic material, potassium bromide technology, applied in the field of photocatalysis, can solve the problem of low hydrogen peroxide efficiency, achieve excellent photocatalytic hydrogen peroxide production performance, stable performance, and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

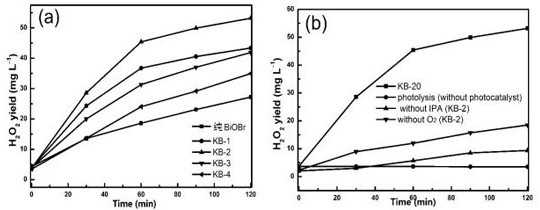

Examples

preparation example Construction

[0036] The embodiment of the present invention also provides a method for preparing a photocatalytic material. The method for preparing a photocatalytic material includes the following steps:

[0037] Weigh bismuth nitrate pentahydrate and potassium bromide (KBr) according to the proportion, add them to the mixture of water and ethylene glycol and mix them evenly to obtain a bismuth oxybromide precursor solution;

[0038] adding potassium hexafluorophosphate to the mixture of ethanol and water for uniform mixing to obtain a potassium hexafluorophosphate solution;

[0039] The potassium hexafluorophosphate solution is added dropwise to the bismuth oxybromide precursor solution and mixed evenly, then transferred to a reaction kettle for hydrothermal reaction, washed and dried after cooling, to obtain the photocatalytic material.

[0040] As another preferred embodiment of the present invention, in the preparation method of the photocatalytic material, the condition of the hydrot...

Embodiment 1

[0049] A photocatalytic material, the specific preparation method is as follows:

[0050] 2.328 g of Bi(NO 3 ) 3 ·5H 2 The mixture of O and 0.571 g of KBr was added to a mixture of 12 mL of water and 28 mL of ethylene glycol and stirred magnetically for 40 min to obtain a bismuth oxybromide precursor solution. At the same time, a certain amount of KPF 6 Add it to the mixed solution of 10 mL ethanol and 10 mL deionized water, stir for 30 min until clear, and obtain potassium hexafluorophosphate solution (KPF in potassium hexafluorophosphate solution 6 The content is 10wt%). Subsequently, the potassium hexafluorophosphate solution was added dropwise to the above-mentioned bismuth oxybromide precursor solution, and after further magnetic stirring for 30 min, it was transferred to the reactor and kept at 110 °C for 10 h, and the reactor was naturally cooled to room temperature , washed with water and ethanol, and dried overnight at 60 °C to obtain KPF 6 The improved BiOBr co...

Embodiment 2

[0053] Compared with Example 1, except KPF in potassium hexafluorophosphate solution 6 The content of is 20wt%, other is identical with embodiment 1. The photocatalytic material prepared in this example is designated as KB-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com