A method for removing oxide layer on nickel-chromium alloy surface

A nickel-chromium alloy, surface oxidation technology, applied in the field of metal surface treatment, can solve the problems of insufficient removal of oxide layer, incomplete peeling of oxide layer, slow cleaning speed, etc., to increase residence time, accelerate drop, and remove speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

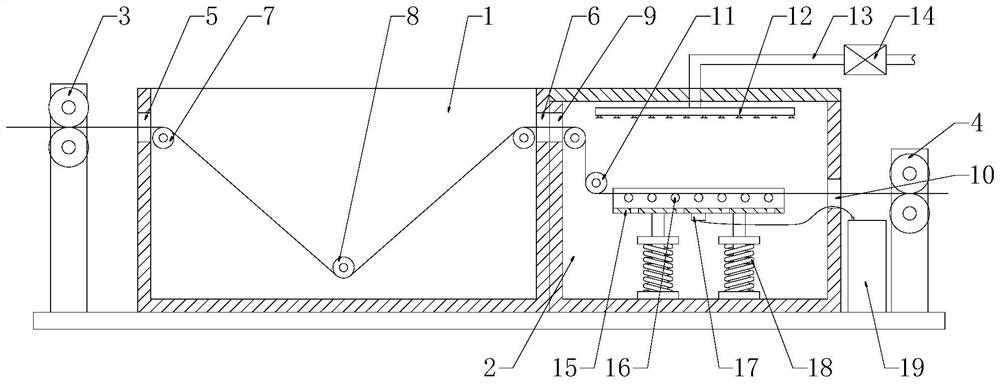

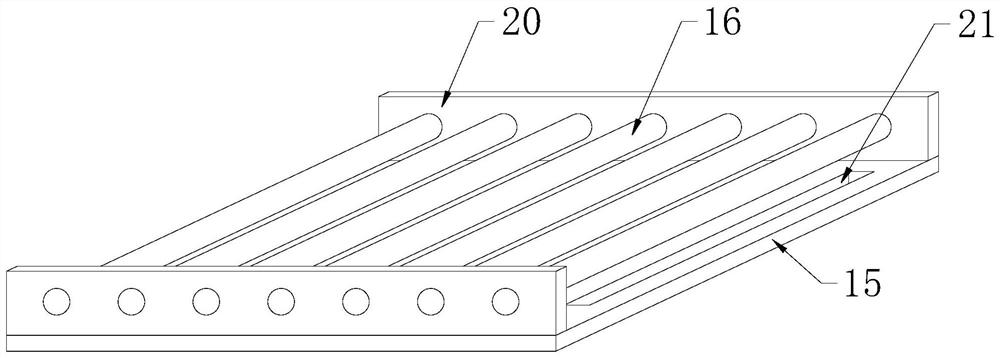

[0038] A device specially used for implementing the method for removing the oxide layer on the surface of the nickel-chromium alloy described in the above-mentioned embodiment 1, comprising a feeding roller 3, a discharging roller 4, a grinding box 1 and an ultrasonic washing box 2, and the feeding roller 3 is located in the grinding chamber. The feeding end of the box 1, the discharge roller 4 is located at the discharging end of the ultrasonic washing box 2, the grinding box 1 is equipped with acid polishing slurry, and the ultrasonic washing box 2 is provided with a spray pipe 12 and an ultrasonic vibration component.

[0039] One side of the grinding box 1 is provided with a first feeding port 5 , the feeding roller 3 is located on one side of the first feeding port 5 , and the other side of the grinding box 1 is provided with a first discharging port 6 . Both the first feeding port 5 and the first discharging port 6 are installed with guide rollers 7 through bearings. A f...

Embodiment 2

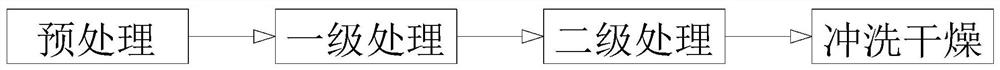

[0051] A method for removing the oxide layer on the surface of a nickel-chromium alloy, using the equipment specially used for removing the oxide layer on the surface of the nickel-chromium alloy of Embodiment 1 to remove the oxide layer, comprising the following method steps:

[0052] S1. Pretreatment: Degrease the surface of the nickel-chromium alloy wire, wash the degreasing wire, and dry it until the surface is free of water after washing; the drying method is 80 ℃ hot air drying; the drying speed of high temperature hot air drying Fast and efficient, which is conducive to improving production efficiency.

[0053] S2. Primary treatment: pass the wire rod through the acid polishing slurry, and use the wire rod to rub against the acid polishing slurry when passing through, thereby rubbing the oxide layer on the surface of the wire rod; the composition of the acid polishing slurry is: hydrochloric acid, water and abrasives, among which, hydrochloric acid, hydrochloric acid, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com