Preparation method and application of catalyst for preparing 2-methylnaphthalene/2, 6-dimethylnaphthalene from synthesis gas and naphthalene through one-step method

A technology of dimethylnaphthalene and catalyst, which is applied in the field of preparation and application of a catalyst for the one-step synthesis of 2-methylnaphthalene/2,6-dimethylnaphthalene from synthesis gas and naphthalene, and can solve the problem of low equilibrium conversion rate of methanol , Catalyst deactivation due to carbon deposits, low conversion rate per pass, etc., to achieve significant economic advantages, low production cost, and high product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention is used for the preparation method of the catalyst of syngas and naphthalene one-step method system 2-methylnaphthalene / 2,6-dimethylnaphthalene, comprises the following steps:

[0037] 1) Co-precipitation method to prepare ZnAlCrOx metal oxide

[0038] Step 1: Dissolve 0.01-0.04mol of zinc nitrate, 0.01-0.04mol of aluminum nitrate and 0.01-0.04mol of chromium nitrate in 120-140mL of deionized water;

[0039] Step 2: add 18g urea to the solution of above-mentioned step 1;

[0040] Step 3: Under continuous stirring, heat up to 90-110°C and keep for 8-12h;

[0041] Step 4: Cool down, leave to age overnight (ie 12h), then centrifuge and wash several times, dry overnight at 100°C, and finally roast at 400-600°C for 4-6h to obtain ZnAlCrOx metal oxide.

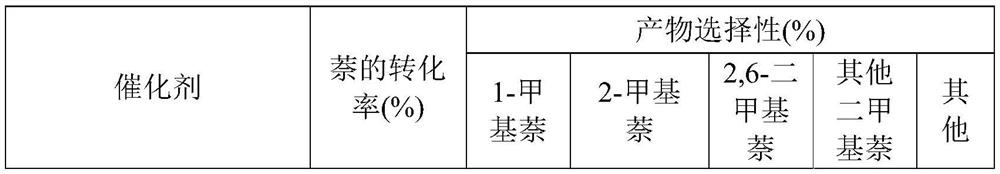

[0042] ZnZrO was simultaneously prepared by the above method x , InZrO x , ZnAlO x , ZnGaO x and other metal oxides.

Embodiment 1

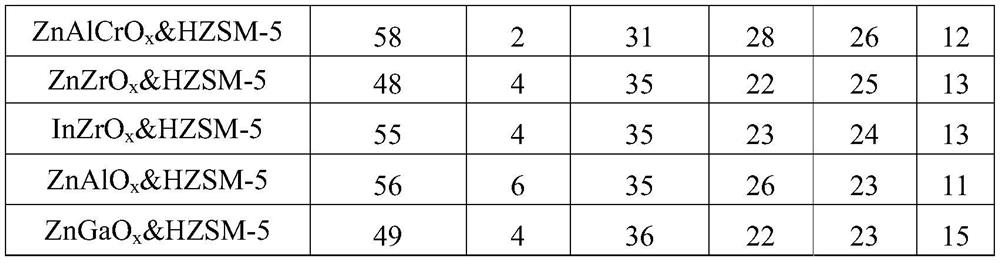

[0056] Example 1ZnAlCrO x &HZSM-5 is specifically prepared through the following process:

[0057] ZnAlCrOx metal oxide is prepared by co-precipitation method, the zinc nitrate of 0.024mol, the aluminum nitrate of 0.008mol and the chromium nitrate of 0.008mol are dissolved in 140mL deionized water; Add 18g urea in the above-mentioned solution; Under continuous stirring, Raise the temperature to 110°C and keep it for 10h; cool down, let stand for aging overnight (ie 12h), then centrifuge and wash several times, dry at 100°C overnight, and finally bake at 500°C for 4h to obtain ZnAlCrOx metal oxide.

[0058] HZSM-5 is a commercial molecular sieve.

[0059] Weigh the above 0.6g of ZnAlCrOx metal oxide and 0.6g of HZSM-5 molecular sieve, and grind them in an agate mortar for 30 minutes to make them evenly mixed. Then put the above-mentioned mixed powder into a tablet machine, and sieve through the tablet to obtain 20-40 mesh ZnAlCrO x &HZSM-5 particles.

Embodiment 2Z

[0060] Example 2ZnZrO x & Preparation of HZSM-5

[0061] ZnZrO x The metal oxide is prepared by co-precipitation method. Dissolve 0.004mol of zinc nitrate and 0.036mol of zirconium nitrate in 140mL of deionized water; add 18g of urea to the above solution; heat up to 110°C under continuous stirring, and keep 10h; cool down, let it stand for aging overnight (ie 12h), then centrifuge and wash several times, dry at 100°C overnight, and finally roast at 500°C for 4h to obtain ZnZrO x Metal oxide.

[0062] HZSM-5 is the same as embodiment 1.

[0063] Weigh the above 0.6g of ZnZrO x The metal oxide and 0.6g of HZSM-5 molecular sieve were ground in an agate mortar for 30 minutes to make them evenly mixed. Then put the above mixed powder into the tablet machine, and sieve it through the tablet to obtain 20-40 mesh ZnZrO x &HZSM-5 particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com