Vanadium-phosphorus-oxygen low-temperature denitration catalyst and molding preparation method thereof

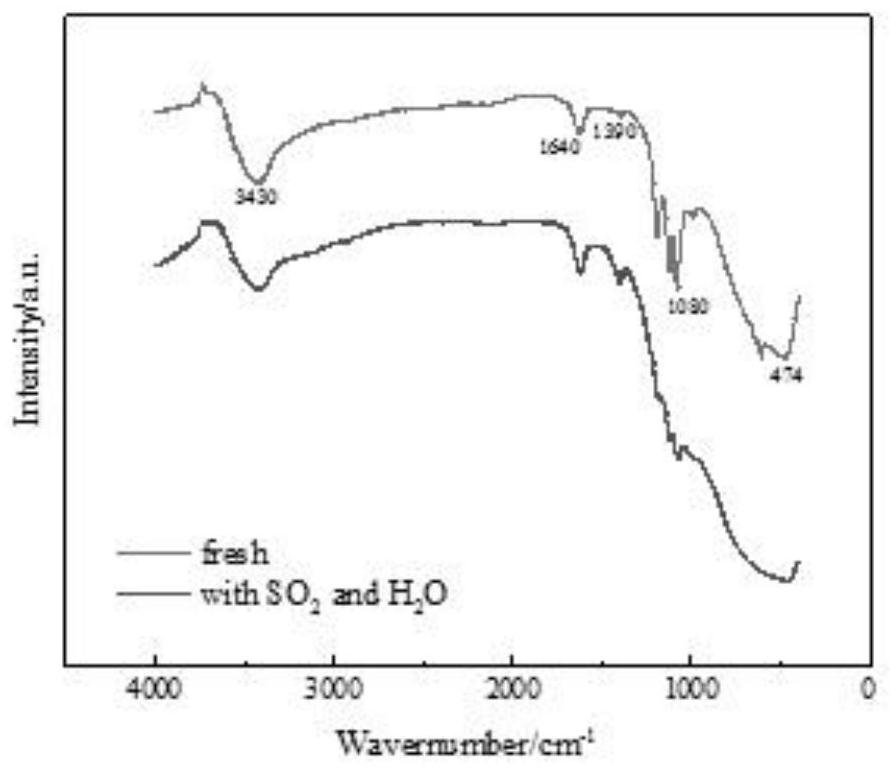

A low-temperature denitrification, vanadium phosphorus oxygen technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of no effective inhibition of ammonium sulfate deposition, no fundamental improvement in anti-sulfur and water resistance, etc. problems, to achieve high and low temperature denitrification activity, low cost, strong anti-sulfur and water-resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

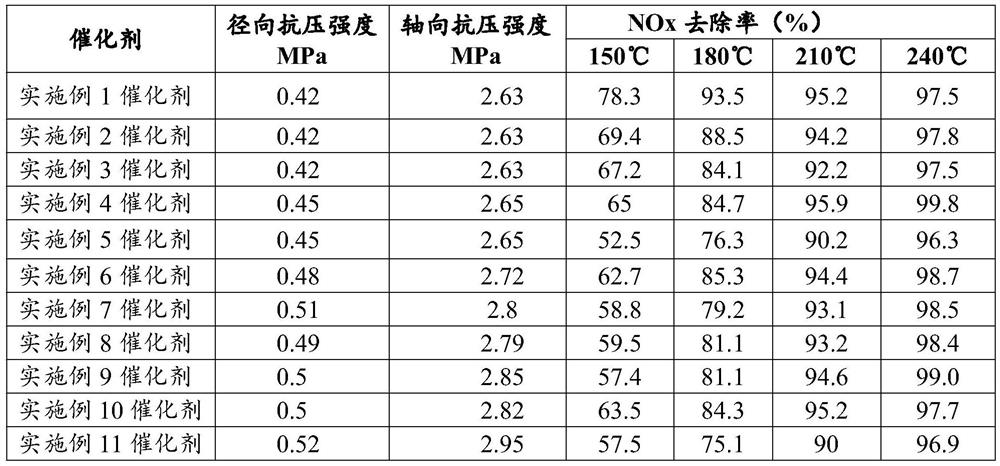

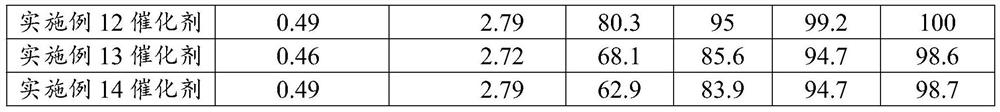

Examples

Embodiment 1

[0033](1) Preparation of active components

[0034]The oxalic acid is mixed with a solution having a concentration of 15%, and a metcanavanate is added to a proportion of ammonium titrate. After stirring at 25 ° C, it is added to the mixed solution, hydrochloric acid and polyethylene glycol, wherein the metadavate and oxalic acid are added. The molar ratio is 1: 2, the molar ratio of metadavadate and phosphoric acid is 1: 5, the molar ratio of metadavadate and HCl is 1: 4, and the mass ratio of metadavadate and PEG is 1: 0.005. Next, the mixed solution was stirred at a temperature of 25 ° C for 2 h, then heated at 70 ° C, and the active component VPO gel was formed, and the VPO gel density was 1.231 g / cm.3.

[0035](2) carrier preparation

[0036]The specific surface area is greater than 300m2 / g of titanium white powder and specific surface area are 90 ~ 110m2The titanium white powder of / g is mixed in a ratio of 1: 9, and monoethanolamine, lactic acid, carboxymethylcellulose (CMC), poly...

Embodiment 2

[0041](1) Preparation of active components

[0042]The oxalic acid is mixed with a solution having a concentration of 15%, and a metcanavanate is added to a proportion of ammonium titrate. After stirring at 25 ° C, it is added to the mixed solution, hydrochloric acid and polyethylene glycol, wherein the metadavate and oxalic acid are added. The molar ratio is 1: 2, the molar ratio of metadavadate and phosphoric acid is 1: 5, the molar ratio of metadavadate and HCl is 1: 4, and the mass ratio of metadavadate and PEG is 1: 0.005. The mixed solution was then stirred at a temperature of 25 ° C for 2 h, then heated at 70 ° C, and the active component VPO gel was formed, and the VPO gel density was 1.231 g / cm3.

[0043](2) carrier preparation

[0044]The specific surface area is greater than 300m2 / g of titanium white powder and specific surface area are 90 ~ 110m2The titanium white powder of / g is mixed by mass ratio of 2: 8, and monoethanolamine, lactic acid, carboxymethylcellulose (CMC), pol...

Embodiment 3

[0049](1) Preparation of active components

[0050]The oxalic acid is mixed with a solution having a concentration of 15%, and a metcanavanate is added to a proportion of ammonium titrate. After stirring at 25 ° C, it is added to the mixed solution, hydrochloric acid and polyethylene glycol, wherein the metadavate and oxalic acid are added. The molar ratio is 1: 2, the molar ratio of metadavadate and phosphoric acid is 1: 5, the molar ratio of metadavadate and HCl is 1: 4, and the mass ratio of metadavadate and PEG is 1: 0.005. The mixed solution was then stirred at a temperature of 25 ° C for 2 h, then heated at 70 ° C, and the active component VPO gel was formed, and the VPO gel density was 1.231 g / cm3.

[0051](2) carrier preparation

[0052]The specific surface area is greater than 300m2 / g of titanium white powder and specific surface area are 90 ~ 110m2The titanium white powder of / g is mixed in a ratio of 3: 7, and monoethanolamine, lactic acid, carboxymethylcellulose (CMC), polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com