Method for producing alkyl peroxycarboxylate based on titanium silicalite molecular sieve composite catalyst

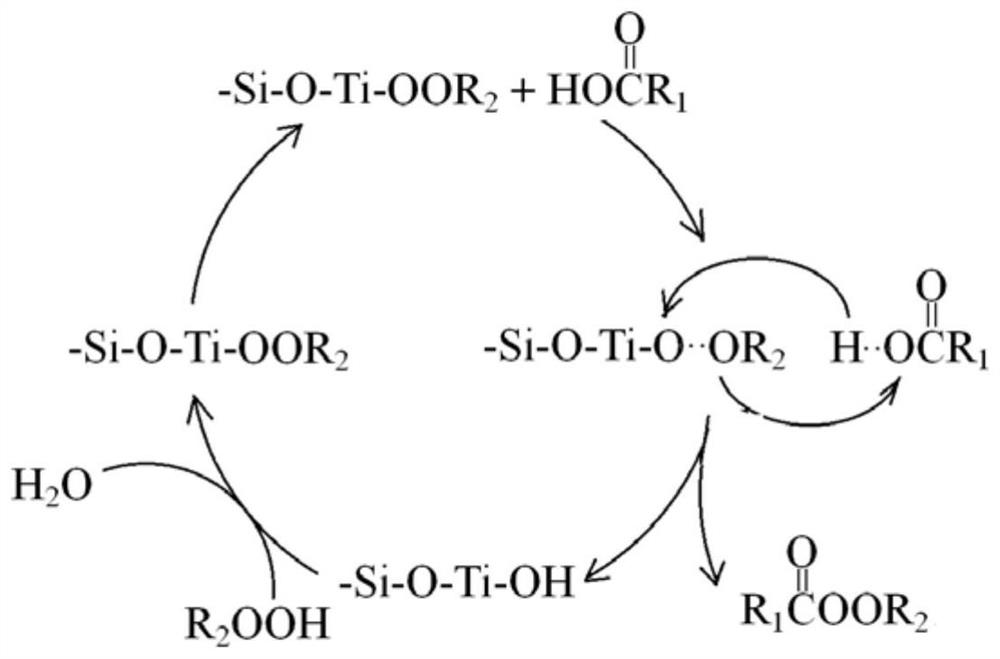

A technology for peroxidizing alkyl carboxylate and titanium-silicon molecular sieve is applied in molecular sieve catalysts, peroxy compound preparation, chemical instruments and methods, etc. It can solve the problems of expensive acid chloride and corrosion, avoid corrosive substances and save chemical The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

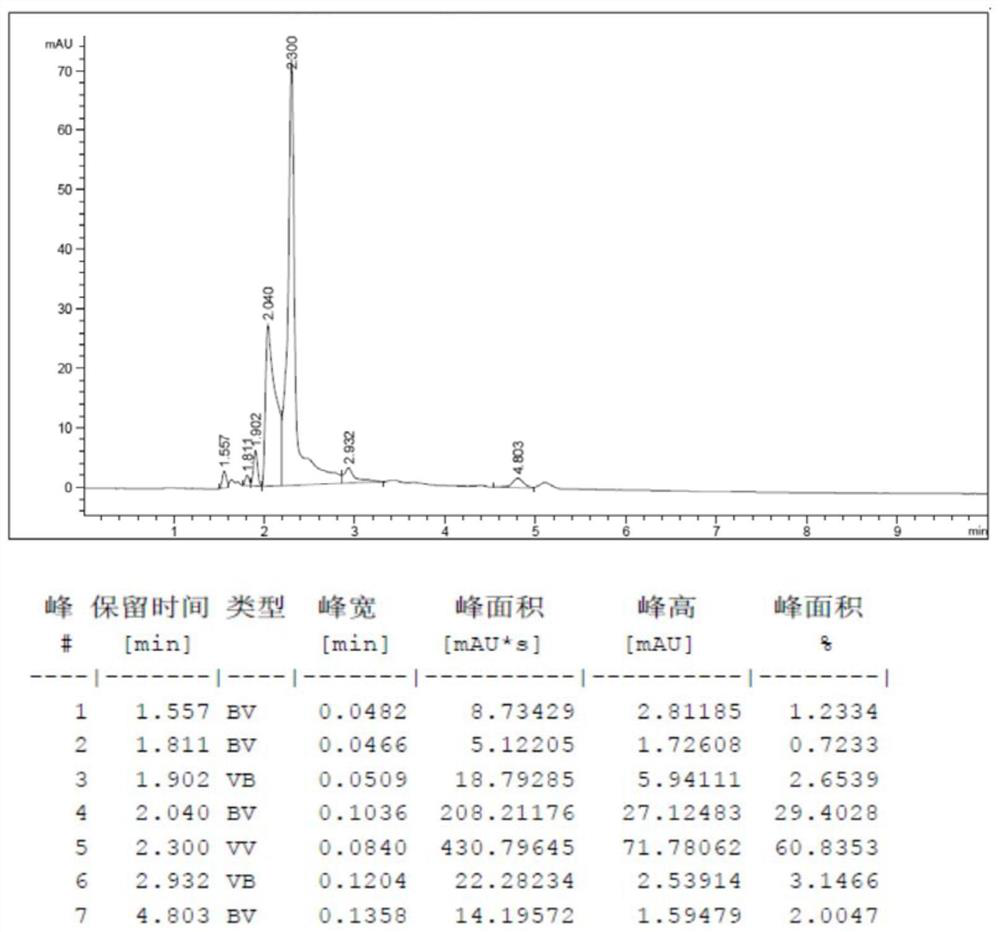

[0052] In a 500ml three-necked flask, 20ml of isododecane was added, 30g of tert-butyl hydroperoxide with a purity of 99.5wt.%, 57.3g of neodecanoic acid, and 20g of composite catalyst A were added. The mixture was stirred at 0°C for 6 hours. The composite catalyst A was recovered by filtration with a sand core filter to obtain 74.5 g of a solution containing tert-butyl peroxyneodecanoate. Based on the mass of input raw materials, the yield is 78%. According to gas chromatography analysis, the solution contained 60.8% of tert-butyl peroxyneodecanoate. See figure 1 .

[0053] Gas chromatography experimental conditions: 2m×φ3mm stainless steel column; stationary phase: 60-80 mesh white carrier coated with 5% SE-30; column temperature 40°C, vaporization temperature 90°C, detector FID temperature 110°C.

Embodiment 2

[0055] In a 500ml three-necked flask, 50ml of isododecane was added, 30g of tert-butyl hydroperoxide with a purity of 99.5wt.%, 57.3g of neodecanoic acid, and 15g of composite catalyst B were added. The mixture was stirred at 10°C for 6 hours. The composite catalyst B was recovered by filtration with a sand core filter to obtain 112.4 g of a solution containing tert-butyl peroxyneodecanoate, with a yield of 86% based on the mass of the input raw materials. According to gas chromatography analysis, the solution contained 19.0% tert-butyl peroxyneodecanoate.

Embodiment 3

[0057] In a 500ml three-necked flask, 100ml of toluene was added, 30g of tert-butyl hydroperoxide with a purity of 99.5wt.%, 57.3g of neodecanoic acid, and 15g of composite catalyst C were added. The reaction mixture was stirred at 20°C for 4 hours. The composite catalyst C was recovered by filtration with a sand core filter to obtain 161.6 g of a solution containing tert-butyl peroxyneodecanoate, with a yield of 89% based on the mass of the input raw materials. According to gas chromatography analysis, the solution contained 17.5% of tert-butyl peroxyneodecanoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com