High-performance polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, high-performance technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of destroying the adhesive strength of the colloid, affecting the life of wearable devices, etc., and achieve excellent reactivity Effective with perspiration resistance, good oil resistance, avoidance of colloid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

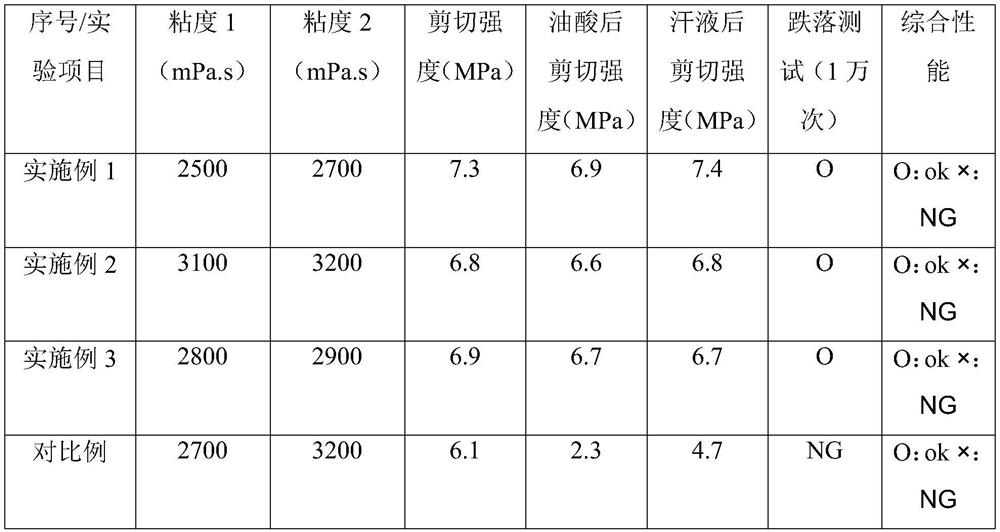

Embodiment 1

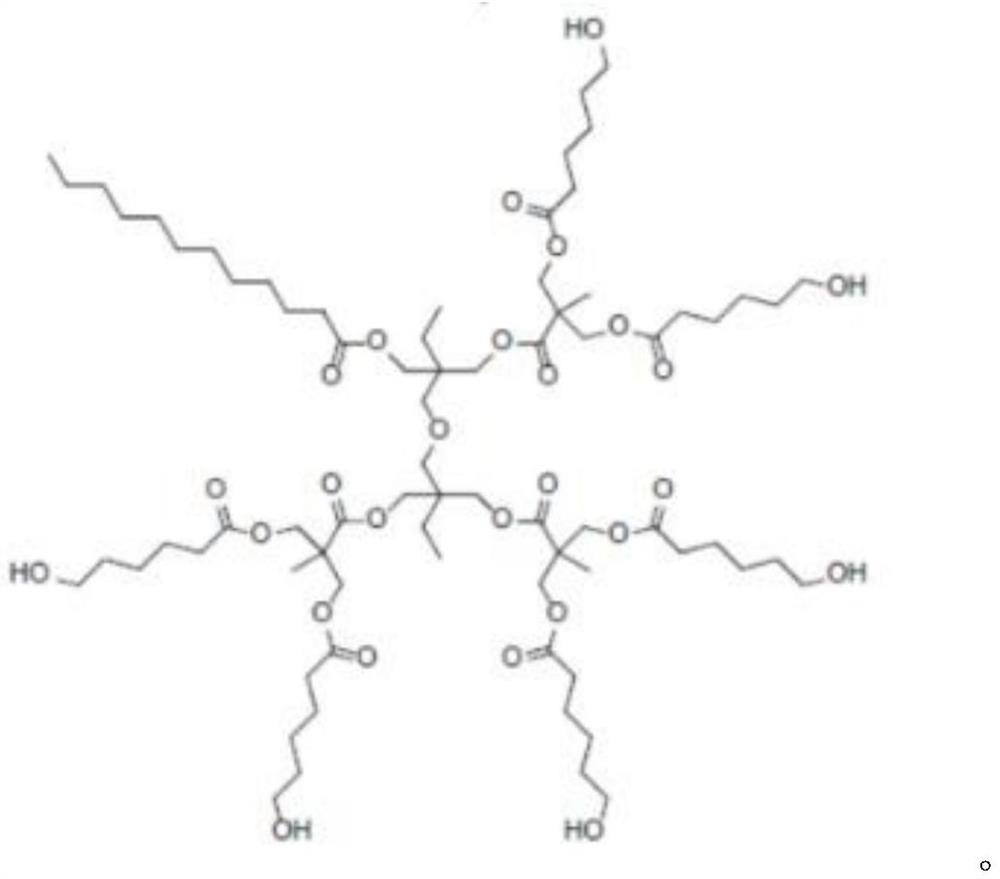

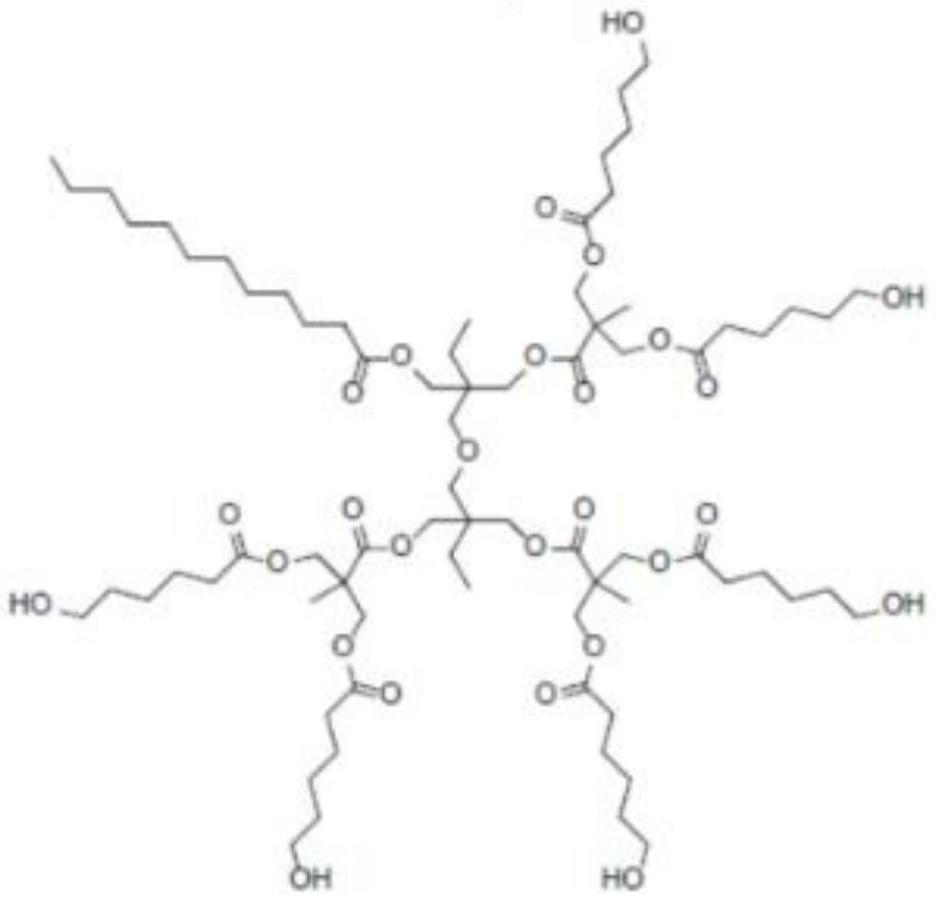

[0027] (1) 20 parts of adipic acid-based polyester diol with a molecular weight of 2000, 30 parts of polycarbonate diol with a molecular weight of 4000, 10 parts of hydroxyl-terminated polybutadiene acrylonitrile, and a multi-arm star with a molecular weight of 715 Add 1 part of hydroxyl-terminated polyester polyol to the reaction kettle, stir and mix evenly, heat up to 115-125°C, and dehydrate for 2 hours under the condition of vacuum degree ≤0.95MPa;

[0028] (2) Cool down to 90-100°C, add 10 parts of diphenylmethane diisocyanate, and react for 1.5h at a temperature of 115-125°C;

[0029] (3) Add 0.05 parts of triethylenediamine, and continue to react for 0.5h at a temperature of 115-125°C and a vacuum degree of ≤0.95MPa;

[0030] (4) Quickly discharge the material under nitrogen protection, and package it in an aluminum foil bag.

Embodiment 2

[0032] (1) 40 parts of polyethylene glycol phthalate diols with a molecular weight of 2000, 40 parts of polycarbonate diols with a molecular weight of 4000, 30 parts of hydroxyl-terminated polybutadiene acrylonitrile, and a molecular weight of 1854 Add 5 parts of multi-arm star-shaped hydroxyl-terminated polyester polyol into the reaction kettle, stir and mix evenly, heat up to 115-125°C, and dehydrate for 2 hours under the condition of vacuum degree ≤0.95MPa;

[0033] (2) Cool down to 90-100°C, add 20 parts of diphenylmethane diisocyanate, and react for 1.5h at a temperature of 115-125°C;

[0034] (3) Add 0.05 part of bismorpholino diethyl ether, 0.05 part of stannous octoate, and continue to react for 0.5 h at a temperature of 115-125 °C and a vacuum degree of ≤0.95 MPa;

[0035] (4) Quickly discharge the material under nitrogen protection, and package it in an aluminum foil bag.

Embodiment 3

[0037] (1) 20 parts of polyethylene glycol phthalate diols with a molecular weight of 3000, 40 parts of polycarbonate diols with a molecular weight of 2500, 20 parts of hydroxyl-terminated polybutadiene acrylonitrile, and a molecular weight of 1000 Add 3 parts of multi-arm star-shaped hydroxyl-terminated polyester polyol into the reaction kettle, stir and mix evenly, heat up to 115-125°C, and dehydrate for 2 hours under the condition of vacuum degree ≤0.95MPa;

[0038] (2) Cool down to 90-100°C, add 14 parts of diphenylmethane diisocyanate, and react for 1.5h at a temperature of 115-125°C;

[0039] (3) Add 0.06 parts of triethanolamine, and continue to react for 0.5 h at a temperature of 115-125 °C and a vacuum degree of ≤0.95 MPa;

[0040] (4) Quickly discharge the material under nitrogen protection, and package it in an aluminum foil bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com