Preparation method of cobalt diselenide/iron oxyhydroxide composite material with nano petal-shaped structure

A technology of iron oxyhydroxide and cobalt diselenide, applied in electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of rapid desorption of unfavorable products, limited catalytic activity, lack of sufficient room for improvement of catalytic activity, etc., and achieve high yield , enhance catalytic activity, optimize the effect of local electronic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

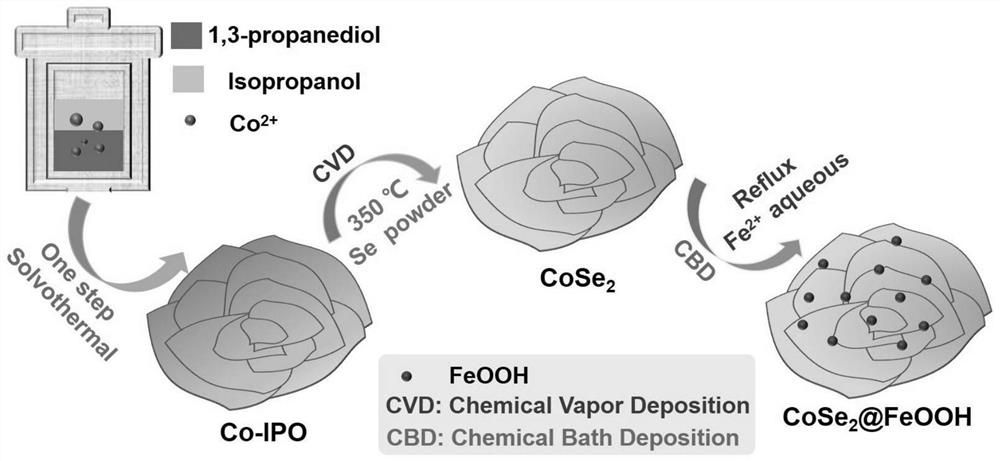

[0061] A kind of preparation of the cobalt diselenide / iron oxyhydroxide composite material of nano petal-like structure, specifically comprises the following steps:

[0062] Preparation of S1 cobalt-containing precursor:

[0063] (1) Mix 40ml of isopropanol and 20ml of 1,3-propanediol to obtain a solvent;

[0064] (2) Add 0.22g of cobalt nitrate to the solvent in step (1), and ultrasonically disperse until the metal salt is completely dissolved to obtain a 0.02mol / L cobalt salt solution;

[0065] (3) Without adding any other organic additives, transfer the cobalt salt solution in step (1) to a 180ml hydrothermal reaction kettle, tightly seal it, transfer the hydrothermal reaction kettle to an oven, and turn on the heating. Seal and heat up to 150°C for reaction, and react for 10 hours. After the reaction, the precipitate is collected by vacuum filtration, the filter cake is repeatedly washed with methanol, and freeze-dried to obtain a cobalt-containing precursor powder, which...

Embodiment 2

[0071] A kind of preparation of the cobalt diselenide / iron oxyhydroxide composite material of nano petal-like structure, specifically comprises the following steps:

[0072] Preparation of S1 cobalt-containing precursor:

[0073] (1) Mix 1,3-propanediol with 160ml of isopropanol and 20ml to obtain a solvent;

[0074] (2) Take 5.12g of cobalt acetylacetonate and add it to the solvent in step (1), and ultrasonically disperse until the metal salt is completely dissolved to obtain a 0.08mol / L cobalt salt solution;

[0075] (3) Without adding any other organic additives, transfer the cobalt salt solution in step (1) to a 450ml hydrothermal reaction kettle, seal it tightly, transfer the hydrothermal reaction kettle to an oven, and turn on the heating. Seal and heat up to 180°C for reaction, and react for 15 hours. After the reaction, the precipitate is collected by vacuum filtration, the filter cake is repeatedly washed with ethanol, and vacuum-dried at 80°C to obtain a cobalt-cont...

Embodiment 3

[0081] A kind of preparation of the cobalt diselenide / iron oxyhydroxide composite material of nano petal-like structure, specifically comprises the following steps:

[0082] Preparation of S1 cobalt-containing precursor:

[0083] (1) Mix 80ml of isopropanol and 20ml of 1,3-propanediol to obtain a solvent;

[0084] (2) Get 0.7g cobalt acetate and add the solvent in step (1), and ultrasonically disperse until the metal salt is completely dissolved to obtain a 0.04mol / L cobalt salt solution;

[0085] (3) In the case of not adding any other organic additives, the cobalt salt solution in step (1) is transferred to a 270ml polytetrafluoroethylene-lined hydrothermal reaction kettle, strictly sealed, and the hydrothermal reaction kettle is transferred to In the oven, turn on the heating, seal and heat up to 160°C for reaction, and react for 12 hours. After the reaction, the precipitate is collected by filtration under reduced pressure, the filter cake is washed repeatedly with washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com