Waterproof antibacterial cooling functional fiber and preparation method thereof

A technology of functional fibers and functional layers, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of easy inactivation or loss of antibacterial active ingredients, single function of antibacterial fibers, poor skin feeling of antibacterial fibers, etc. The preparation method is simple and feasible, the waterproof effect is good, and the antibacterial ability is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of plant extract microcapsules

[0025] The core material of the plant extract microcapsules in this example is composed of aloe vera particles, green tea particles, andrographis paniculata, astragalus particles, isatidis particles, and Gastrodia elata particles.

[0026] In terms of mass fraction, take 10 parts of sodium alginate solution, add 5 parts of core material to the sodium alginate solution, and mix evenly; and mix the above-mentioned mixed solution with 8 parts of chitosan and 5 parts of calcium chloride for blending in the solution, stir evenly and solidify, filter out the supernatant, and dry the filter residue to obtain plant extract microcapsules.

[0027] 2. Preparation of waterproof, antibacterial and cooling functional fibers

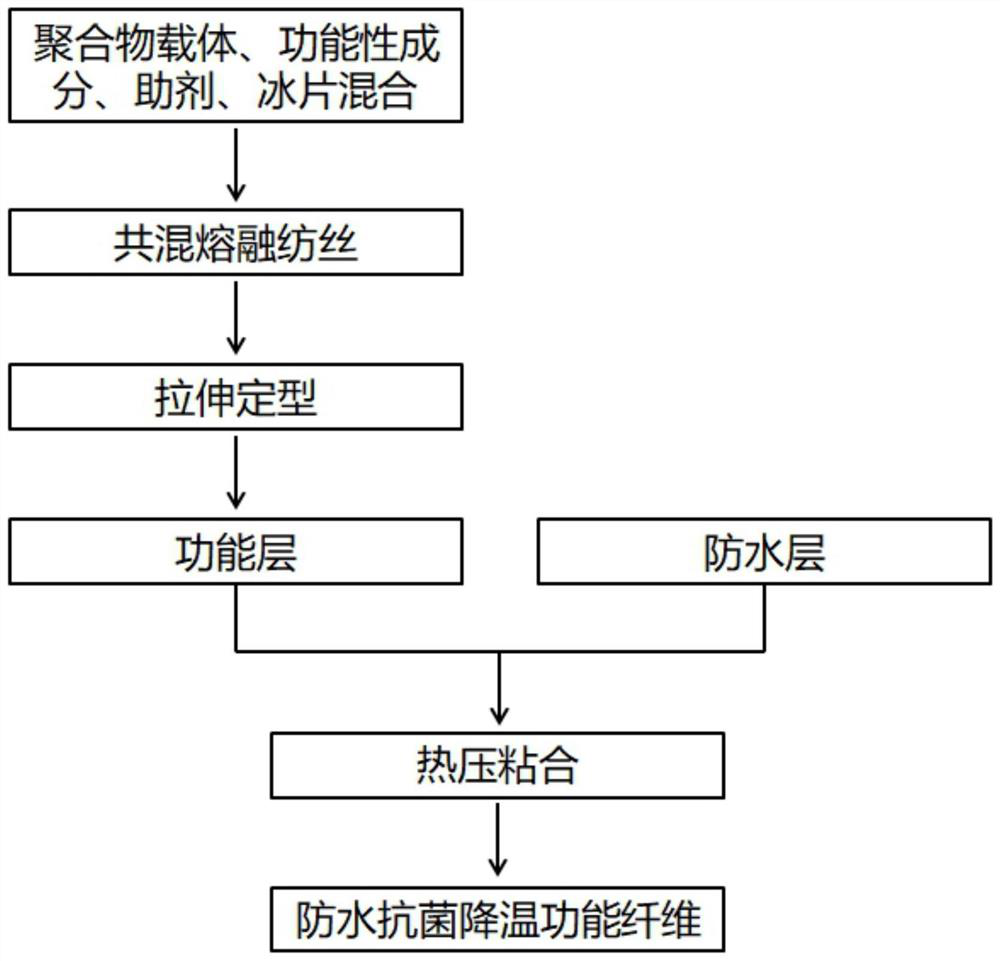

[0028] Such as figure 1 shown, including the following steps:

[0029] (1) After mixing 300 parts of chitosan, 10 parts of plant extract microcapsules, 5 parts of glycerin, and 1 part of borneol by weight, carr...

Embodiment 2

[0032] 1. Preparation of nano-silver microcapsules

[0033] The core material of the nano-silver microcapsules in this embodiment is nano-silver ions.

[0034] In terms of mass fraction, take 15 parts of sodium alginate solution, add 10 parts of core material to the sodium alginate solution, and mix evenly; and mix the above-mentioned mixed solution with 10 parts of chitosan and 6 parts of calcium chloride for blending In the solution, stir evenly and solidify, filter out the supernatant, and dry the filter residue to obtain nano-silver microcapsules.

[0035] 2. Preparation of waterproof, antibacterial and cooling functional fibers

[0036] Such as figure 1 shown, including the following steps:

[0037] (1) After mixing 400 parts of polylactic acid, 20 parts of nano-silver microcapsules, 10 parts of sodium alginate, and 2 parts of borneol according to the weight ratio, carry out blending and melt spinning in a screw extruder, and then stretch After shaping, the functional...

Embodiment 3

[0040] 1. Preparation of plant extract microcapsules

[0041] The core material of the plant extract microcapsules in this example is composed of aloe vera particles, green tea particles, and andrographis paniculata particles.

[0042] In terms of mass fraction, take 20 parts of sodium alginate solution, add 15 parts of core material to the sodium alginate solution, and mix well; and mix the above-mentioned mixed solution with 12 parts of chitosan and 7 parts of calcium chloride in the solution, stir evenly and solidify, filter out the supernatant, and dry the filter residue to obtain plant extract microcapsules.

[0043] 2. Preparation of waterproof, antibacterial and cooling functional fibers

[0044] Such as figure 1 shown, including the following steps:

[0045] (1) After mixing 500 parts of polylactic acid-glycolic acid copolymer, 30 parts of plant extract microcapsules, 15 parts of glycerin, and 3 parts of borneol in parts by weight, carry out blending and melt spinni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com