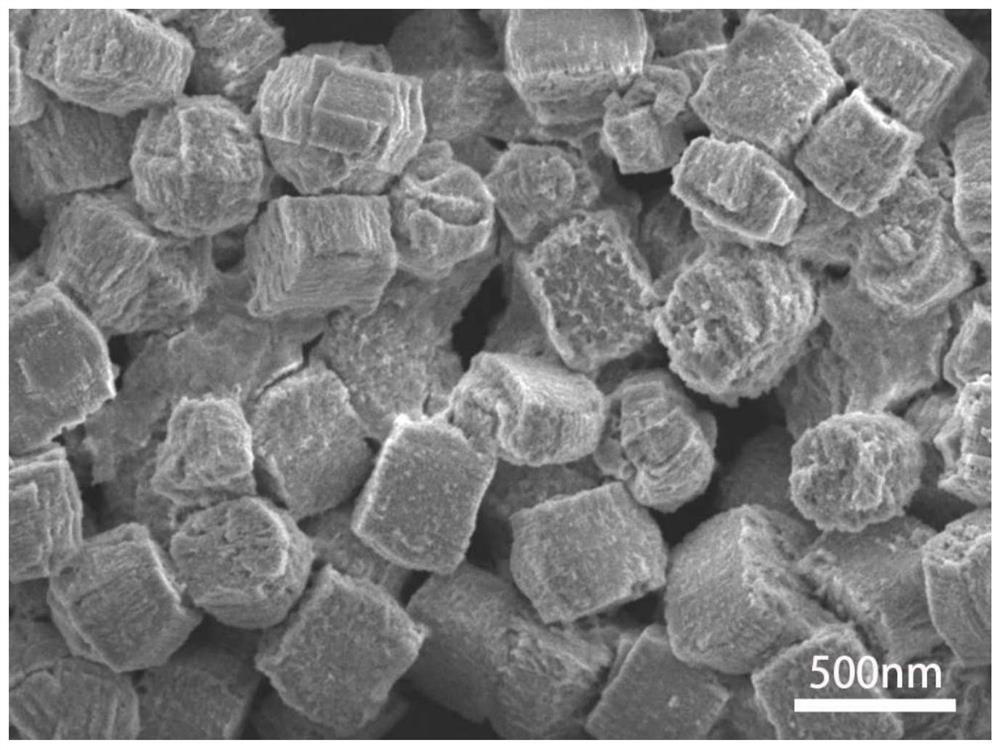

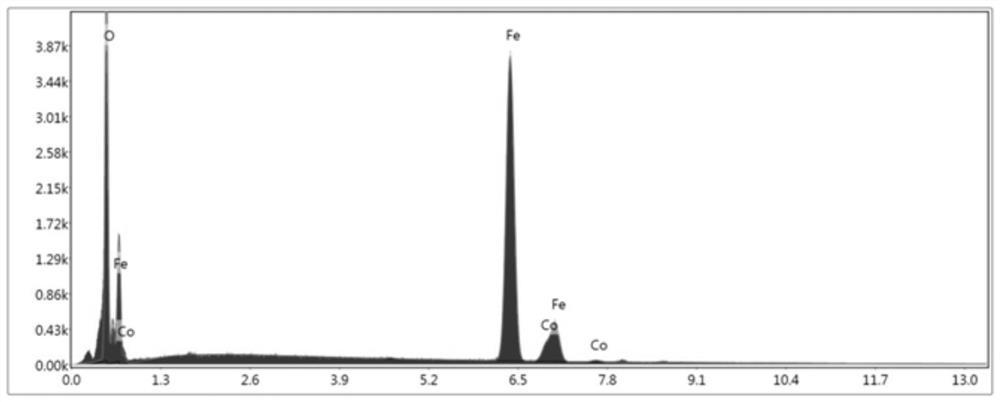

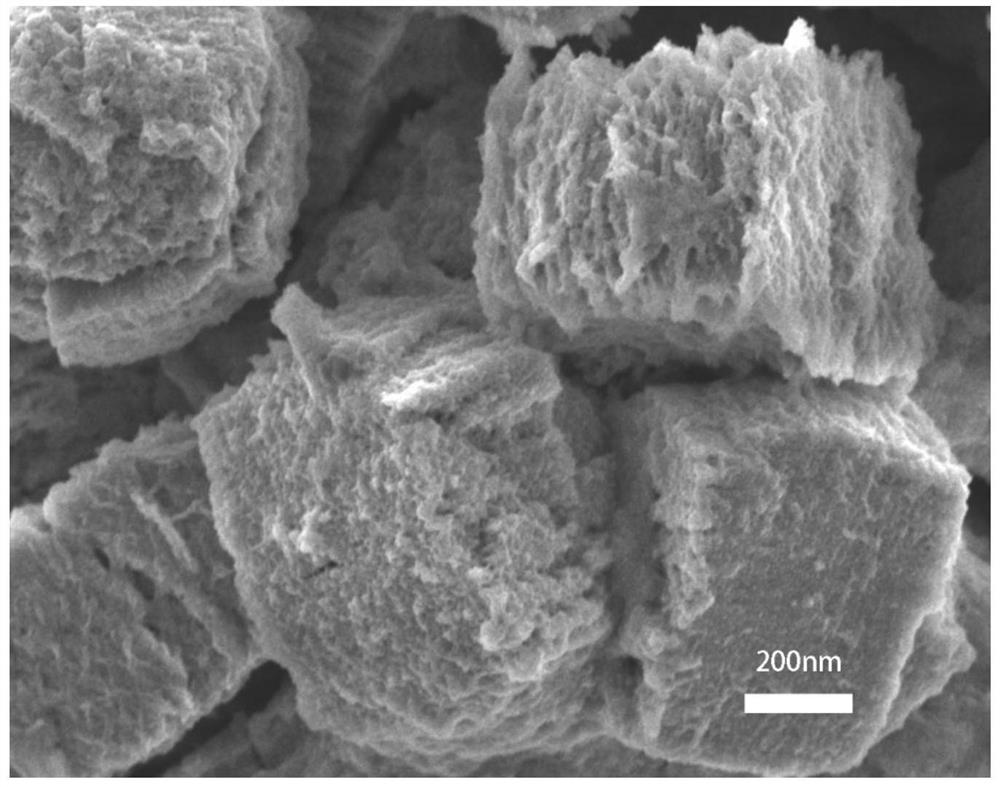

Porous layered CoFe2O4/C nano composite material and preparation method thereof

A nano-composite material, cofe2o4 technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of lithium-ion battery capacity decline, affecting battery cycle performance, and damage to material integrity, so as to facilitate scale production, reduce volume expansion, and reduce the effect of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A porous layered CoFe 2 o 4 The preparation method of / C nanocomposite material, comprises the following steps:

[0032] Step 1: Dissolve 0.4g of ferric chloride hexahydrate, 0.18g of cobalt chloride hexahydrate and 0.5g of hexamethyltetramine in 20ml of ethylene glycol, stir magnetically for 30 minutes to fully dissolve, and configure A solution;

[0033] Step 2: Dissolve 0.5g of sodium citrate in 20ml of ethylene glycol and magnetically stir in a water bath at 60°C for 30 minutes to fully dissolve it and configure it into solution B;

[0034] Step 3: Slowly pour solution B into solution A and continue magnetic stirring for 30 minutes to obtain mixed solution C;

[0035] Step 4, transfer the mixed solution C to an 80ml reaction kettle, set the temperature of the incubator at 160°C to keep the reaction for 6h, wash thoroughly with water and ethanol, and then obtain the initial product of the reaction by a one-pot method;

[0036] Step 5, transfer the initial product...

Embodiment 2

[0038] A porous layered CoFe 2 o 4 The preparation method of / C nanocomposite material, comprises the following steps:

[0039] Step 1: Dissolve 0.4g of ferric chloride hexahydrate, 0.18g of cobalt chloride hexahydrate and 1g of hexamethyltetramine in 20ml of ethylene glycol, stir magnetically for 30min to fully dissolve, and prepare solution A ;

[0040] Step 2: Dissolve 0.5g of sodium citrate in 20ml of ethylene glycol and magnetically stir in a water bath at 60°C for 30 minutes to fully dissolve it and configure it into solution B;

[0041] Step 3: Slowly pour solution B into solution A and continue magnetic stirring for 30 minutes to obtain mixed solution C;

[0042] Step 4, transfer the mixed solution C to an 80ml reaction kettle, set the temperature of the incubator at 160°C to keep the reaction for 6h, wash thoroughly with water and ethanol, and then obtain the initial product of the reaction by a one-pot method;

[0043] Step 5, transfer the initial product of the ...

Embodiment 3

[0045] A porous layered CoFe 2 o 4 The preparation method of / C nanocomposite material, comprises the following steps:

[0046] Step 1: Dissolve 0.2g of ferric chloride hexahydrate, 0.09g of cobalt chloride hexahydrate and 1g of hexamethyltetramine in 20ml of ethylene glycol, stir magnetically for 30 minutes to fully dissolve, and prepare solution A ;

[0047] Step 2: Dissolve 0.5g of sodium citrate in 20ml of ethylene glycol and magnetically stir in a water bath at 60°C for 30 minutes to fully dissolve it and configure it into solution B;

[0048] Step 3: Slowly pour solution B into solution A and continue magnetic stirring for 30 minutes to obtain mixed solution C;

[0049] Step 4, transfer the mixed solution C to an 80ml reaction kettle, set the temperature of the incubator at 160°C to keep the reaction for 6h, wash thoroughly with water and ethanol, and then obtain the initial product of the reaction by a one-pot method;

[0050] Step 5, transfer the initial product of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com