A kind of nano catalyst and its preparation method and application

A nano-catalyst and nano-particle technology, which is used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of inability to achieve large-scale applications, low catalytic activity, etc. The effect of high catalytic activity and conversion rate, good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

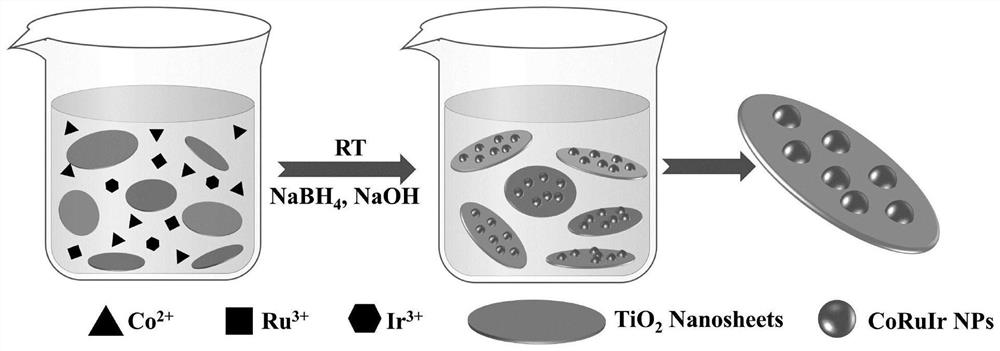

[0026] The embodiment of the present invention also provides a preparation method of the above nanocatalyst, the preparation method of the nanocatalyst includes the following steps: using titanium dioxide aqueous solution, CoCl 2 Aqueous solution, RuCl 3 Aqueous solution, IrCl 3 Aqueous solution is used as raw material, after adding sodium hydroxide (NaOH) aqueous solution and sodium borohydride (NaBH 4 ) aqueous solution to carry out the reduction reaction to obtain the nano-catalyst.

[0027] As another preferred embodiment of the present invention, the preparation method of the nanocatalyst comprises the following steps:

[0028] Titanium dioxide, CoCl 2 、RuCl 3 , IrCl 3 Add water separately to prepare titanium dioxide aqueous solution, CoCl 2 Aqueous solution, RuCl3 Aqueous solution, IrCl 3 aqueous solution;

[0029] CoCl 2 Aqueous solution, RuCl 3 Aqueous solution, IrCl 3 The aqueous solution is added to the titanium dioxide aqueous solution and mixed uniformly...

Embodiment 1

[0053] A kind of nano catalyst, specifically a kind of titanium dioxide supported CoRuIr nano catalyst, its preparation method is as follows figure 1 As shown, it specifically includes the following steps:

[0054] Step 1. Prepare 15 mL of titanium dioxide aqueous solution with a concentration of 2 mg / mL, specifically adding an appropriate amount of titanium dioxide into water and ultrasonically treating it for 60 minutes to obtain a uniformly dispersed titanium dioxide aqueous solution;

[0055] Step 2, the total amount of 0.1mmol of CoCl 2 、RuCl 3 , IrCl 3 (CoCl 2 : RuCl 3 : IrCl 3 The molar ratio is 6:2:2), and it is added into the titanium dioxide aqueous solution in step 1 in the form of an aqueous solution, and after continuing to stir for 10 minutes, a mixed solution is obtained;

[0056] Step 3: Dissolve 412 mg of NaOH and 30 mg of sodium borohydride in 1 mL of distilled water, then add it to the mixed solution in step 2, and stir at 25° C. for 15 min to perform ...

Embodiment 2

[0058] A kind of nano catalyst, specifically a kind of titanium dioxide supported CoRuIr nano catalyst, its preparation method comprises the following steps:

[0059] Step 1, preparing 15 mL of titanium dioxide aqueous solution with a concentration of 2 mg / mL, specifically, adding an appropriate amount of titanium dioxide into water and ultrasonically treating it for 30 minutes to obtain a uniformly dispersed titanium dioxide aqueous solution;

[0060] Step 2, the total amount of 0.05mmol of CoCl 2 、RuCl 3 , IrCl 3 (CoCl 2 : RuCl 3 : IrCl 3 The molar ratio is 6:2:2), and it is added into the titanium dioxide aqueous solution in step 1 in the form of an aqueous solution, and after continuing to stir for 10 minutes, a mixed solution is obtained;

[0061] Step 3: Dissolve 412 mg of NaOH and 20 mg of sodium borohydride in 1 mL of distilled water, then add it to the mixed solution in step 2, and stir at 25° C. for 15 min to perform a reduction reaction to obtain a titanium dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com