The preparation method of lithium sulfide

A technology of lithium sulfide and lithium thiosulfate, applied in the directions of alkali metal sulfide/polysulfide, electrochemical generator, electrical components, etc., can solve the problems of high temperature and high energy consumption, and meet the requirements of safe operation and energy consumption. Low, batch production stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of lithium sulfide of the present invention, its steps are as follows successively:

[0020] a. Grinding and mixing: mix and grind the sulfur source and the lithium source, add hydrazine hydrate while grinding, finish the grinding after adding, and obtain the reaction material; wherein, the sulfur source is sulfur powder, lithium thiosulfate or lithium sulfite ; The lithium source is lithium hydroxide, lithium thiosulfate or lithium sulfite;

[0021] b. Vacuum defoaming: put the reaction materials into a vacuum defoaming bucket, and vacuumize. After the bubbles are eliminated, keep the vacuum state for 1 to 4 hours, and then change the air pressure to normal pressure to obtain a lithium sulfide solution;

[0022] c. Drying: Lithium sulfide solution is dried to obtain lithium sulfide.

[0023] The method of the present invention adopts mixed grinding of sulfur source and lithium source to ensure that the raw materials can be fully contacted, and r...

Embodiment 1

[0038] Mole ratio Li 2 O:S:N 2 h 4 ·H 2Weigh lithium hydroxide monohydrate, sulfur powder and hydrazine hydrate in a ratio of O→1:2:4, mix lithium hydroxide monohydrate and sulfur powder and grind evenly, then slowly add hydrazine hydrate into the mixed powder, Grind while adding until the hydrazine hydrate is added completely. The obtained reaction material is put into a vacuum defoaming barrel, vacuumed to below 0.1MPa, and the reaction is continued until the bubbles are no longer generated, and then the vacuum state is maintained for 1 hour, and the valve of the vacuum defoaming barrel is opened until the air pressure reaches normal pressure. Transfer to a vacuum freeze dryer, carry out vacuum freeze drying at a low temperature of -50°C and a pressure below 100 Pa for 4 hours, vacuum cap the dried material and take it out to obtain the lithium sulfide product YP-1.

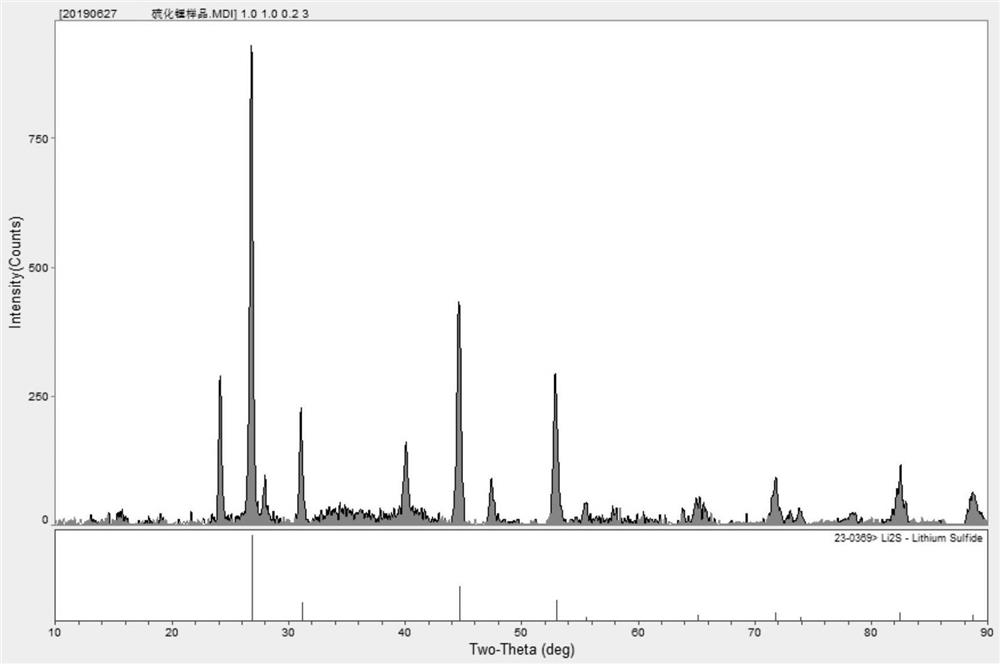

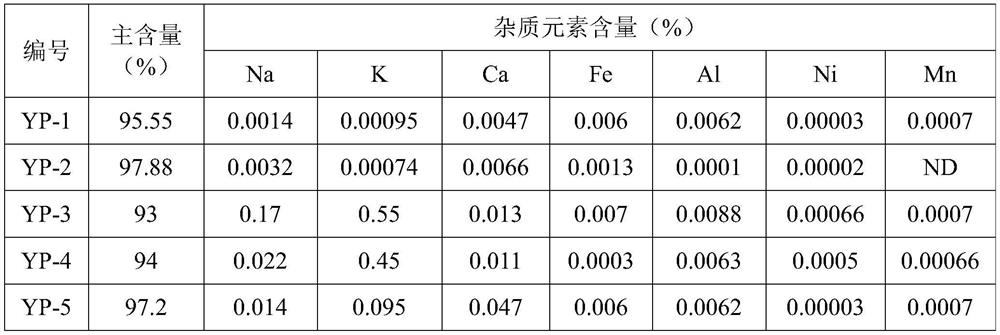

[0039] The composition parameter of gained product is shown in Table 1, and its XRD diffraction pattern ...

Embodiment 2

[0041] Mole ratio Li 2 O:S:N 2 h 4 ·H 2 Weigh lithium hydroxide monohydrate, sulfur powder and hydrazine hydrate in a ratio of O→1:1:2, mix and grind lithium hydroxide monohydrate and sulfur powder evenly, then slowly add hydrazine hydrate into the mixed powder, and add While grinding, until the hydrazine hydrate is added completely. The obtained reaction material is put into a vacuum defoaming barrel, vacuumed to below 0.1MPa, and the reaction is continued until the bubbles are no longer generated, and then the vacuum state is maintained for 4 hours. The valve of the vacuum defoaming barrel is opened until the air pressure reaches normal pressure, and the mixed liquid Transfer to a vacuum freeze dryer, carry out vacuum freeze drying at a low temperature of -60°C and a pressure below 100 Pa for 6 hours, vacuum cap the dried material and take it out to obtain the lithium sulfide product YP-2.

[0042] The composition parameter of gained product is shown in Table 1, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com