Single-component modified silicone flame-retardant sealant and preparation method thereof

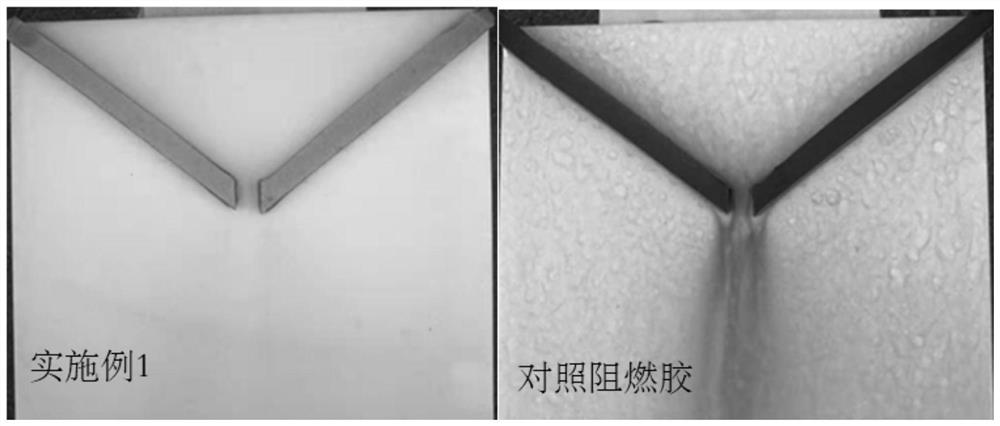

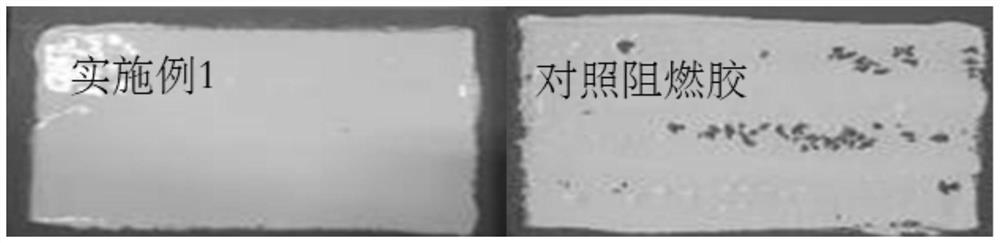

A modified silicon, one-component technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of vertical flow pollution, suffocation and death, and cannot be used for painting. Low requirements for instruments and process conditions, achieving industrialized mass production, good mechanical properties and finishing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

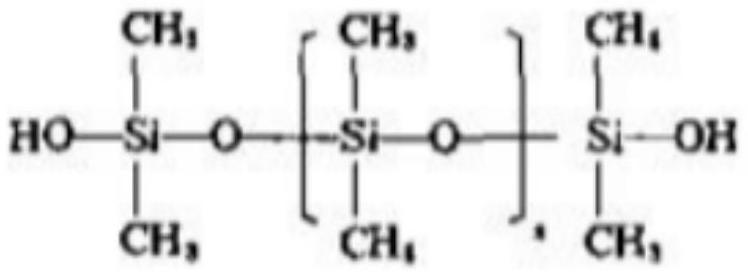

[0037] Examples of the one-component modified silicone flame-retardant sealant of the present invention, the component formulations of the products described in each example are shown in Table 1. The preparation method of each embodiment product is identical, comprises the following steps:

[0038] (1) Add organic resin, UV aging resistance agent, thixotropic agent, antioxidant, plasticizer and color paste into planetary mixer and mix and stir at 10r / min for 5min until uniform to obtain precursor A; in this step, organic resin And the amount of plasticizer added accounts for half of the total content of organic resin and plasticizer in the one-component modified silicone flame retardant sealant component;

[0039] (2) Add filler and flame retardant to the precursor A obtained in step (1) and stir at 25r / min for 30min until uniform, heat to 85°C and depressurize to -0.08MPa, continue to stir for 120min, then cool to 50°C, Get precursor B;

[0040] (3) Add the remaining amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com